Laurențiu Adam, Dorina-Nicolina Isopescu

ABSTRACT. Food, energy and construction are the three main domains in which different uses of industrial hemp confirm the role and importance that agriculture has in human life. In the current context with an increased need for energy efficiency and environmental protection, the attention of scientists is directed towards the identification of ecological construction materials, and a sustainable way of life, where the circular economy must become part of people’s living habits. The objective of the research was to analyze the thermo-mechanical properties of hempcrete. The goal is to determine a point of reference for future studies that will aim to adapt the agreed compositions to the particularities of the raw material obtained locally. Measurements were determined through laboratory tests, performed on specimens obtained using, for the base material, the woody part of industrial hemp, and for the binder, a mixture consisting of hydrated lime and Portland cement. The results place the construction materials made from hemp vegetable waste in the group of heat-insulating products characterized by low specific weight and thermal transfer coefficients, according with conventional insulating materials, with values between those of polyurethane foam and autoclaved cellular concrete.

Keywords: eco hempcrete; natural composite materials; circular economy; vegetable waste.

Cite

ALSE and ACS Style

Adam, L.; Isopescu, D.-N. Physico-mechanical properties investigation of hempcrete. Journal of Applied Life Sciences and Environment 2022, 55(1), 75-84.

https://doi.org/10.46909/alse-551047

AMA Style

Adam L, Isopescu D-N. Physico-mechanical properties investigation of hempcrete. Journal of Applied Life Sciences and Environment. 2022; 55(1): 75-84.

https://doi.org/10.46909/alse-551047

Chicago/Turabian Style

Adam, Laurențiu, and Dorina-Nicolina Isopescu. 2022. “Physico-mechanical properties investigation of hempcrete” Journal of Applied Life Sciences and Environment 55, no. 1: 75-84.

https://doi.org/10.46909/alse-551047

View full article (HTML)

Physico-Mechanical Properties Investigation of Hempcrete

Laurențiu ADAM* and Dorina-Nicolina ISOPESCU

“Gheorghe Asachi” Technical University of Iasi, Faculty of Civil Engineering and Building Services, Bd. D. Mangeron 67, Iași 700050, Romania; email: dorina-nicolina.isopescu@academic.tuiasi.ro

*Correspondence: laurentiu.adam@student.tuiasi.ro

Received: Oct. 12, 2022. Revised: Nov. 7, 2022. Accepted: Nov. 16, 2022. Published online: Nov. 24, 2022

ABSTRACT. Food, energy and construction are the three main domains in which different uses of industrial hemp confirm the role and importance that agriculture has in human life. In the current context with an increased need for energy efficiency and environmental protection, the attention of scientists is directed towards the identification of ecological construction materials, and a sustainable way of life, where the circular economy must become part of people’s living habits. The objective of the research was to analyze the thermo-mechanical properties of hempcrete. The goal is to determine a point of reference for future studies that will aim to adapt the agreed compositions to the particularities of the raw material obtained locally. Measurements were determined through laboratory tests, performed on specimens obtained using, for the base material, the woody part of industrial hemp, and for the binder, a mixture consisting of hydrated lime and Portland cement. The results place the construction materials made from hemp vegetable waste in the group of heat-insulating products characterized by low specific weight and thermal transfer coefficients, according with conventional insulating materials, with values between those of polyurethane foam and autoclaved cellular concrete.

Keywords: eco hempcrete; natural composite materials; circular economy; vegetable waste.

INTRODUCTION

A large amount of energy is currently used to obtain indoor thermal comfort in residential buildings, where an energy consumption of almost 25% of the total global energy demand is recorded for cooling and heating interior spaces (Ingrao et al., 2015). It is estimated that, together with this energy used, a quantity of approximately one-third of the total CO2 emissions is also released into the atmosphere (Abdellatef and Kavgic, 2020).

