Laurentiu Adam, Dorina-Nicolina Isopescu, Loredana Judele, Roxana Dana Bucur, Daniel Lepadatu

ABSTRACT. Waste is a major worldwide problem and its recycling has become mandatory in the current context of the decrease in natural resources. The management of recyclable waste improves the efficiency of any economic activities and the impact on the environment decreases proportionally to the quantities reused. With a significant impact on carbon dioxide emissions, the construction sector is one of the largest consumers of energy and raw materials. Hemp, and other biomass waste, are by-products in agriculture, making important contributions to the development of ecological materials by incorporating important quantities of such recyclable waste. This paper presents a series of different hemp concrete compositions that aim to obtain the optimum ratio between the binder and hemp shiv, in order to determine the inflection point towards which the delimitation can be made between insulating materials and materials with improved mechanical resistance. The importance of the work is given by the fact that, until now, the optimal proportion between the binder and hemp wood chips has not been demonstrated. This turning point must be justified by a variation of the mechanical resistance or a variation of the heat transfer coefficient, through the conductivity of the obtained samples. After preliminary testing, the statistical analysis will allow identification of the specific quantities needed to improve the physical-mechanical performance of the hemp-concrete recipe. Thus, by adding a justified amount of binder, an ecological material based on vegetable waste from agricultural crops is obtained. The material will have thermo-mechanical properties designed for a specific situation, required by the minimum performance imposed by the destination for which it will be made.

Keywords: Hemp-binder ratio; hemp concrete recipe optimisation; statistical analysis; agricultural buildings.

Cite

ALSE and ACS Style

Adam, L.; Isopescu, D.-N.; Judele, L.; Bucur, R.D.; Lepădatu, D. Statistical analysis of preliminary studies for hemp concrete. Journal of Applied Life Sciences and Environment 2022, 55 (2), 145-158.

https://doi.org/10.46909/alse-552052

AMA Style

Adam L, Isopescu D-N, Judele L, Bucur RD, Lepădatu D. Statistical analysis of preliminary studies for hemp concrete. Journal of Applied Life Sciences and Environment. 2022; 55 (2): 145-158.

https://doi.org/10.46909/alse-552052

Chicago/Turabian Style

Adam, Laurentiu, Dorina-Nicolina Isopescu, Loredana Judele, Roxana Dana Bucur, and Daniel Lepădatu. 2022. “Statistical analysis of preliminary studies for hemp concrete” Journal of Applied Life Sciences and Environment 55, no. 2: 145-158.

https://doi.org/10.46909/alse-552052

View full article (HTML)

Statistical Analysis of Preliminary Studies for Hemp Concrete

Laurentiu ADAM1*, Dorina-Nicolina ISOPESCU1, Loredana JUDELE1, Roxana Dana BUCUR2 and Daniel LEPADATU1

1 “Gheorghe Asachi” Technical University of Iasi, Faculty of Civil Engineering and Building Services Bd. D. Mangeron 67, Iasi, 700050, Romania; e-mail: dorina-nicolina.isopescu@academic.tuiasi.ro; ljudele@yahoo.co.uk; daniel.lepadatu@academic.tuiasi.ro

2 Iasi University of Life Sciences, Faculty of Food and Animal Science, Department of Control, expertise and services, 8, Mihail Sadoveanu Alley, 700489, Iasi, Romania; e-mail: rbucur@uaiasi.ro

*Correspondence: laurentiu.adam@student.tuiasi.ro

Received: Oct. 19, 2022. Revised: Nov. 08, 2022. Accepted: Dec. 15, 2022. Published online: Jan. 17, 2023

ABSTRACT. Waste is a major worldwide problem and its recycling has become mandatory in the current context of the decrease in natural resources. The management of recyclable waste improves the efficiency of any economic activities and the impact on the environment decreases proportionally to the quantities reused. With a significant impact on carbon dioxide emissions, the construction sector is one of the largest consumers of energy and raw materials. Hemp, and other biomass waste, are by-products in agriculture, making important contributions to the development of ecological materials by incorporating important quantities of such recyclable waste. This paper presents a series of different hemp concrete compositions that aim to obtain the optimum ratio between the binder and hemp shiv, in order to determine the inflection point towards which the delimitation can be made between insulating materials and materials with improved mechanical resistance. The importance of the work is given by the fact that, until now, the optimal proportion between the binder and hemp wood chips has not been demonstrated. This turning point must be justified by a variation of the mechanical resistance or a variation of the heat transfer coefficient, through the conductivity of the obtained samples. After preliminary testing, the statistical analysis will allow identification of the specific quantities needed to improve the physical-mechanical performance of the hemp-concrete recipe. Thus, by adding a justified amount of binder, an ecological material based on vegetable waste from agricultural crops is obtained. The material will have thermo-mechanical properties designed for a specific situation, required by the minimum performance imposed by the destination for which it will be made.

Keywords: Hemp-binder ratio; hemp concrete recipe optimisation; statistical analysis; agricultural buildings.

INTRODUCTION

The use of hemp dust as a basic material in the production of biodegradable construction materials (Faruk et al., 2012) has its advantages, such as obtaining hygrothermal interior comfort which is superior to conventional construction materials (Tran Le, 2010; Walker et al., 2005). The capacity of hemp to absorb CO2 from the atmosphere, both during the growth of the culture and during the production and use of the material (Pervaiz and Sain, 2003), makes this sustainable resource very useful on an industrial scale (Esmail, 2010). This should be of particular interest to researchers who aim to obtain a composite material with enhanced physico-mechanical properties.

