Özlem Avşar, Emine Karademir

ABSTRACT. Decreasing water availability for cotton production has compelled researchers to engage in studies about rising water use efficiency by improving water management. The impacts of different irrigation levels on the fibre qualities of drip-irrigated cotton were evaluated in Diyarbakır, Southeast Anatolia Region of Turkiye. Three cotton varieties, ‘Stoneville 468’ (ST 468), ‘FiberMax 832’ (FM 832), and ‘Kartanesi’, and three levels of irrigation were tested in 2017 and 2018. Treatments were I 50 (50% water stress), I 75 (25% water stress), and the fully irrigated treatment I 100, which was obtained from Class-A pan evaporation. According to the two-year results of the study, water stress caused a decline in fineness, length, strength, elongation, uniformity ratio, and spinning consistency index (SCI) values of fibre, while fibre yellowness and short fibre ratio values increased. Fibre brightness was not affected by water stress. There were significant differences among varieties concerning quality parameters. FM 832 has come to the fore with regard to fibre fineness, length, strength, uniformity, yellowness, reflectance, and spinning consistency index.

Keywords: Cotton; water stress; fibre quality.

Cite

ALSE and ACS Style

Avşar, O.; Karademir, E. Evaluation of quality parameters in cotton production (Gossypium hirsutum L.) under water stress conditions. Journal of Applied Life Sciences and Environment 2022, 55(1), 45-61.

https://doi.org/10.46909/alse-551045

AMA Style

Avşar O, Karademir E. Evaluation of quality parameters in cotton production (Gossypium hirsutum L.) under water stress conditions. Journal of Applied Life Sciences and Environment. 2022; 55(1): 45-61.

https://doi.org/10.46909/alse-551045

Chicago/Turabian Style

Avşar, Özlem, and Emine Karademir. 2022. “Evaluation of quality parameters in cotton production (Gossypium hirsutum L.) under water stress conditions” Journal of Applied Life Sciences and Environment 55, no. 1: 45-61.

https://doi.org/10.46909/alse-551045

View full article (HTML)

Evaluation of Quality Parameters in Cotton Production (Gossypium hirsutum L.) Under Water Stress Conditions

Özlem AVŞAR1,*and Emine KARADEMİR2

1 GAP International Agricultural Research and Training Center, Diyarbakır, Turkiye

2 Siirt University, Siirt, Turkiye, email: eminekarademir@siirt.edu.tr

*Correspondence: ozlem.avsar@tarimorman.gov.tr

Received: Aug. 29, 2022. Revised: Oct. 12, 2022. Accepted: Nov. 8, 2022. Published online: Nov. 14, 2022

ABSTRACT. Decreasing water availability for cotton production has compelled researchers to engage in studies about rising water use efficiency by improving water management. The impacts of different irrigation levels on the fibre qualities of drip-irrigated cotton were evaluated in Diyarbakır, Southeast Anatolia Region of Turkiye. Three cotton varieties, ‘Stoneville 468’ (ST 468), ‘FiberMax 832’ (FM 832), and ‘Kartanesi’, and three levels of irrigation were tested in 2017 and 2018. Treatments were I 50 (50% water stress), I 75 (25% water stress), and the fully irrigated treatment I 100, which was obtained from Class-A pan evaporation. According to the two-year results of the study, water stress caused a decline in fineness, length, strength, elongation, uniformity ratio, and spinning consistency index (SCI) values of fibre, while fibre yellowness and short fibre ratio values increased. Fibre brightness was not affected by water stress. There were significant differences among varieties concerning quality parameters. FM 832 has come to the fore with regard to fibre fineness, length, strength, uniformity, yellowness, reflectance, and spinning consistency index.

Keywords: Cotton; water stress; fibre quality.

INTRODUCTION

Cotton (Gossypium hirsutum L.) is the most significant fibre crop in the world, meeting the natural fibre needs of the textile industry (Rehman and Azhar, 2021). Cotton cultivation has significant economic value, and it represents an important income for large- and small-scale farmers, especially in semi-arid regions.

Cotton production in the world is around 25.5 million tonnes in an area of 32,636,000 hectares. The top cotton-producing countries are China (5,730,000 tonnes), India (5,366,000 tonnes) and the USA (3,815,000). In Turkey, cotton cultivation occurs in an area of 480,000 hectares, and 833,000 tonnes of cotton fibre are produced (ICAC, 2022).

As a cellulose-based polymer, 70% cotton is used in cloth and home textiles, while the residue is converted to industrial products. The portion of cotton used in the clothing and home furnishing trade increased from 34% in the 1970s to more than 60% today. It can be used predominantly in every type of apparel due to its low price, comfort, and mechanical eligibility. Absorbing moisture well, being breathable, and having less toxic and hypoallergenic features make cotton a perfect material for fabric use (Khanzada et al., 2020).

In terms of processing, cotton is the raw material of the gin industry; the textile industry uses its fibre, the oil and feed industry uses its seed, and the paper industry uses its linter. As an alternative to petroleum, the oil obtained from cotton seed is utilised as a raw material in biodiesel production in increasing amounts. In addition, population growth and rising living standards also increase the demand for cotton fibres.

Due to water scarcity in the global world, food production requirements and climate change are interrelated. Cotton is an essential source of natural fibre; however, the production of cotton is adversely affected by drought stress. As a result of the greenhouse effect, global warming creates an unpredictable situation in water distribution, which means that some regions will receive unbalanced precipitation. The most effective use of existing water resources is the most important solution to be implemented by countries suffering from water shortages.

To use water efficiently in agriculture, important precautions should be taken, especially in irrigating areas in a conscious way and with proper techniques. Among all irrigation methods, drip irrigation is one of the most important systems for agricultural sustainability, and it is efficient at 90–95% water use efficiency for plants (Tunalı et al., 2013). The application of drip irrigation and fertigation in cotton production has increased enormously because of government subsidies. Compared to conventional methods, drip irrigation and fertigation techniques are more complex. Class A evaporation containers are widely used in drip irrigation and irrigation water calculations due to their low cost, data, and ease of use (Orta et al., 1997).

Determining the effects of precipitation and temperature on cotton yield and quality parameters and water use efficiency (WUE) during the growing season under the conditions of limited irrigation management practices during different growth stages may enable the observation of efficient irrigation management strategies for the Southeast Anatolia Region.

Generally, deep-rooted plants are more tolerant than shallow-rooted plants, which provides more time to irrigate cotton plants. For this reason, the first irrigation is usually performed forty-forty-five days after the sowing date, which leads to deeper roots in searching for available water (Rehman et al., 2017).

The impacts of water deficiency on the fibre quality parameters of cotton have been investigated in many studies. Some authors have emphasised the negative effects or no effect of a decreased amount of irrigation water on fibre quality (Pettigrew, 2004; Snowden et al., 2013), while others have stated a positive effect for some genotypes (Bradow and Davidonis, 2010). In the study conducted by Başal et al. (2009), there was no significant difference in fibre length, fineness, uniformity index, and elongation between the 100% and 75% irrigation treatments.