Not only the energy consumption required during the operation and maintenance of the building is important, but also the amount of energy used for the construction industry, including the energy used for obtaining the raw material necessary for the production of the construction materials and their assembly in new buildings. Researchers’ attention is being directed towards the innovation of environmentally friendly construction materials. The goal is to replace the conventional construction materials with a bio-based material that can achieve the same hygro-thermal comfort for occupants, but with a lower energy consumption (Faiz Ahmed et al., 2022). Such a construction material is represented by lightweight concrete based on hemp wood chips named hemp-lime-concrete composite or hempcrete, which is a building material made from lime-based binder and biodegradable vegetable waste with particle sizes between zero and 5 cm, obtained from industrial hemp rods after the decortication process. This is a manual or automated technological process in which the lignified stem of industrial hemp cannabis sativa is separated into textile fibres and pieces of wood after passing through a device that bends the stems to break them. The fiber then detaches from the woody part of the stem. The fibers that surround the stem are flexible and resistant, which allows them to remain intact, while the brittle woody stem, under the fiber, breaks. Following successive and frequent bends made transversely along the length of the stems, the fiber detaches from the woody part as a result of the sliding that takes place at the separation surface between the two morphological parts that make up the stems. The goal is to obtain two materials from a single crop that have different uses so that the plant can be fully exploited, making hemp culture profitable (Tronet et al., 2016). Notable uses of hempcrete started in early 1986 when the bricklayer Charles Rasetti from the north of France used for the first time this bio-based material to refurbish the walls of the Maison de la Turque (Perletti, 2020). For the production of hempcrete, the basic recipe contains the following elements: hemp wood chips, mineral binders and water. For the mineral binders mixtures of cement and hydrated lime with different mass ratios were used (Colinart et al., 2012). Hempcrete is considered to be an eco-sustainable building material because, during the slow hardening process, the lime absorbs CO2 from the atmosphere. Slow hardening has been a disadvantage that has now been solved by adding natural hydraulic lime binders into the mixture to shorten the curing time (Arehart, 2020). Hempcrete is a lightweight building material with a specific mass under 1000 kilograms per cubic meter (Antonov et al., 2017) and because of its thermo-acoustic performance (Delhomme et al., 2020; Antonov et al., 2017) hempcrete can be used to create partition or enclosing walls, insulation and base layers for floors, or as an insulating material for ceilings and roofs (Colinart et al., 2012). As construction options, the following technologies are possible: casting in situ in lost formwork, making prefabricated panels, industrial manufacture of masonry blocks (Faiz Ahmed et al., 2022; Arehart, 2020) or used as a filling material applied by spraying with the help of automated air compressed devices. There is also the possibility of making molded construction elements with the help of 3D printers (Arrigoni et al., 2017). The binder type, aggregates-to-binder ratio, level of compaction, size of the aggregates and the water-to-binder ratio all influence the properties of this porous bio-composite material (Delhomme et al., 2020). Because of its low density, the compressive strength is lower than 1 MPa (Dartois et al., 2017; Page et al., 2017) and it can be used only for non-load-bearing walls.

In the case of buildings, the energy efficiency is given by the hygro-thermal performance of the construction materials used. The loss of heat through the structural and non-structural elements of the building is influenced by the ability of the materials to transmit heat through conductivity (Collet and Pretot, 2014). In particular, and referring only to hempcrete construction materials, both in the case of the present work and in the case of other studies, in order to obtain an insulating construction material, the density must be as low as possible but meet the minimum values for mechanical resistance so that the product complies with legal regulations in the field of construction. This heat-insulating performance can be obtained by making hempcrete construction elements in the structure of which the air voids are as many and as evenly distributed as possible. Some studies show the heat transfer coefficient of the hempcrete to have values between 0.06 and 0.19 W/m x K° (Tronet et al., 2016; Constantine et al., 2018). The purpose of the work presented in the following is to make hemp samples using locally obtained industrial hemp and to determine through laboratory testing a starting point for improving the insulating characteristics of ecological building materials based on hemp. The work shows the properties of a hempcrete material made from the Zenit variety of industrial hemp cannabis sativa that is cultivated in Romania for seeds. To be energy-efficient, it is important to be able to produce and consume locally, but adopting an external recipe and simply replacing hemp shreds with the same amount of hemp but obtained in Romania does not guarantee obtaining the same performance as in the case of foreign studies.

There are a multitude of hemp varieties used on a large scale, some of them being specialized for seed production, like the Zenit variety, or fiber production like the Dacia-Secuieni variety, and there are also variants for the production of wood pulp for energy purposes, like the Ratza variety. So, some of them have more developed stems than others. This development brings changes in terms of the tensile strength, bending strength or compression strength of the woody part of the hemp stem because of the different contents of lignin, hemicellulose and cellulose. The natural porosity of the material differs from one type to another and hence the performance as a thermal insulator also differs. That is why the morphological differences between the varieties of hemp and the pedo-climatic conditions available during the growing period, as well as the zoning of the crop, can determine other types of structures in the mature plant. In the same way, the amount of fertilizer and the level of carbon dioxide available in the atmosphere in the crop area must also be analyzed, as well as the water regime and the alternation of dry and rainy periods, in order to identify the possible variations in the thermo-mechanical characteristics of the construction materials made from hemp.