For the construction sector, the most important part of the plant is the shiv, which is the woody part with a high porosity, approximately 90-91% (Redoune, 2022), whose use primarily reduces the amount of aggregates needed to produce concrete. The specific weight of the elements are also affected because the bulk density of the hemp shiv is around 100 kg/m3. The production of hemp concrete consists of mixing the woody part with a quantity of mineral binder (based on hydrated lime, hydraulic lime or cement) and adding water for hydration and homogenisation (Arrizi et al., 2018). Differences were found regarding the physico-mechanical properties of the materials, depending on the amount of water used in the mixture, the mass or volume ratio between the hemp shiv and binder, the method of installation and the degree of compaction, as well as the atmospheric conditions of humidity and temperature to which the construction elements will be exposed (Colinart et al., 2012; Holcroft and Shea, 2015). In the structure of buildings, hemp concrete is used as a non-load-bearing material due to its low values of compression resistance (below 1 MPa), which are directly influenced by the ratio between the mass of the hemp and the mass of the binder (Arnaud and Gourlay, 2012; Williams et al., 2016). In an attempt to optimise physico-mechanical performance, some researchers have highlighted the importance of the binder and the granularity of the base material used in the mixture (Ingrao et al., 2015; Walker et al., 2014). However, an improvement in mechanical resistance inevitably leads to a loss of hygrothermal properties directly proportional to the density, the values of the heat transfer coefficient being in the range 0.05–0.13 W/m⋅K° (Nguyen et al., 2016). Therefore, determining an optimal hemp/binder and water/binder ratio are essential in trying to characterise the physico-mechanical properties of hemp concrete. For this, several hemp concrete recipes were used to make samples that were tested and the values obtained were examined through a preliminary statistical analysis so that later, in subsequent research, a strategy for planned experiments could be adopted to obtain the optimisation of hemp concrete recipes. As part of the testing carried out, values were obtained for tensile strength, compression strength and thermal conductivity coefficient. The results obtained for tensile strength are the ones that provided information about the minimum amount of binder required for the optimal ratio between binder mass and hemp mass. This ratio is important because, for the recipes used in this work, it represents the axis of separation between insulating materials and materials with superior mechanical properties. Future studies will focus on the technological solutions and variations of the recipe, which will optimise the compression resistance to a minimum admissible value for the declaration of the self-supporting material. At the same time, research should keep the thermal conductivity coefficient at the lowest possible values. In order to improve the physical-mechanical performance of hemp concrete, some studies recommend cement replacement with sugarcane bagasse ash (Thomas et al., 2021), straw and husk biomass ash (Kumar et al., 2022), or the addition of marble dust waste (Deepankar, 2018).

MATERIALS AND METHODS

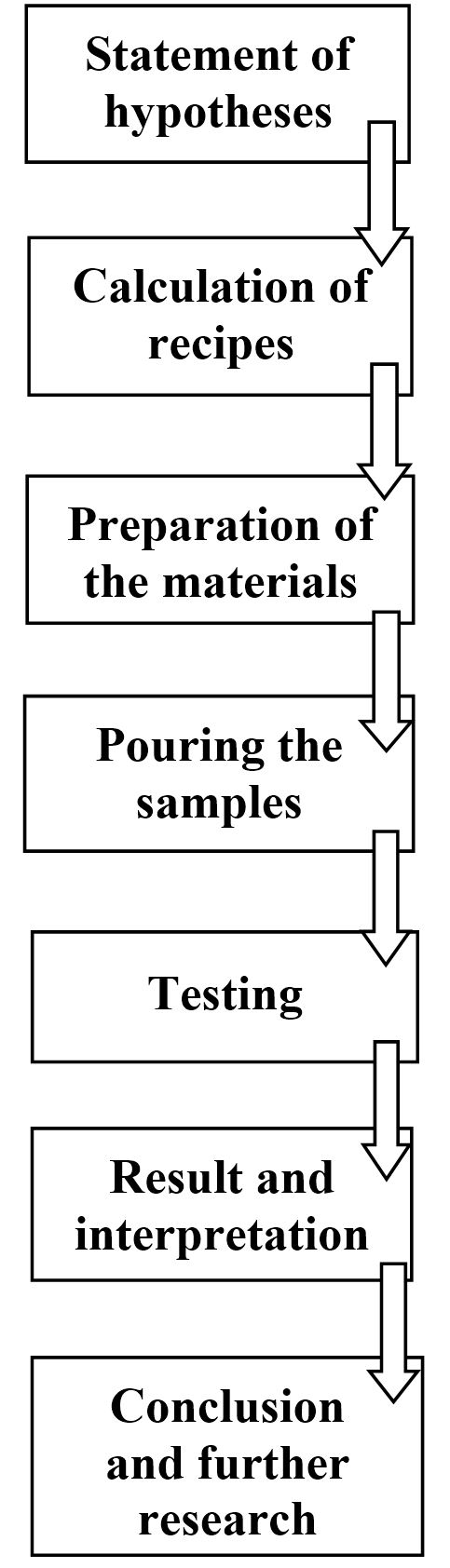

The purpose of this work was to determine the minimum amount of binder needed to cover the hemp wood chips used in recipes for making hemp concrete. The hypothesis from which this research started was that there must be a minimum of mechanical resistance and a minimum thermal conductivity coefficient (that cannot be the same as 0.05 W/m⋅K, which is the thermal conductivity coefficient of the hemp shiv alone). That minimum must be identified by the test results that demonstrate the existence of that inflection point. The preparation of the materials, the making of the samples, the testing of the samples, the interpretation of the results and the statement of the conclusions were caried out according to the flowchart given as Figure 1.

The density of the hemp concrete composite material cannot be lower than the specific density of the base material (hemp wood chips), which is approximately 100-110 kg/m3.

The coefficient of thermal conductivity cannot be lower than 0.05 W/m⋅K.

The quantities of materials in the recipe were calculated starting from the determination of the volume of voids contained in a container in which a mass of hemp equal to 55 g was initially added. Hence, the bulk density of the base material was 110 kg/m3. The hemp granules were saturated with water and added to the dish. Water was poured over the bowl until the hemp granules were covered. The measured volume of water was 56% of the volume occupied by the granules.

The recipe used 0.0-4.5 cm granulation hemp shredding (Ratza variety), specialised for the production of wood pulp. The proportion of 48% hydraulic lime NHL 3.5 and 52% hydrated lime CL80-S was used for the binder mix. The test pieces used for casting the samples were prismatic, with dimensions of 40 x 40 x 160 mm. The casting of the parts was carried out in the following order: hydrating the binder mix with water in an amount equal to 55% of the weight of the dry binder (included in the recipe), pre-moistening the hemp mass with an equal amount of water, adding the pre-moistened hemp shreds over the hydrated binder and mixing until homogenisation. The mixing time should not exceed 10 minutes.

The samples were tested to determine the thermal conductivity coefficient, the tensile strength and the compressive strength.