The aim of this study was to determine the impact of different irrigation levels on fibre quality characteristics in three different cotton varieties. The results of this trial will also be beneficial for decision makers regarding water administration.

MATERIALS AND METHODS

The trial was conducted during the 2017–2018 growing seasons in the research field of the GAP International Agricultural Research and Training Center (GAPUTAEM) Diyarbakır, Turkey.

Soil Properties of the Trial Area

The trial area was plain and poor in terms of organic matter. No salinity problems were detected in the experimental area. Due to the high amount of clay minerals, the soil profiles expand and swell in winter, and deep cracks descend 80-90 cm from the surface in summer (Gürsoy et al., 2006).

Soil samples were collected from the 0–30 cm soil layer with the help of an auger, and analyses of the trial field were examined in the GAPUTAEM Laboratory. The analysis results are given in Table 1.

Table 1

Soil properties of the research area

|

Texture |

Clay-Loam (C-L) |

|

EC (dS m−1) |

1.27 |

|

pH |

8.10 |

|

CaC03 (%) |

11.46 |

|

P2O5 (kg ha−1) |

3.21 |

|

K2O (kg ha−1) |

243 |

|

Organic Matter (%) |

0.98 |

|

Bulk Density (g/cm3) |

1.19 |

The continental climate is dominant in Diyarbakir where the trial was carried out. The annual rainfall average was 487 mm, mainly during the winter and spring seasons.

The meteorological data obtained from the weather station located in Diyarbakır province and the long-term averages of the years in which the research was conducted are given in Table 2. As shown in Table 2, the maximum temperature values of June, July, August, and September in 2017 and 2018, when the experiment was carried out, were above the long-term average, while the precipitation amount in April 2017 and May and October 2018 was above the long-term average. The relative humidity of July, August, and September in both years of the experiment was below average for long years.

Plant Materials

‘Stoneville 468’ (ST 468) (Figure 1), ‘FiberMax 832’ (FM 832) (Figure 2), and ‘Kartanesi’ (Figure 3) cotton varieties were used in this study.

Experimental Design

The experiment was arranged as split plots in randomised complete blocks with four replications. Each plot consisted of four rows. Data were analysed with JMP statistical software (SAS Institute, Cary, NC), and variance tables were tested with analysis of variance (ANOVA).

Irrigation Treatments

The irrigation system consists of a control unit (hydrocyclone, sand-gravel filter, disk filter, fertiliser tank, water flow metres), main pipeline, manifold pipelines, lateral pipelines, and drippers. Irrigation water was supplied with the help of a motor pump working with electrical energy.

Water was distributed to the plots by the irrigation system with 32 mm PE main and manifold pipes and a 16 mm diameter self-contained lateral pipe (in-line) with a pressure regulator. Drippers with 25 cm spacing were installed with 2 L h−1 of irrigation capacity. One lateral pipe irrigated a cotton row; thus, the lateral spacing was 70 cm. The sowing dates were May 12, 2017, and April 19, 2018, according to weather conditions.

As a result of the analysis, the electrical conductivity value (EC) of the irrigation water was determined to be 0.60 dS m−1, pH: 7.6.

Table 2

Monthly climate data during the growth period of cotton in 2017–2018 and long-term averages in Diyarbakır

|

Months |

Average temperature (°C) |

Average max. temperature (˚C) |

Monthly average rainfall (mm) |

Average relative humidity (%) |

||||||||

|

|

2017 |

2018 |

Long-term avg. |

2017 |

2018 |

Long-term avg. |

2017 |

2018 |

Long-term avg. |

2017 |

2018 |

Long-term avg. |

|

April |

12.8 |

15.9 |

13.8 |

19.5 |

24 |

20.2 |

98.8 |

48.6 |

68.7 |

68.5 |

52.9 |

63 |

|

May |

18.8 |

19.4 |

19.3 |

26.3 |

26.5 |

26.5 |

30.6 |

157.6 |

42.8 |

57.6 |

67.3 |

56 |

|

June |

26.9 |

26.6 |

26.3 |

35 |

34.5 |

33.7 |

2.6 |

14.4 |

8 |

30 |

37.4 |

31 |

|

July |

32.3 |

31.2 |

31.2 |

40.7 |

39.3 |

38.4 |

0 |

0 |

0.7 |

19.4 |

24.1 |

27 |

|

August |

31.1 |

31.4 |

30.3 |

39.9 |

39.1 |

38.1 |

0 |

0.8 |

0.4 |

22.8 |

24.1 |

28 |

|

September |

26.8 |

26.1 |

24.8 |

36.4 |

34.6 |

33.2 |

0 |

6.2 |

3.9 |

22.3 |

29.3 |

32 |

|

October |

17.2 |

18.7 |

17.2 |

24.8 |

25.8 |

25.2 |

22 |

76.6 |

31.7 |

39.2 |

52.3 |

48 |

Irrigation applications consisted of three main plots, and three subplots [df=(3−1)*(3−1)*(4−1)=12]

Main Plots: Irrigation Applications

1 – I 100 (Fully Irrigated)

2 – I 75 (25% Water Stress)

3 – I 50 (50% Water Stress)

Subplots: Cotton Varieties

1 – ST 468

2 – FM 832

3 – Kartanesi

Irrigation was performed based on the cumulative evaporation from a Class A pan for each 5-day period (Cetin and Bilgel, 2002).

The initial irrigation was applied to all treatments equally by a drip irrigation system to bring the soil water content to a 0–60 cm soil layer until the field capacity point. Irrigation was applied using the following equation (Eq. 1) (Öktem, 2006):

I = A. Ep. Kpc. P (1)

where: I is the amount of irrigation water (mm); A is the plot area (m2); Ep is the cumulative water depth from Class A pan based on irrigation frequency (mm); Kcp is the crop pan coefficient determined as 100% of total Class A Pan (I 100), 75% of total Class A Pan (I 75), 50% of total Class A Pan (I 50); and P is the wetted area ratio, which was accepted as 1. Considering the soil analyses for both years, 80 kg ha−1 (P2O5) phosphorus and 1/4 of 160 kg ha−1 pure nitrogen were applied to each plot as base fertiliser, whereas the remaining 3/4 of nitrogen was applied by fertigation until the peak flowering period (at the beginning of square – at the beginning of flowering- flowering period).

The first harvest was handpicked at 60% boll opening. All opened bolls were gathered, and the remaining cotton was collected at the second harvest time. At harvest, two rows in the middle of the plots were harvested to determine the yield. For quality parameters, samples from 50 bolls were randomly sampled separately for each treatment. The first harvest was performed on October 10, 2017, and October 1, 2018, and the second harvest occurred on November 27, 2017, and November 2, 2018. After harvesting, the ginning process was performed using a roller-gin machine. From each treatment, 50 g of fibre was used for analysis. The fibre technological characteristics of the trial were examined using an HVI 1000 (USTER Technologies, Swiss) device in the cotton fibre quality laboratory of GAPUTAEM.