MATERIALS AND METHODS

Hempcrete is a material widely used outside the country, but in Romania it is only at the beginning of the road. That is why a hempcrete recipe was taken from the Green Home Institute in the United States, where they use the hempcrete to make walls, floors or ceiling and roof insulation. The recipe is widely used in workshops, where students are taught how to measure the quantities, how to make the mixture to get the best results and how to put this ecological material into place.

The base recipe used for pouring the specimens is according to the Green Home Institute (Green Home Institute, 2017). The recipe presented in Table 1 is large-scale and used to make walls.

The percentages of materials used in the recipe are comparable to the recipe used by Evrard (Evrard, 2003) according to Bruijn (de Bruijn, 2008) as shown in Table 2.

To reduce the time required for hardening the concrete, according to Sivasubramanian (Sivasubramanian, 2019), sodium silicate – Na2SiO3 – was added in a percentage of 3% of the total water quantity used for setting the mix. After a few tests to make the mixture, the amount of water was increased and the recipe adjusted as shown in Table 3.

Table 1

Base recipe according to Green Home Institute

|

Material type |

Unit |

Quantity |

Percent % |

|

Hemp shive |

Kg |

1 |

25 |

|

Hydrated lime |

Kg |

0.75 |

18.75 |

|

Portland Cement |

Kg |

0.75 |

18.75 |

|

Water |

Kg |

1.5 |

37.5 |

|

Total |

Kg |

4 |

100 |

Table 2

Recipe used by Evrard in 2003

|

Material type |

Percent % |

|

Hemp shive |

19 |

|

Lime binder |

31 |

|

Water |

50 |

|

Total |

100 |

Table 3

Recipe used for casting the test specimens

|

Material type |

Unit |

Quan- tity |

Percent % |

|

Hemp wood Zenit variety |

kg |

1 |

23.5 |

|

Hydrated lime Super Calco |

kg |

0.75 |

17.65 |

|

Cement CEM II/A 42.5R |

kg |

0.75 |

17.65 |

|

Water |

kg |

1.7 |

40 |

|

Sodium silicate Na2SiO3 |

kg |

0.051 |

1.2 |

|

Total |

kg |

4.251 |

100 |

Another recipe used on a large scale in different types of construction is 4 parts hemp shive, 1 part lime binder and 1 part water by volume. If we make the transformation from mass to volume for the recipe presented in Table 3, the result is the ratio by volume given in Table 4.

Table 4

Quantities measured with volume recipient in test laboratory

|

Material type |

Parts by volume |

|

Hemp shive |

10 parts |

|

Lime binder |

1 part |

|

Water |

1 part |

|

Total |

12 parts |

This ratio is not the same and it is not comparable with 4:1:1. The bulk density of hemp shive used in this test is lower than the density of hemp shive used in foreign studies. This finding may generate sufficient interest in future studies to analyze different varieties of hemp in order to identify their physical properties and to demonstrate if they influence the thermo-mechanical properties of the hempcrete.

Using the proportions shown in Table 3, the quantities were measured to ensure the necessary volume for casting 9 cubes with sides of 150 × 150 mm (Figure 1).

For setting the mixture, first 3.3 kg of hemp shiv was measured and poured into a recipient. Second, 2.475 kg of hydrated lime and 2.475 kg of cement were premixed together and added to the hemp shive. The last step was to measure 5.61 kg of water and premix it with 0.168 kg of sodium silicate. All the quantities used are presented in Table 5.

Steps for setting the mixture were as follows:

- add hemp shiv to a PVC recipient,

- add lime and cement binder premixed,

- mix hemp and binder together,

- add water and sodium silicate,

- mix until all the materials become hydrated.