The materials used in the mixture included hemp powder, specifically obtained from the stems of the Cannabis Sativa species (Ratza variety) for biomass production, which was decorticated after harvesting and drying. The separation of the fiber from the woody part of the stem, using an electric device (Figure 2), was carried out on a support table with four knives placed helically on a drum driven by a shaft and a flywheel mounted on the shaft.

After the decortication process, the hemp shiv (Figure 3) was sorted from the uneven parts and coarse fibres, and the dust and particles of earth or stones left over from harvesting were sifted out. The binder used was a mixture made from 52% hydrated lime (type CL80-S) and 48% hydraulic lime (NHL 3.5); the resulting density of the mixed binder was 745 kg/m3.

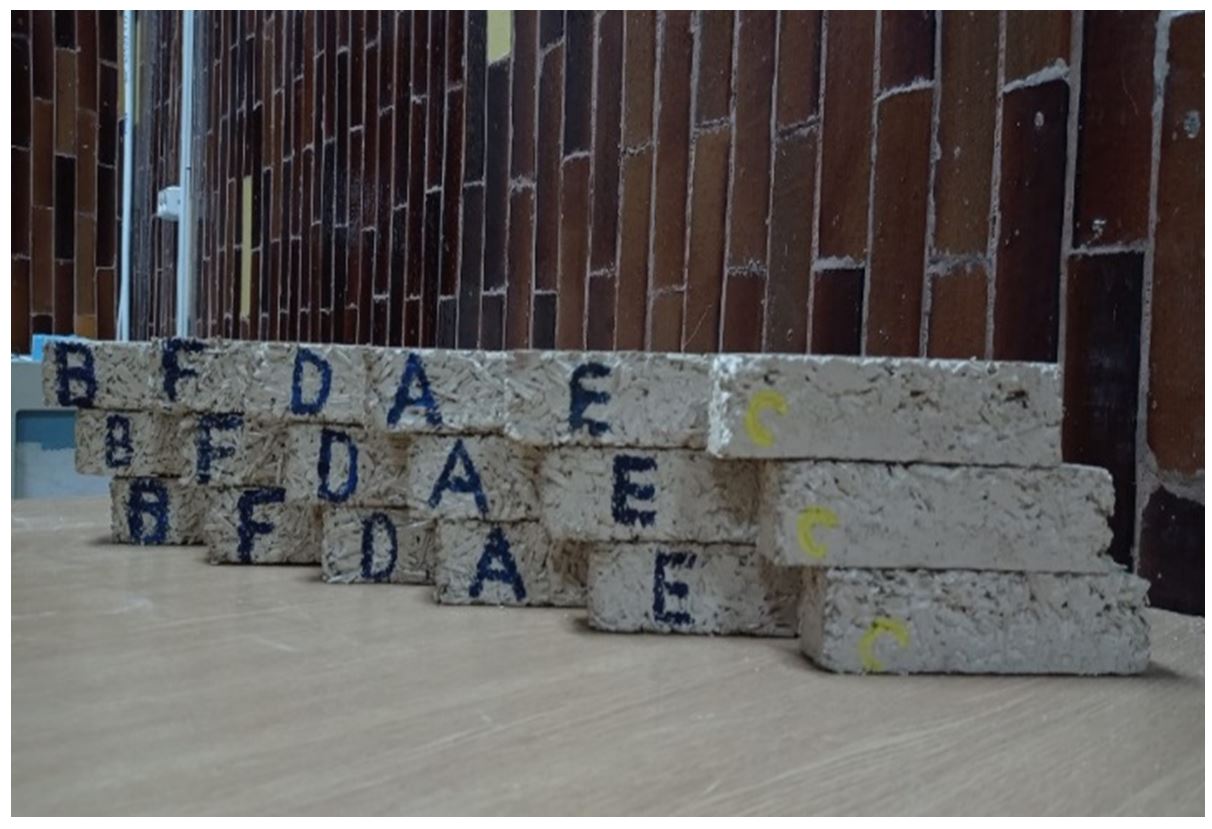

The method used to make the mixture to obtain hemp concrete was as described below. First of all, the hemp powder was pre-wetted with a quantity of water equal to the mass of the dry powder entered into the mixture. Secondly, the binder was prepared by mixing dry state hydrated lime (CL80-S) with hydraulic lime (NHL 3.5) and the binder mix was hydrated with a volume of water equal to 55% of the mass binder. The third step was to add the hydrated binder mixture to the pre-wetted hemp powder and mixing it until all the hemp particles were uniformly wrapped in the binder. The time taken to make the mixture should not exceed 15 minutes. For each recipe, three prismatic samples (Figure 4), with the dimensions 40 x 40 x 160 mm, and 3 cylindrical samples (Figure 5), with the dimensions 50 mm in diameter and 50 mm in height, were cast. A total of 18 prismatic samples and 18 cylindrical samples were made.

The recipes used for casting the samples are presented in Table 1. The quantity of water used in the recipes was calculated by considering the mass of the hemp and the mass of the binder. For every 110 g of hemp woody parts added, 110 g of water was added, to pre-wet the hemp and set the mixture. A quantity of water, equal to 55% of the mas of the hydrated lime and hydraulic lime, was added to hydrate the binder mix.