Fibre analysis is affected by the environmental factors of where the samples were taken. Therefore, the conditions were provided according to quality control procedures in the laboratory, as well as the appropriate calibration of the HVI machine. The temperature (21 ± 1°C) and relative humidity (65 ± 2%) of the laboratory were set up according to ASTM D-1776 standards, while the samples’ humidity (6.75–8.25%) was arranged following ASTM D-5867 standards.

RESULTS AND DISCUSSION

Fibre Quality Measurements Fibre Micronaire (mic)

Cotton fibre fineness affects end-product quality. Micronaire is a quality parameter associated with fineness and fibre maturity (Abbas and Ahmed, 2018). The fineness of the fibres is of great importance for yarn quality, as in the case of the rotor spinning method. The application of irrigation levels caused a decrease in the fibre micronaire value in this study. Considering the results of the two-year combined analysis of variance, the fineness average values of the two years ranged between 4.13 (I 100) and 4.36 (I 50) mic. It was determined that there were significant statistical differences in application × variety interactions, and the highest fibre fineness (4.59 mic.) value was obtained from ST 468 at the I 100 level, while the lowest (3.66 mic.) value was obtained from FM 832 at the I 50 level. In the comparison of years, the fibres in 2017 were finer (3.97 mic.) than in 2018 (4.49 mic.). In that case, different sowing dates (May 12, 2017, and April 19, 2018) and total precipitation amounts should be considered. The results regarding fibre fineness (mic) were the same as in the study conducted by Karademir et al. (2011). Conversely, in some studies, a water deficit leads to strong fibre with high micronaire values (Mert, 2005).

Table 3

Average fibre micronaire (mic) of cotton varieties and statistical groups for each year and over the two years

|

Varieties |

Fibre Micronaire (micronaire) |

||||||||||||

|

2017 |

2018 |

Combined Analysis |

|||||||||||

|

I 100 |

I 75 |

I 50 |

Mean |

I 100 |

I 75 |

I 50 |

Mean |

I 100 |

I 75 |

I 50 |

Mean |

||

|

Kartanesi |

4.01 |

3.88 |

4.24 |

4.04 |

4.19 |

4.48 |

4.39 |

4.35 |

4.10 b |

4.18 b |

4.31 ab |

4.20 b |

|

|

ST 468 |

4.21 |

4.14 |

4.11 |

4.15 |

4.98 |

4.61 |

4.71 |

4.77 |

4.59 a |

4.38 ab |

4.40 ab |

4.45 a |

|

|

FM 832 |

4.20 |

3.77 |

3.13 |

3.70 |

4.57 |

4.29 |

4.19 |

4.35 |

4.38 ab |

4.03 bc |

3.66 c |

4.02 b |

|

|

Mean |

4.14 |

3.93 |

3.83 |

|

4.58 |

4.46 |

4.43 |

|

4.36 a |

4.19 ab |

4.13 b |

|

|

|

General Mean |

3.97 b |

4.49 a |

4.23 |

||||||||||

|

CV (%) |

9.00 |

||||||||||||

|

LSD (0.05) |

|

||||||||||||

|

Y. |

0.15** |

||||||||||||

|

T. |

0.17* |

||||||||||||

|

Y. x T. |

N.S. |

||||||||||||

|

V. |

0.22** |

||||||||||||

|

Y. x V. |

N.S. |

||||||||||||

|

T. x V. |

0.38* |

||||||||||||

|

Y x T x V |

N.S. |

||||||||||||

*, **, Significant at p≤0.05 and p≤0.01, respectively; N.S = Not significant, Y: Year, T: Treatment, V: Variety.

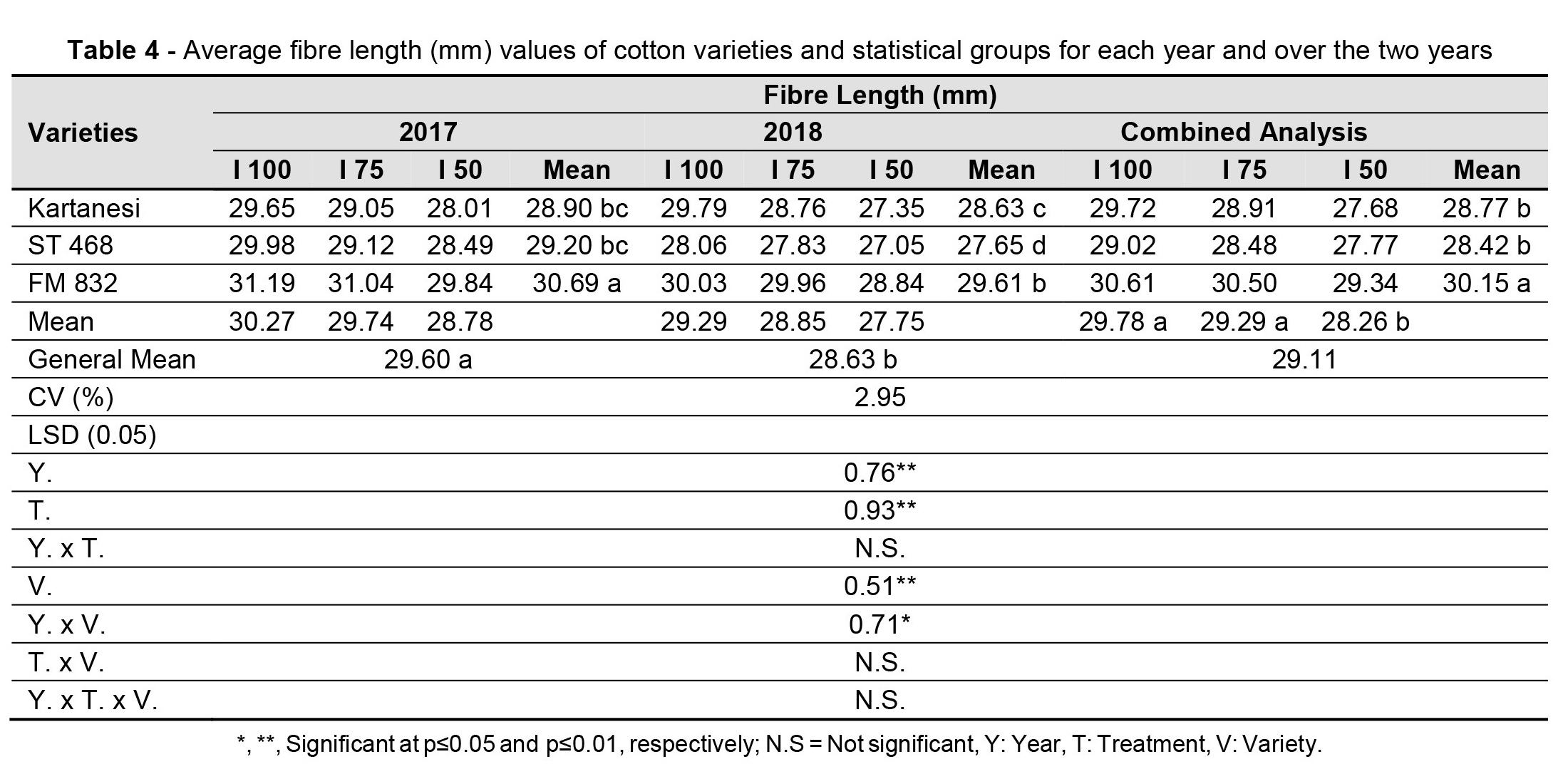

Fibre Length (mm) and Fibre Uniformity Index (%)