RESULTS

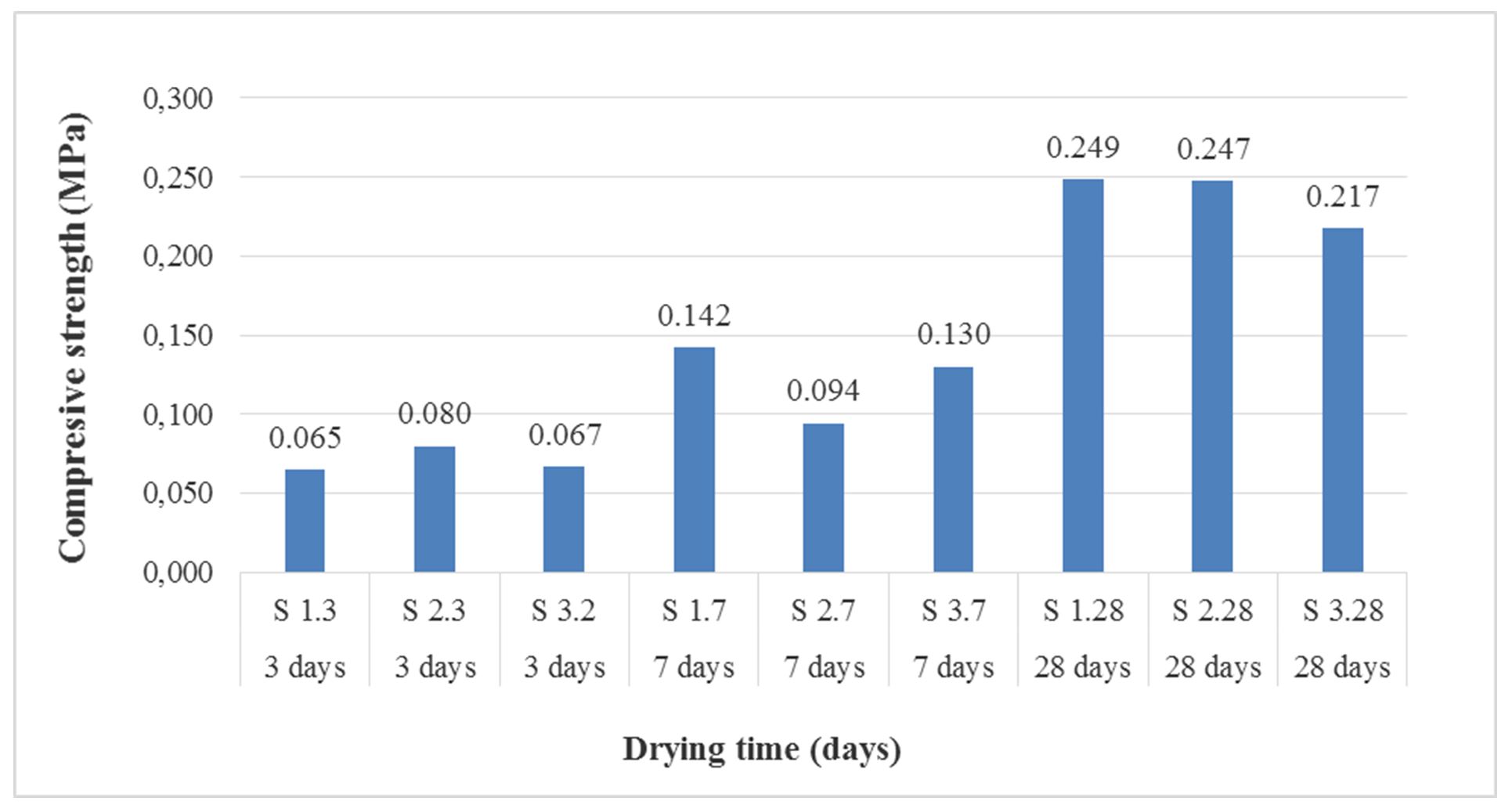

A set of three samples were tested after 3 days, another set of three samples were tested at 7 days, and at 28 days the last set of three samples were tested after drying to determine the compressive strength, as presented in Figure 2.

The values obtained after the determinations are summarized in the graph presented in Figure 3.

Figure 1 – The cubic samples

Table 5

Recipe used for pouring the 9 cubes

|

Material type |

Unit |

Quantity |

Percent % |

|

Hemp woody part – Zenit variety (0-4.5cm) |

kg |

3.3 |

23.5 |

|

Hydrated lime Super Calco |

kg |

2.475 |

17.65 |

|

Cement CEM II/A 42.5R |

kg |

2.475 |

17.65 |

|

Water |

kg |

5.61 |

40 |

|

Sodium silicate Na2SiO3 |

kg |

0.168 |

1.2 |

|

Total mass of the mixture |

kg |

14.028 |

100 |

Hemp-concrete can be used to create partition or enclosing walls only if the mechanical strength is over the limit of 0.3 MPa, which is the minimum value for self-supporting construction materials. Other options to use hempcrete are as insulation and the base layer for floors, or as an insulating material for ceilings and roofs.

Hempcrete can be used only for non-load-bearing construction elements due to its low mechanical strength.