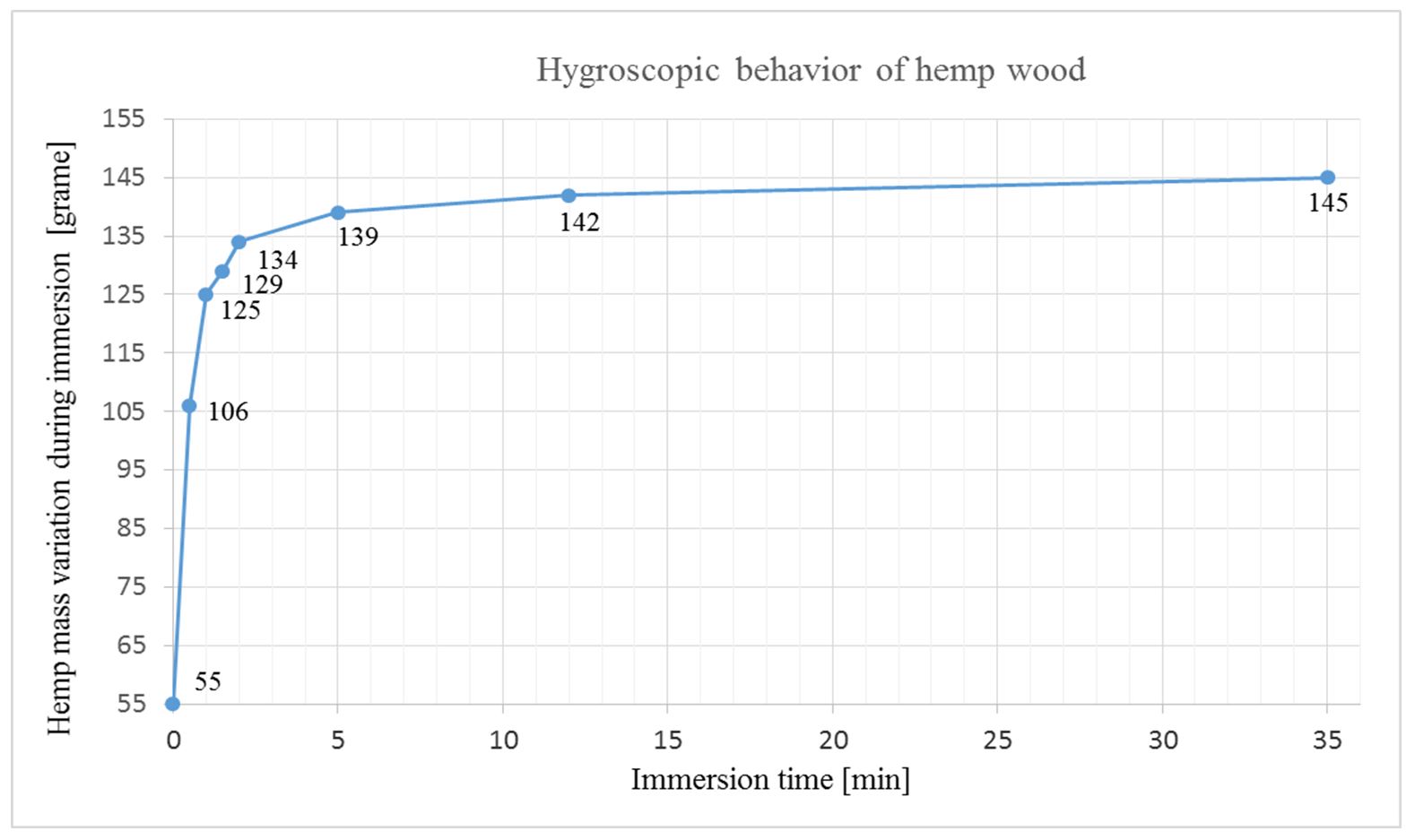

The process of pre-wetting the hemp particles was carried out to remove the fine dust from the surface of the granules. It also performs an even more important role, as it influences the strong hygroscopic behaviour of the hemp, as shown in Figure 6.

It can be seen that, after 5 minutes, the mass of the hemp wood increases from 55 g to 139 g, which means the mass of absorbed water is equal to 152% of the mass of the dry hemp measured before starting the immersion. The strong hygroscopic character must be taken into account when establishing the mixing technology because it can influence the amount of water required in the mixture, with a negative effect on the mechanical strength. For this, it is necessary to identify variations in the mixture that can limit the absorption of free water. The hemp wood chips absorb a quantity of water equal to 93% of the maximum absorption capacity that it can achieve in 35 minutes. The mixing technology must allow the mixing time to be limited to a maximum of 10 minutes and pre-moistening must be carried out because, otherwise, the water used to hydrate the binder can be absorbed by the hemp mass, which leads to a lack of sufficient hydration of the binder with adverse effects on mechanical resistances. At the same time, too much water being used for pre-moistening can lead to over-hydration of the binder. That is why, when making the recipes, the amount of water used for pre-moistening was equal to the mass of dry hemp and the hydration of the binder was carried out separately, before the hemp was added.

Table 1

Recipes used for casting the samples

|

Sample |

Hemp woody parts 0.0-4.5 cm (g) |

Hydrated lime CL80-S (g) |

Hydraulic lime NHL 3.5 (g) |

Water (ml) |

Total amount of binder mix (g) |

|

B |

110 |

90.0 |

84 |

206 |

174.0 |

|

F |

110 |

112.5 |

105 |

230 |

217.5 |

|

D |

110 |

135.0 |

126 |

254 |

261.0 |

|

A |

110 |

150.0 |

140 |

270 |

290.0 |

|

E |

110 |

187.5 |

175 |

309 |

362.5 |

|

C |

110 |

225.0 |

210 |

349 |

435.0 |

RESULTS AND DISCUSSION

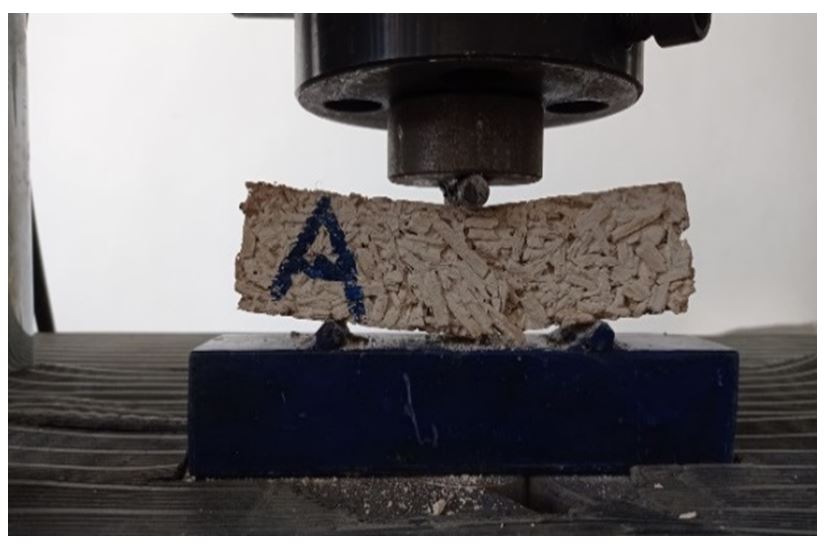

The measurement of the heat transfer coefficient (Figure 7) was carried out after 28 days from the casting of the samples, using the portable ISO Met 2114 system. After testing the samples, to determine the split tensile force (Figure 8) and the compression force (Figure 9), the values obtained were centralised, as presented in Table 2.