Fibre length values are significant for spinning performance, fineness, evenness, and especially for yarn strength. As the percentage of short fibres in cotton increases, yarn breaks increase, strength decreases, and unevenness increases during the process.

Fibre length, which is the purpose of using cotton in the textile industry, is one of the most important desired physical properties. As shown in Table 4, variety, year, irrigation application (p<0.01), and year × application interaction (p<0.05) were significant for fibre length. The plots with the I 100 irrigation treatment had the longest fibre length (29.78 mm), while I 50 had the shortest (28.26 mm).

When the study was examined in terms of varieties, FM 832 was in the first group with a value of 30.15 mm, and Kartanesi and ST 468 varieties were in the second group with values of 28.77 and 28.42 mm, respectively.

These results agree with Başal et al. (2009), Sarı and Dağdelen (2010), Karademir et al. (2011) and Nazar et al. (2012), who reported that water stress caused a decrease in fibre length.

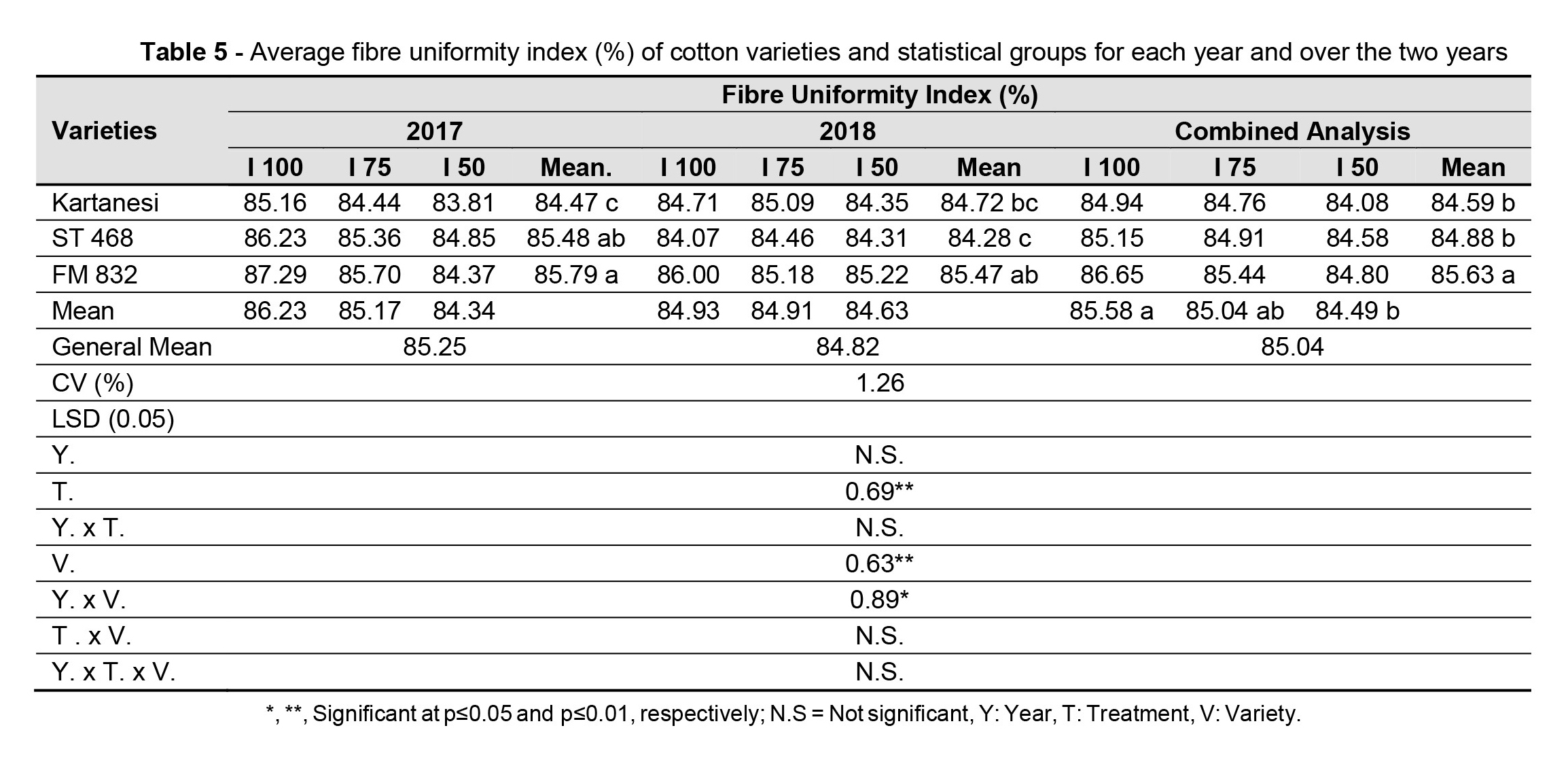

The fibre uniformity presented in Table 5 was affected by water stress. The highest fibre uniformity index value was obtained from the I 100 irrigation treatment (85.58%), while the lowest (84.49%) was obtained from the I 50 treatment. The mean uniformity index was in FM 832 (85.63%), followed by ST 468 (84.88%) and Kartanesi (84.59%).