Analysis of the values obtained for tensile strength (Table 2) reveal that, for the first three recipes (B, F and D), the values are decreasing. Although the binder content increases from recipe B to recipe F and D, the tensile strength decreases. A possible explanation could be that, in order to compact the mixture mass in the prismatic shapes, a higher compaction force was used for recipe B, a force that gradually decreased for recipe F and D. As a result, the tensile strength was influenced by the degree of compaction of the hemp and not because of the percentage of the binder. On the other hand, recipe A shows an increase in tensile strength, which increases exponentially with the increase in the amount of binder used in recipe E and C. This demonstrates that, in order to have a significant variation in tensile strength, the minimum ratio of hemp:binder has to be 1:3. This is only valid, however, if the same binder mix is used with the same density as the one used in this test.

Statistical analysis (Montgomery et al., 2019; William et al., 2016; Barbuta et al., 2015; Judele et al., 2015; Amarandei et al., 2011; Lepadatu et al., 2008) is a complex evaluation, analysis and modelling technique, through which the user can determine the trends and particularities of data series. This information can help the decision-making process if it is exploited correctly and used for the purpose for which it was made. Interpretation requires experience, flair and a thorough knowledge of several subfields. In this work, analysis was carried out on the mechanical characteristics (Table 2) of the hemp concrete, with the aim of evaluating the trends and evolution of various configurations of the proposed recipes.

Table 3 shows the basic statistics for these data. The values of Kurtois coefficient show us that the results of the analysis for the three mechanical characteristics are not aberrant.

The standard deviations show that most of the values obtained for the three mechanical characteristics fall within the ranges centring on the average value. Thus, the values for split tensile strength and compressive strength are mostly within this range while, for the thermal conductivity coefficient, they are more dispersed; some values exceed this range, determined by two values of the standard deviation (centred on the average value). It can be concluded that the probability of obtaining a material with good hygro-thermal properties is less than that of obtaining the same material with the expected mechanical characteristics.

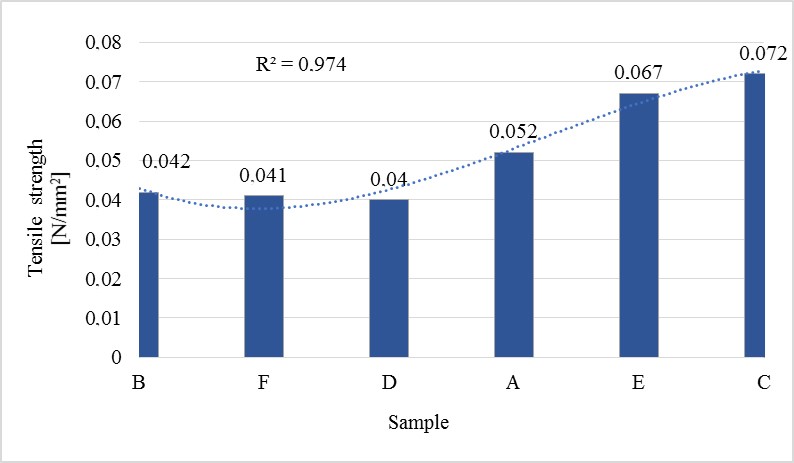

The tensile strength (Figure 10) decreases very slightly, from 0.042 in sample B to 0.040 in sample D, and then increases to a maximum value of 0.072 in sample C. Through mathematical regression, a polynomial equation can be determined that approximates these values as closely as possible to the results. The degree of approximation is given by the value of R square – R2, which must be as close as possible to 1. For tensile strength, it can be observed that the degree of approximation of the polynomial equation that approximates the curve is close to 1. A unimodal distribution, on the curve that approximates the tensile strength variation, is also observed, with a minimum of 0.042-0.052.