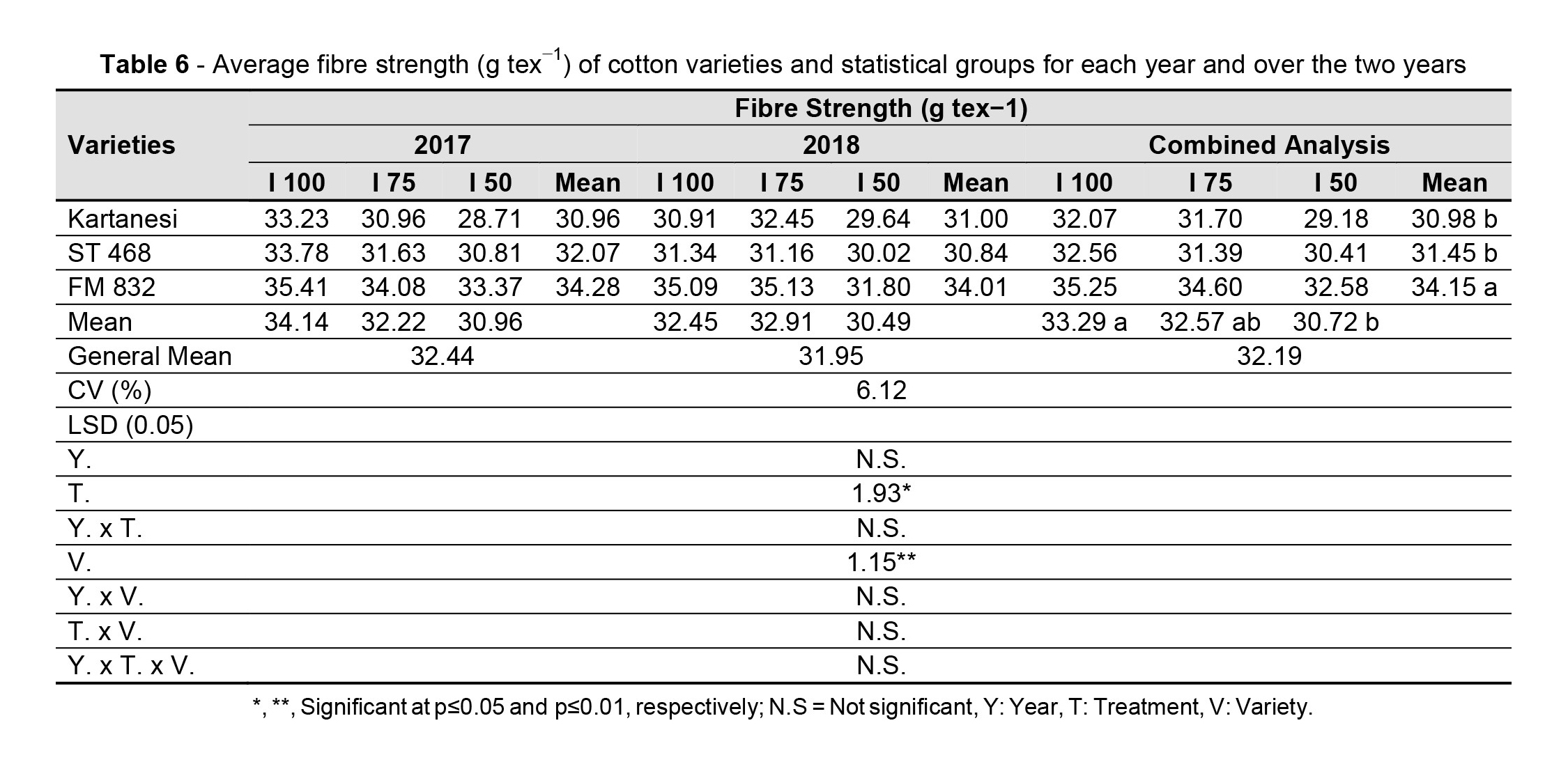

Fibre Strength (g tex−1)

Fibre strength is one of the must-have features of cotton for the end-product. Therefore, it is important for both producers, in terms of income, and traders to provide the proper material to be produced in a high-quality product.

In terms of water stress, significant differences were found among varieties and irrigation applications. The differences between years, year × application, year × variety, application × variety, and year × application × variety interactions were insignificant. As shown in Table 6, the highest value was obtained from I 100 (33.29 g tex−1), while the lowest value was acquired from the I 50 (30.72 g tex−1) water stress treatment for an average of two years.

The results obtained from the statistical data revealed that varieties differed significantly in maintaining fibre strength, and the values varied from 30.98 to 34.15 mm. FM 832 had the highest fibre strength value (34.15 g tex−1) among the varieties.

Başal et al. (2014), Karademir et al. (2015) and Wang et al. (2016) showed that water stress had a negative impact on fibre strength, which agrees with the present results.

Fibre Elongation (%)

For textile manufacturing, the degree of fibre elongation is significant. In the ginning process, it is important to have fibres that can be durable during mechanical procedures to avoid fibre breakage. This feature will allow the fibres to spin effectively (Mathangadeera et al., 2020).

Mathangadeera et al. (2020) stated that fibres that have low elongation values break more constantly. I 100 and I 75 irrigation treatments took part in the same group, with values of 5.50% and 5.47%, respectively, and I 50 (5.28%) was in the second group in terms of statistical significance. From this point of view, 25% water stress did not negatively affect fibre elongation.

Considering Table 7, among the varieties, ST 468 had the highest fibre elongation value (5.73%).

The differences between the years were statistically significant. The elongation value in 2018 (5.61%) was higher than in 2017 (5.23%). The difference between years may occur due to different climatic conditions.