Table 2

The average values of physico-mechanical properties

|

Sample |

Hemp woody parts 0.0-4.5 cm (g) |

Hydrated lime CL80-S (g) |

Hydraulic lime NHL 3.5 (g) |

Water (ml) |

Total amount of binder mix (g) |

Bending tensile strength (N/mm2) |

Compre-ssion strength (N/mm2) |

Heat transfer coefficient λ (W/m⋅K°) |

|

B |

110 |

90.0 |

84 |

206 |

174.0 |

0.042 |

0.0642 |

0.0508 |

|

F |

110 |

112.5 |

105 |

230 |

217.5 |

0.041 |

0.1087 |

0.0609 |

|

D |

110 |

135.0 |

126 |

254 |

261.0 |

0.040 |

0.1263 |

0.0649 |

|

A |

110 |

150.0 |

140 |

270 |

290.0 |

0.052 |

0.1272 |

0.0743 |

|

E |

110 |

187.5 |

175 |

309 |

362.5 |

0.067 |

0.2648 |

0.0825 |

|

C |

110 |

225.0 |

210 |

349 |

435.0 |

0.072 |

0.8250 |

0.0965 |

Table 3

Descriptive statistics of the mechanical characteristics of hemp concrete

|

Sample |

Split tensile Strength (N/mm2) |

Compressive strength (N/mm2) |

Heat transfer coefficient λ (W/m⋅K°) |

|

Mean |

0.052 |

0.253 |

0.072 |

|

Standard Error |

0.006 |

0.118 |

0.007 |

|

Median |

0.047 |

0.127 |

0.070 |

|

Standard Deviation |

0.014 |

0.288 |

0.016 |

|

Sample Variance |

0.000 |

0.083 |

0.000 |

|

Kurtosis |

-1.835 |

4.838 |

-0.389 |

|

Skewness |

0.682 |

2.175 |

0.413 |

|

Range |

0.032 |

0.761 |

0.046 |

|

Minimum |

0.040 |

0.064 |

0.051 |

|

Maximum |

0.072 |

0.825 |

0.097 |

|

Sum |

0.314 |

1.516 |

0.430 |

|

Count |

6.000 |

6.000 |

6.000 |

|

Confidence Level (95.0%) |

0.015 |

0.303 |

0.017 |

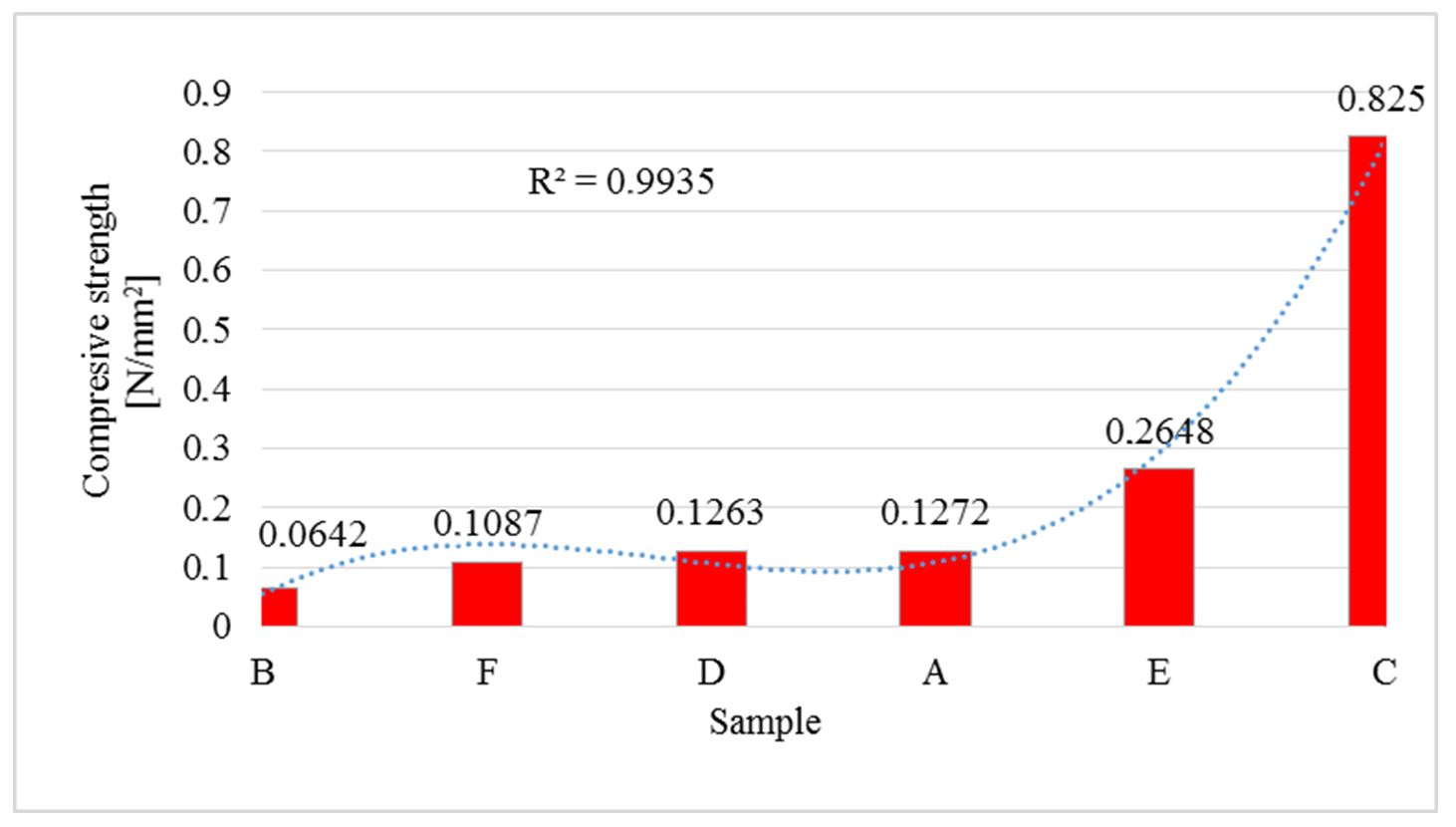

Compressive strength (Figure 11) only exhibits increasing values: samples B, F and D are more rigid and samples A, E and C are more flexible. Instead, they have better tensile strength. The polynomial curve that approximates the tensile strength behaviour within the analysed domain has a degree of approximation given by R2 = 0.994, which shows that it is very good. Its maximum value can be equal to 1.

The approximation curve has a bimodal distribution, with an estimated minimum located between 0.1263 and 0.2648 and a maximum located between 0.0642 and 0.1263. The thermal conductivity coefficient (Figure 12) constantly increases, which causes the material to lose its hygro-thermal properties, along with a gain in tensile and compression strength. The degree of approximation R2 = 1 indicates that this polynomial curve perfectly describes its behaviour in the analysed domain.

For the thermal conductivity coefficient diagram, the fitted curve becomes multimodal, with four localised extreme points due to the variations of the adopted recipes.