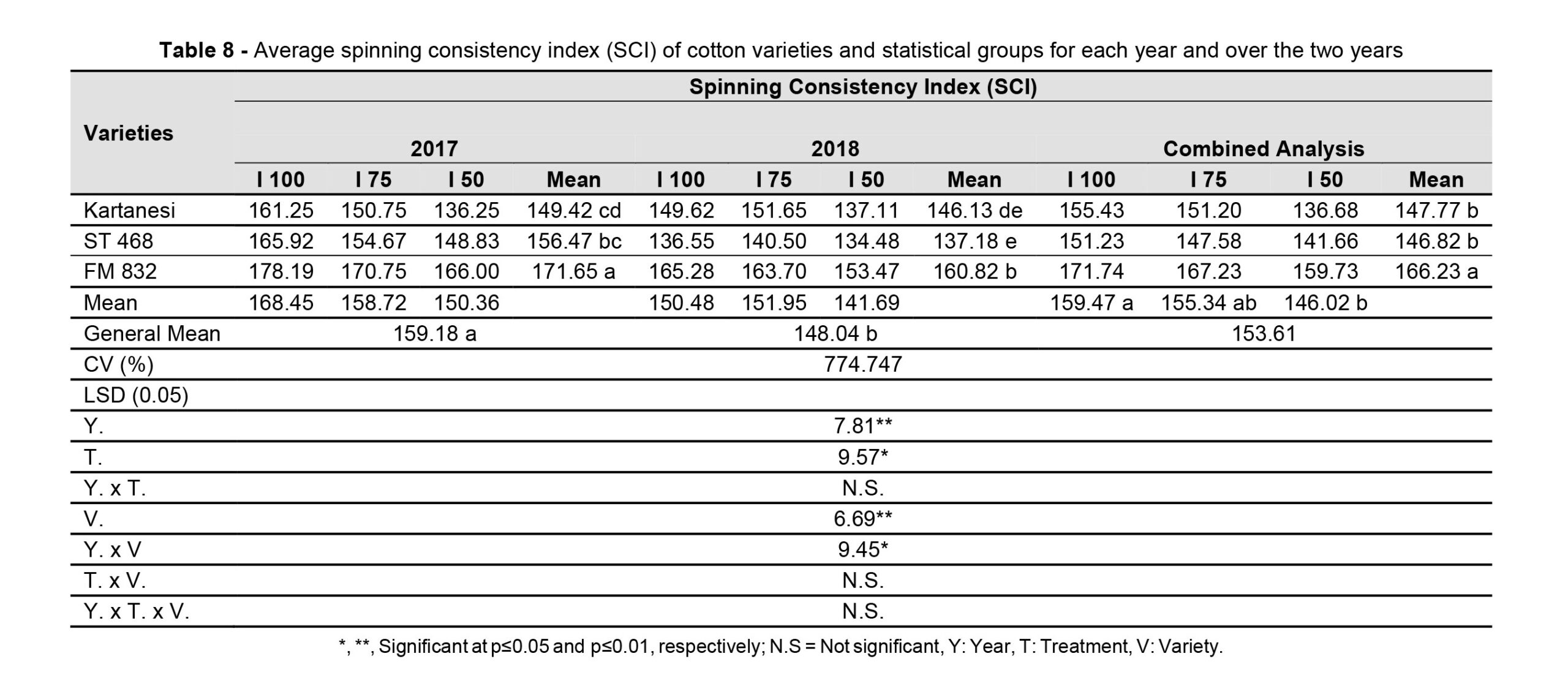

Spinning Consistency Index (SCI)

The spinning consistency index (SCI) is a criterion used to calculate the spinnability of fibres, as well as to determine the yarn fibre strength and spinning potential. Regarding the textile industry, high spinnability stands for better fibre quality in cotton.

As shown in Table 8, SCI values were affected by water stress treatments and ranged between 159.47% (I 100) and 146.02% (I 50). In this study, different irrigation levels were effective on the spinning consistency index in both study years. In terms of the mean values of the varieties, the highest SCI (166.23%) was achieved by FM 832

Short Fibre Index (SF%)

Low short fibre content is a desired parameter for the textile industry. In this study, different irrigation levels influenced short fibre content in both growing seasons (2017 and 2018). The minimum short fibre content was obtained in 2018 (5.70%). The results showed that water deficiency increased the short fibre content, as shown in Table 9.

Table 7

Average fibre elongation (%) of cotton varieties and statistical groups for each year and over the two years

|

Varieties |

Fibre Elongation (%) |

|||||||||||

|

2017 |

2018 |

Combined Analysis |

||||||||||

|

I 100 |

I 75 |

I 50 |

Mean |

I 100 |

I 75 |

I 50 |

Mean |

I 100 |

I 75 |

I 50 |

Mean |

|

|

Kartanesi |

5.25 |

5.50 |

5.06 |

5.27 |

5.92 |

5.60 |

5.62 |

5.71 |

5.58 |

5.55 |

5.34 |

5.49 b |

|

ST 468 |

5.72 |

5.57 |

5.49 |

5.59 |

5.92 |

5.85 |

5.84 |

5.87 |

5.82 |

5.71 |

5.67 |

5.73 a |

|

FM 832 |

5.02 |

4.87 |

4.60 |

4.83 |

5.18 |

5.43 |

5.09 |

5.24 |

5.10 |

5.15 |

4.85 |

5.03 c |

|

Mean |

5.33 |

5.31 |

5.05 |

|

5.68 |

5.63 |

5.52 |

|

5.50 a |

5.47 a |

5.28 b |

|

|

General Mean |

5.23 b |

5.61 a |

5.42 |

|

||||||||

|

CV (%) |

4.62 |

|||||||||||

|

LSD (0.05) |

|

|||||||||||

|

Y. |

0.13** |

|||||||||||

|

T. |

0.15* |

|||||||||||

|

Y. x T. |

N.S. |

|||||||||||

|

V. |

0.14** |

|||||||||||

|

Y. x V. |

N.S. |

|||||||||||

|

T. x V. |

N.S. |

|||||||||||

|

Y. x T. x V. |

N.S. |

|||||||||||

*, **, Significant at p≤0.05 and p≤0.01, respectively; N.S = Not significant, Y: Year, T: Treatment, V: Variety.

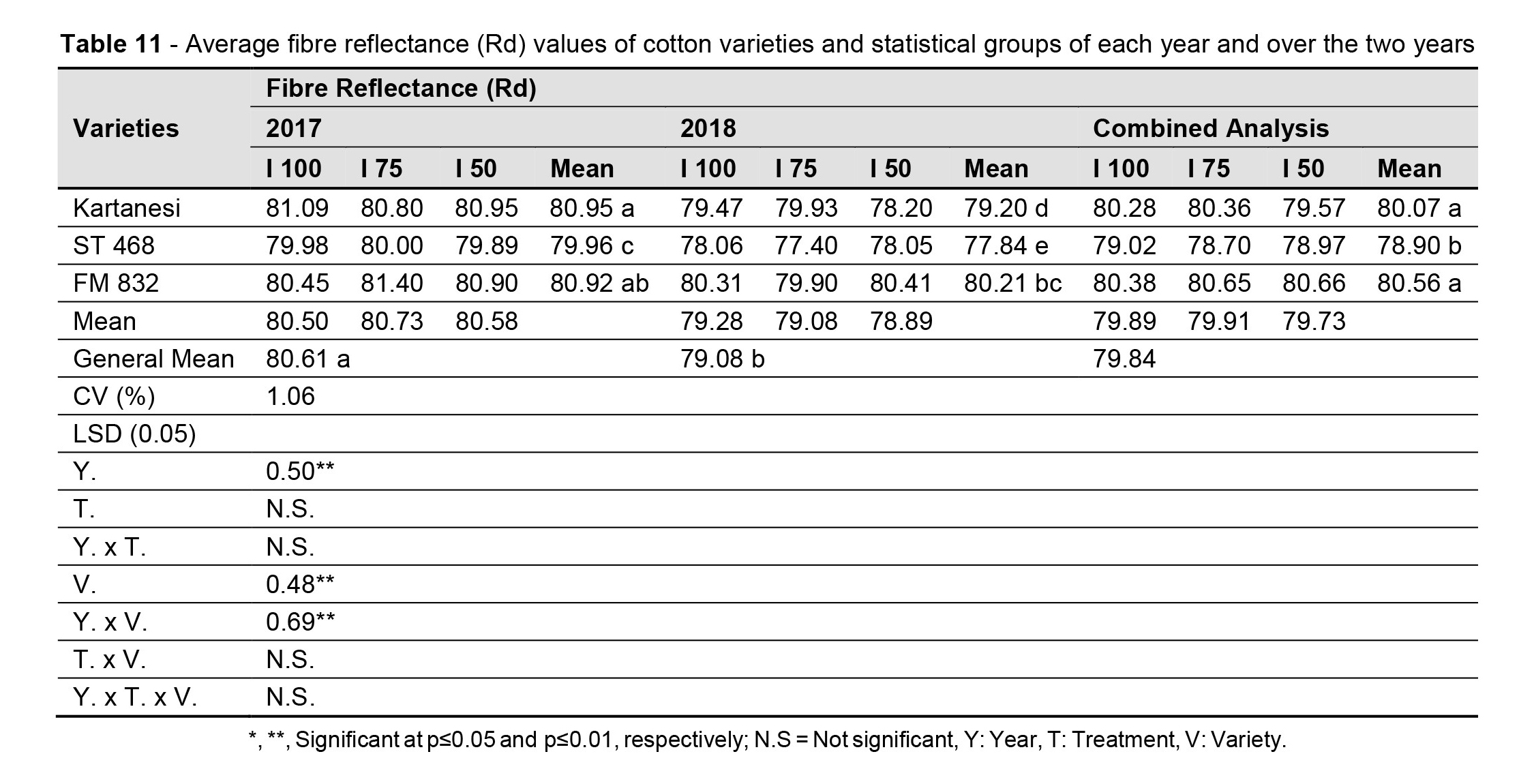

Fibre Yellowness and Reflectance (Rd)

Fibre colour is a basic criterion of cotton classification into cotton grades according to the Universal Cotton Standards (UCS). The grade is regulated by two parameters, reflectance (Rd) and yellowness (+b), with the use of HVI. While yellowness is related to cotton pigmentation, reflectance is associated with the brightness of cotton, which is a parameter significant to cotton pricing. Cotton colour helps to absorb and hold the dyes in the end-product; therefore, the process efficiency depends on these two parameters (Mathangadeera et al., 2020).

Data based on Table 10 reveal that decreasing irrigation levels leads to significantly increased fibre yellowness values. The highest fibre yellowness value was obtained from the I 50 treatment. Although there was no significant difference between the years, the lowest fibre yellowness (7.88) was obtained in the FM 832 variety.

For fibre reflectance, considerable differences were observed among varieties and years. Considering Table 11, the fibre reflectance values ranged between 78.90 and 80.56 Rd, and the maximum fibre reflectance was obtained from the FM 832 variety. While brightness (Rd) affects colour grade positively, yellowness (+b) is an undesirable feature.

Fibre reflectance was not affected by irrigation applications. In this respect, our findings differ from those of Ertek and Kanber (2002), who stated that brightness value increased in the infrequent irrigation range and at higher irrigation levels in the drip irrigation system

Table 9

Average short fibre content (%) of cotton varieties and statistical groups for each year and over the two years

|

Varieties |

Short Fibre Index (SF%) |

|||||||||||

|

2017 |

2018 |

Combined Analysis |

||||||||||

|

I 100 |

I 75 |

I 50 |

Ort. |

I 100 |

I 75 |

I 50 |

Mean |

I 100 |

I 75 |

I 50 |

Mean |

|

|

Kartanesi |

6.64 |

7.29 |

8.06 |

7.33 |

5.15 |

5.95 |

6.10 |

5.73 |

5.89 |

6.62 |

7.08 |

6.53 |

|

ST 468 |

5.93 |

6.44 |

7.11 |

6.49 |

5.98 |

6.14 |

5.76 |

5.96 |

5.96 |

6.29 |

6.44 |

6.23 |

|

FM 832 |

5.80 |

6.67 |

7.83 |

6.77 |

4.67 |

5.18 |

6.37 |

5.40 |

5.23 |

5.92 |

7.10 |

6.09 |

|

Mean |

6.12 |

6.80 |

7.67 |

|

5.27 |

5.76 |

6.08 |

|

5.69 c |

6.28 b |

6.87 a |

|

|

General Mean |

6.86 a |

5.70 b |

6.28 |

|||||||||

|

CV (%) |

14.81 |

|||||||||||

|

LSD (0.05) |

|

|||||||||||

|

Y. |

0.43** |

|||||||||||

|

T. |

0.52** |

|||||||||||

|

Y. x T. |

N.S. |

|||||||||||

|

V. |

N.S. |

|||||||||||

|

Y. x V. |

N.S. |

|||||||||||

|

T. x V. |

N.S. |

|||||||||||

|

Y. x T. x V. |

N.S. |

|||||||||||

*, **, Significant at p≤0.05 and p≤0.01, respectively; N.S = Not significant, Y: Year, T: Treatment, V: Variety.

Table 10

Average fibre yellowness values of cotton varieties and statistical groups for each year and over the two years

|

Varieties |

Fibre Yellowness Value (+b) |

|||||||||||

|

2017 |

2018 |

Combined Analysis |

||||||||||

|

I 100 |

I 75 |

I 50 |

Mean |

I 100 |

I 75 |

I 50 |

Mean |

I 100 |

I 75 |

I 50 |

Mean |

|

|

Kartanesi |

8.38 |

8.22 |

8.48 |

8.36 |

7.96 |

8.27 |

8.62 |

8.28 |

8.17 |

8.24 |

8.55 |

8.32 b |

|

ST 468 |

8.60 |

9.04 |

8.84 |

8.83 |

8.81 |

9.07 |

9.11 |

9.00 |

8.71 |

9.06 |

8.98 |

8.91 a |

|

FM 832 |

8.00 |

7.73 |

8.03 |

7.92 |

7.77 |

7.71 |

8.02 |

7.83 |

7.88 |

7.72 |

8.03 |

7.88 c |

|

Mean |

8.33 |

8.33 |

8.45 |

|

8.18 |

8.35 |

8.58 |

|

8.25 b |

8.34 ab |

8.52 a |

|

|

General Mean |

8.36 |

8.37 |

8.37 |

|||||||||

|

CV (%) |

4.78 |

|||||||||||

|

LSD (0.05) |

|

|||||||||||

|

Y. |

N.S. |

|||||||||||

|

T. |

0.20* |

|||||||||||

|

Y. x T. |

N.S. |

|||||||||||

|

V. |

0.22** |

|||||||||||

|

Y. x V. |

N.S. |

|||||||||||

|

T. x V. |

N.S. |

|||||||||||

|

Y. x T. x V. |

N.S. |

|||||||||||

*, **, Significant at p≤0.05 and p≤0.01, respectively; N.S = Not significant, Y: Year, T: Treatment, V: Variety.

CONCLUSION

The results from this study indicated that water stress significantly affected fibre quality properties, except for fibre reflectance, and it has been observed that this effect leads to more significant reductions in the 50% water stress level.

While FM 832 performed well under water stress conditions in terms of fineness, length, strength, uniformity, yellowness, reflectance, and spinning consistency index, ST 468 came to the fore due to its fibre elongation value. FM 832 with I 75 irrigation treatment is recommended for fibre quality studies.