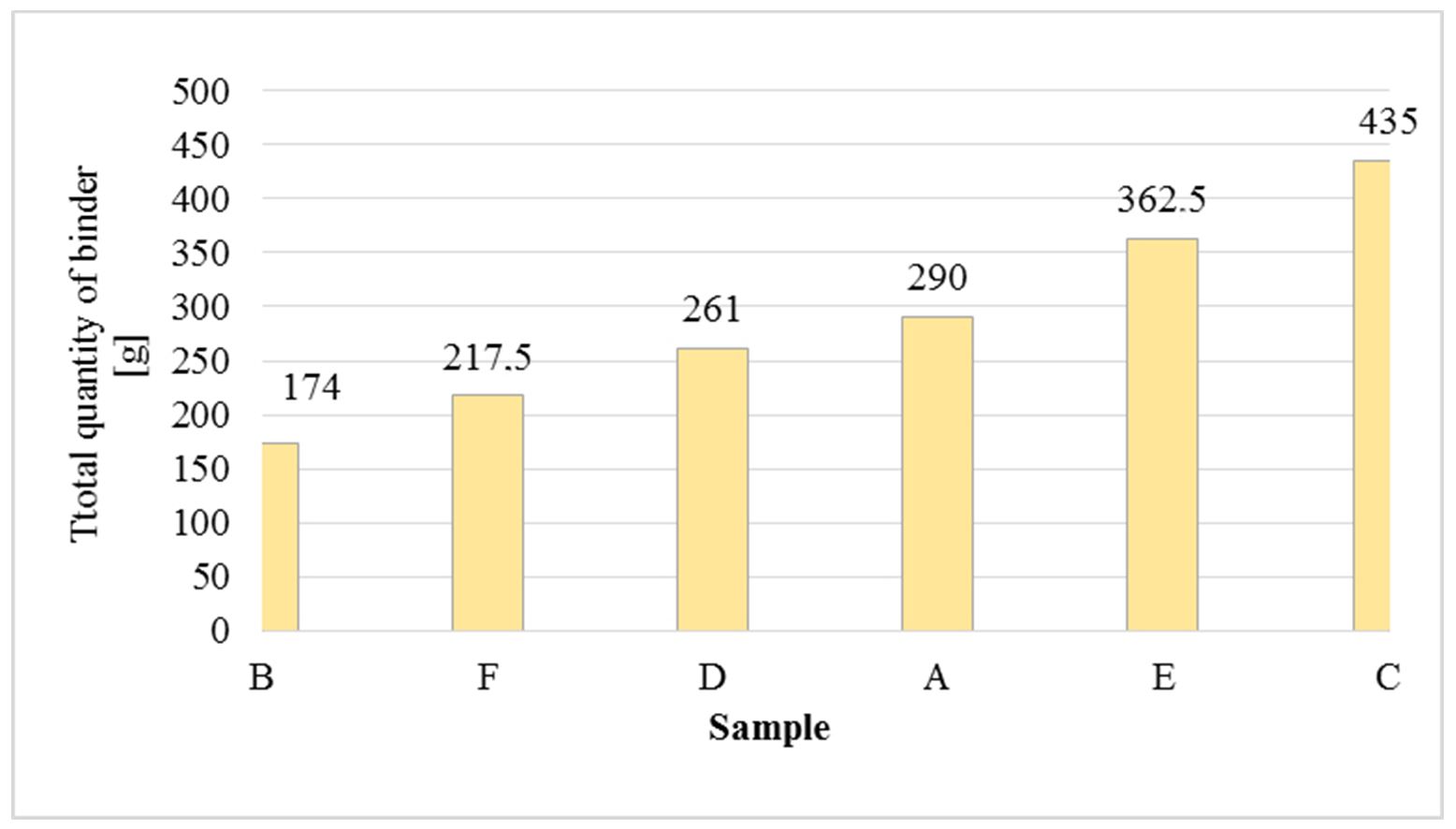

The analysis also presents the total amount of the binder (Figure 13), which is an essential component of the analysed recipes. It can be observed that this increases from a minimum of 174 g (for recipe B) to 435 grams (for recipe C), which represents a more than double increase. Comparing the increases in the quantity of binder mix with the increases in compressive strength, it can be observed that these mechanical properties increased by 12.85 times (from 0.0642 in sample B to 0.8250 in sample C). Three recipes are within the range 200-300 g and maintain their mechanical characteristics at normal values without spectacular jumps.

Analysis of the mechanical characteristics leads to the improvement of the selection process and variations of the parameters of the concrete recipes with hemp and, implicitly, to the maximisation of the chance of their optimisation, reducing the experimentation costs.

The statistical analysis presented helps us to understand the evolution of the mechanical characteristics of the proposed recipes but the mathematical modelling allows prediction of each individual size and their subsequent optimisation.

CONCLUSIONS

The use of hemp wood as a basic material in the production of ecological concrete requires knowledge of the thermo-hygro-mechanical characteristics of the hemp wood raw material obtained after the decortication of the stems. In order to use hemp shiv in the creation of specialised concrete recipes based on thermo-mechanical properties, the minimum amount of binder needed to ensure the coverage of the specific surface of the powder granules used in the mixture, must be determined. This will result in the minimum volume of binder and, furthermore, the optimal ratio between water and binder. The results demonstrated that there is a causal link between the increase in the density of the sample and the exponential increase in mechanical resistance. At the same time, the increase in the density of the parts also determines a directly proportional increase in the coefficient of thermal conductivity. The biggest influence in determining the density of the samples is the specific weight of the binder or the binder mix used. Thus, in order to optimise the physical-mechanical properties of hemp concrete, research must focus on identifying binders with low densities.

The strong hygroscopic character must be taken into account when establishing the mixing technology because it can influence the amount of water required in the final recipe, having a negative effect on the mechanical strength. For this, it is necessary to identify variants of the mixture that limit the absorption of free water in the powdered mass.

The statistical analysis used provided us with a powerful analysis tool that summarises the information about the analysed data and assures us of their character, which is not aberrant. It is a necessary step in the analysis and objective interpretation of the experimental results which, in certain special completely natural situations, can lead the user to false conclusions. The evolution of the experimentally obtained physical-mechanical characteristics can be much more easily described and analysed using statistical quantities, since they were specially designed to calibrate data sets and to bring the necessary information to the operator for their acceptance or rejection.

The identification of the parameters in the recipe that can influence the physical-mechanical characteristics of the mixture can only be achieved with advanced experimental planning, using the design of experimental methods which, through a minimum number of experiments configured with matrices with complex mathematical properties, bring maximum information to the user about their influence on mechanical characteristics and can generate mathematical functions capable of predicting these characteristics for the analysed fields of study.

Author Contributions: conceptualization, D.N.I.; methodology, D.N.I., D.L.; investigation, L.A., D.L.; formal analisys, L.A, L.J.; data curation,L.A., R.D.B.; writing—original draft preparation, L.A., R.D.B.; writing—review and editing,L. A., D.L, L.J; supervision, D.N.I. All authors have read and agreed to the published version of the manuscript.

Funding: There was no external funding for this study.

Conflicts of Interest: The author confirms that there is no conflict of interest regarding the work presented in this article.

REFERENCES

Amarandei, C.M.; Lepadatu, D.; Caraiman, S. Improving the Design of Parallel Applications using Statistical Methods. Journal of Applied Sciences. 2011, 11, 932-942. https://scialert.net/abstract/?doi=jas.2011.932.942.

Arizzi, A.; Brümmer, M.; Martín-Sánchez, I.; Molina, E.; Cultrone, G. Optimization of lime and clay-based hemp-concrete wall formulations for a successful lime rendering. Construction and Building Materials. 2018, 184, 76-86. https://doi.org/10.1016/j.conbuildmat.2018.06.225.