Funding: That trial was financially supported by the Republic of Turkiye, the Ministry of Agriculture and Forestry, TAGEM (General Directorate of Agricultural Research and Policies) with TAGEM/TBAD/A/18/A7/P5/192 project number and also funded by the Scientific Research Projects Coordination Unit of Siirt University with the project number 2017-SIUFEB-DR-25.

REFERENCES

Abbas, Q.; Ahmad, S. Effect of Different Sowing Times and Cultivars on Cotton Fiber Quality under Stable Cotton-Wheat Cropping System in Southern Punjab, Pakistan. Pakistan Journal of Life & Social Sciences. 2018, 16(2), 77-84.

Başal, H.; Dagdelen, N.; Unay, A.; Yilmaz, E. Effects of deficit drip irrigation ratios on cotton (Gossypium hirsutum L.) yield and fiber quality. Journal of Agronomy and Crop Science. 2009, 195(1), 19-29. https://doi.org/10.1111/j.1439-037X.2008.00340.x.

Başal, H.; Sezener, V.; Canavar, O.; Kızılkaya, K.; Dagdelen, N. Effects of water stress and plant density on cotton (Gossypium hirsutum L.) cultivars differing in maturity and seed size: I. Yield components and fiber quality parameters. International Journal of Agriculture Innovations Research. 2014, 3(3), 755-760.

Bradow, J.M.; Davidonis, G.H. Effects of environment on fiber quality, In Physiology of Cotton. Springer (ed.). Netherlands, 2010, 229–245. https://doi.org/10.1007/978-90-481-3195-2_21.

Cetin, O.; Bilgel, L. Effects of different irrigation methods on shedding and yield of cotton. Agricultural Water Management. 2002, 54(1), 1-15. https://doi.org/10.1016/S0378-3774(01)00138-X.

Ertek, A.; Kanber, R. The effects of the drip irrigation method on the salt distribution in the soil in cotton irrigation (in Turkish). Journal of Agricultural Sciences University Yüzüncü Yıl. 2002, 12(2), 21-31.

Gürsoy, S.; Kılıç, H.; Sessiz, A. Determination of the most appropriate seedbed preparation and sowing method after cotton harvest in the cotton-wheat rotation system in the Southeastern Anatolia Region (in Turkish). TAGEM Result Report, Diyarbakır.

ICAC, (International Cotton Advisory Committee). 2022. https://www.cottonportal.org/cotton/en/cotton-content/cotton-statistics (accessed on 13 October 2022).

Karademir, Ç.; Karademir, E.; Ekinci, R.; Berekatoğlu, K. Yield and fiber quality properties of cotton (Gossypium hirsutum L.) under water stress and non-stress conditions. African Journal of Biotechnology. 2011, 10(59), 12575-12583. https://doi.org/10.5897/AJB11.1118

Karademir, E.; Karademir, Ç.; Ekinci, R.; Sevilmiș, U. Determination of yield and fiber quality properties in advanced generation lines in cotton (Gossypium hirsutum L.) (in Turkish). Turkish Journal of Agricultural Studies. 2015, 2(2), 100-107.

Khanzada, H.; Khan, M.Q.; Kayani, S. Cotton based clothing. In Cotton science and processing technology. Springer, Singapore, 2020, 377-391.

Mathangadeera, R.W.; Hequet, E.F.; Kelly, B.; Dever, J.K.; Kelly, C.M. Importance of cotton fiber elongation in fiber processing. Industrial Crops and Products. 2020, 147, 112217. https://doi.org/10.1016/j.indcrop.2020.112217

Mert, M. Irrigation of cotton cultivars improves seed cotton yield, yield components, and fiber properties in the Hatay region, Turkey. Acta Agriculturae Scandinavica, Section B-Soil & Plant Science. 2005, 55(1), 44-50. https://doi.org/10.1080/09064710510008658

Nazar, A.; Iftikhar, M.; Shahbaz, B.; Ishaq, W. Influence of irrigation water types and stress levels on cotton fiber and yarn quality for different varieties. Pakistan Journal of Agricultural Sciences. 2012, 49(4), 597-601.

Orta, A.H.; Erdem, T.; Erdem, Y.; Cinkılıç, L. Planning the Irrigation Time of the Tomato Plant Irrigated by Drip Method in Greenhouse Conditions (in Turkish). Ulusal Kültürteknik Kongresi Bild. Bursa. 1997.

Öktem, A. Effect of different irrigation intervals to drip irrigated dent corn (Zea mays L. indentata) water-yield relationship. Pakistan Journal of Biological Sciences. 2006, 9(8), 1476-1481.

Pettigrew, W.T. Moisture deficit effects on cotton lint yield, yield components, and boll distribution. Agronomy Journal. 2004, 96(2), 377-383. https://doi.org/ 10.2134/agronj2004.0377.

Rehman, A.; Azhar, M.T. Genetic assessment of chlorophyll A and B, carotenoids and stomatal conductance in leaf tissue of upland cotton in water stress conditions. Journal of Animal & Plant Sciences. 2021, 31(1).

Rehman, A.; Azhar, M.T.; Shakeel, A.; Basra, S.M.A. Breeding potential of upland cotton for water stress tolerance. Pakistan Journal of Agricultural Sciences. 2017, 54(3).

Sarı, Ö.; Dağdelen, N. The effect of different laterality on cotton water-yield relationships in cotton irrigated by drip irrigation method. 2010.

Snowden, M.C.; Ritchie, G.L.; Simao, F.R.; Bordovsky, J.P. The timing of episodic drought can be critical in cotton. Agronomy Journal. 2014, 106(2), 452-458. https://doi.org/10.2134/agronj20 13.0325.

Tunalı, S. P.; Gürbüz, T.; Akçay, S.; Dağdelen, N. The Effects of Water Stress on Yield Components and Fiber Quality Traits in Cotton Varieties in Aydın Conditions. Etkileri (in Turkish). Journal of ÇOMÜ Faculty of Agriculture. 2013, 7(1), 161-168.

Uster. Uster HVI 1000 Application Handbook, USTER Technologies AG,Switzerland,2-1,29. https://csitc.org/sitecontent/RTCEA/internal_ea/02_RTC_Content/022_Training/0222_Training_documents/02225_USTER/USTER%20HVI%20Instrruction/0222523_MILL_H VI1000_INSTR_01210.pdf.

Wang, Y.; Liang, C.; Wu, S.; Zhang, X.; Tang, J.; Jian, G. et al. Significant improvement of cotton Verticillium wilt resistance by manipulating the expression of Gastrodia antifungal proteins. Molecular plant. 2016, 9(10), 1436-1439.

Academic Editor: Dr. Isabela Simion

Publisher Note: Regarding jurisdictional assertions in published maps and institutional affiliations ALSE maintain neutrality.