Barbuta, M.; Marin, E.; Cimpeanu, S.M.; Paraschiv, G.; Lepadatu, D; Bucur, R.D. Statistical Analysis of the Tensile Strength of Coal Fly Ash Concrete with Fibers Using Central Composite Design. Advances in Materials Science and Engineering. 2015, 7. http://dx.doi.org/10.1155/2015/486232.

Bevan, R.; Woolley, T. Hemp lime construction, in: A Guide to Building with Hemp Lime Composites, HIS BRE Press, Bracknell, UK, 2008, 41–42. https://www.brebookshop.com/samples/321427.pdf.

Ingrao, C.; Lo Giudice, A.; Bacenetti, J.; Tricase, C.; Dotelli, G.; Fiala, M.; Siracusa, V.; Mbohwa, C. Energy and environmental assessment of industrial hemp for building applications: A review. Renewable and Sustainable Energy Reviews. 2015, 51, 29–42. https://doi.org/10.1016/j.rser.2015.06.002.

Colinart, T.; Glouannec, P.; Chauvelon, P. Influence of the setting process and the formulation on the drying of hemp concrete. Construction and Building Materials. 2012, 30, 372–380. https://doi.org/10.1016/j.conbuildmat.2011.12.030.

Ashish, D.K. Feasibility of waste marble powder in concrete as partial substitution of cement and sand amalgam for sustainable growth. Journal of Building Engineering. 2018, 15, 236-242. https://doi.org/10.1016/j.jobe.2017.11.024.

Esmail, A.M. Cannabis Sativa: an optimization study for ROI, Massachusetts Inst. Technol. 2010.

Faruk, O.; Bledzki, A.K.; Fink, H.-P.; Sain, M. Biocomposites reinforced with natural fibres: 2000–2010. Progress in Polymer Science. 2012, 37, 1552-1596. https://doi.org/10.1016/j.progpolymsci.2012.04.003.

Holcroft, N.; Shea, A. Effect of compaction on moisture buffering of hemp-lime insulation, in: S. Amziane, M. Sonebi (Eds.), Proceedings of the 1st International Conference on Bio-Based Building Materials, Charlet K; RILEM Publications S.A.R.L., 2015.

Judele, L.; Lepadatu, D.; Plian, D.; Rosu, A.R. Estimated Adhesiveness of Asphaltic Bitumen to Natural Aggregtes Using Statistical Regression. International Journal of Structural Analysis & Design. 2015, 2, 136-140.

Kumar, S.; Deepankar, A.; Kumar, A.; Rudžionis, Ž. A review on sustainable use of agricultural straw and husk biomass ashes: Transitioning towards low carbon economy. Science of The Total Environment. 2022, 838, 156407. https://doi.org/10.1016/j.scitotenv.2022.156407.

Arnaud, L.; Gourlay, E. Experimental study of parameters influencing mechanical properties of hemp concretes. Construction and Building Materials. 2012, 28, 50-56. https://doi.org/10.1016/j.conbuildmat.2011.07.052.

Lepadatu, D.; Bliuc, I.; Baran, I. Statistical process control concerning the glazed areas influence on the energy efficiency of buildings. Bulletin of the Polytechnic Institute of Iassy. 2008, 2, 43-52.

Mendenhall, W.M.; Terry, L. Sincich, Statistics for Engineering and the Sciences. Published by Chapman and Hall/CRC. 2016.

Montgomery, D.C.; Runger, G.C., Applied Statistics and Probability for Engineers, John Wiley & Sons; 7th Edition, 2019.

Nguyen, S.T.; Tran-Le, A.D.; Vu, M.N.; To, Q.D.; Douzane, O.; Langlet, T. Modeling thermal conductivity of hemp insulation material: A multi-scale homogenization approach. Building and Environment. 2016, 107, 127-134. https://doi.org/10.1016/j.buildenv.2016.07.026.

Pervaiz, M.; Sain, M.M. Carbon storage potential in natural fiber composites. Resources, Conservation and Recycling. 2003, 39, 325-340. https://doi.org/10.1016/S0921-3449(02)00173-8.

Pham, H. Springer Handbook of Engineering Statistics, Published by Springer London, 2006.

Thomas, B.S.; Yang, J.; Bahurudeen, A.; Abdalla, J.A.; Hawileh, R.A.; Hamada, H.M.; Nazara, S.; Jittin, V.; Ashish, D.K. Sugarcane bagasse ash as supplementary cementitious material in concrete – a review. Materials Today Sustainability. 2021, 15, 100086. https://doi.org/10.1016/j.mtsust.2021.100086.

Tran Le, A.D.; Maalouf, C.; Mai, T.H.; Wurtz, E.; Collet, F. Transient hygrothermal behavior of a hemp concrete building envelope. Energy Build. 2010, 42, 1797-1806. https://doi.org/10.1016/j.enbuild.2010.05.016.

Walker, P.; Keable, R.; Martin, J.; Maniatidis, V. Rammed earth, in: Design and construction guidelines, BRE Bookshop, Watford, UK, 2005, 70-72.

Walker, R.; Pavia, S.; Mitchell, R. Mechanical properties and durability of hemp-lime concretes. Construction and Building Materials. 2014, 61, 340-348. https://doi.org/10.1016/j.conbuildmat.2014.02.065.

Williams, J.; Lawrence, M.; Walker, P.A. method for the assessment of the internal structure of bio-aggregate concretes. Construction and Building Materials. 2016, 116, 45-51. https://doi.org/10.1016/j.conbuildmat.2016.04.088,

Zerrouki, R.; Benazzouk, A.; Courty, M.; Ben Hamed, H. Potential use of matakaolin as a partial replacement of preformulated lime binder to improve durability of hemp concrete under cyclic wetting/ drying aging. Construction and Building Material. 2022, 333, 1-17. https://doi.org/10.1016/j.conbuildmat.2022.127389.

Academic Editor: Prof. Dr. Maria Harja

Publisher Note: Regarding jurisdictional assertions in published maps and institutional affiliations ALSE maintain neutrality.

Adam Laurențiu, Bucur Roxana Dana, Isopescu Dorina-Nicolina, Judele Loredana, Lepadatu Daniel