The average values of the mechanical resistance obtained on the samples tested 3 days after casting is 0.071 MPa and on the samples tested at 7 days is 0.122 MPa. Then, 28 days after casting, the average values of the mechanical resistance obtained after testing the samples is 0.238 MPa. These are all below 0.3 MPa, the standard certification limit for self-supporting construction materials. In order to obtain a higher mechanical resistance, the lime-cement ratio must be changed.

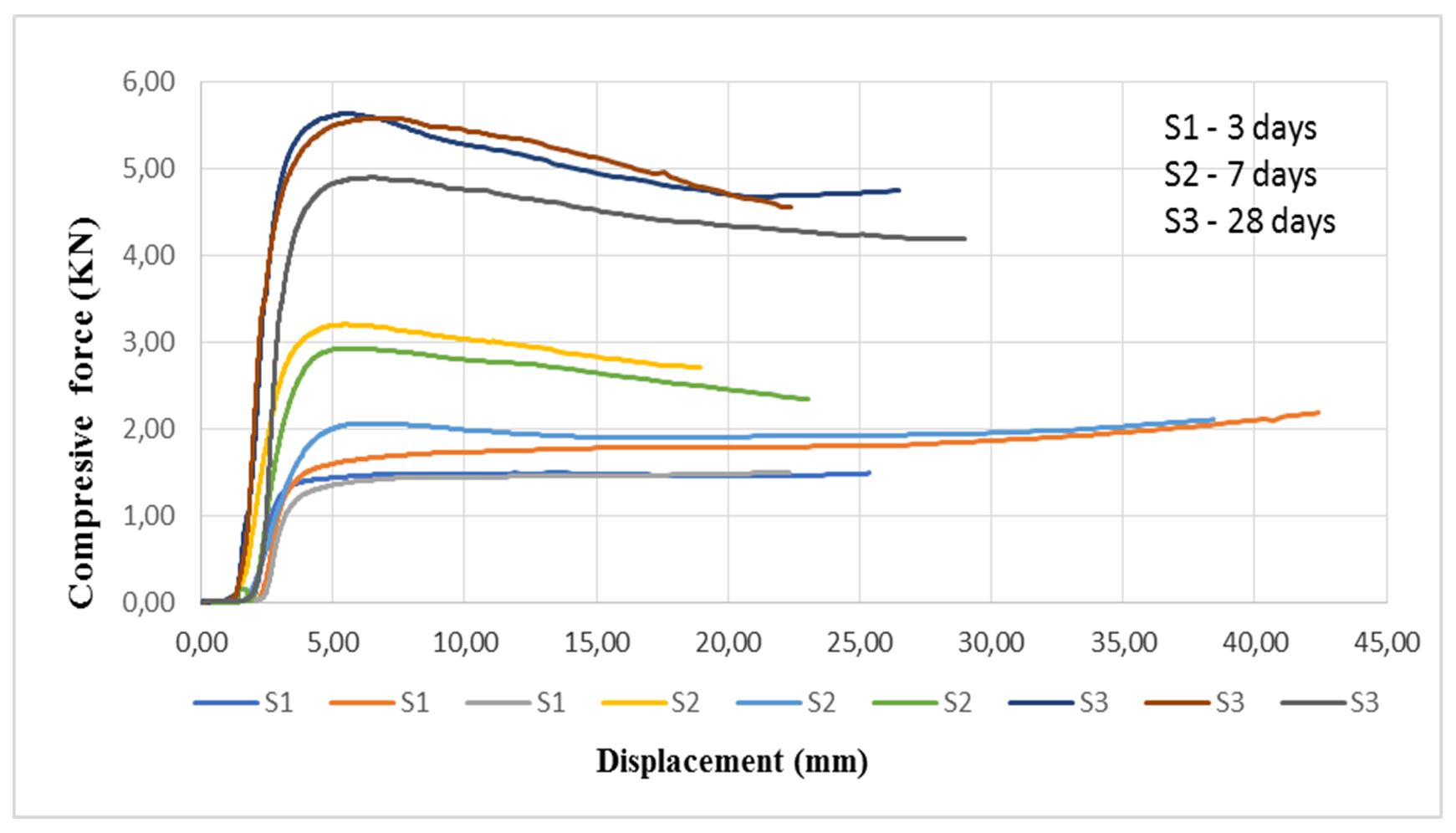

Analyzing the characteristic curve of the mechanical resistance at 3, 7 and 28 days as presented in Figure 4, a significant evolution and a behavior similar to concrete construction materials can be observed.

The material gains mechanical strength during the drying period, showing that the use of cement mixed with hydrated lime in a ratio of 1:1 increases the initial strength from an average of 0.071 MPa at 3 days to a maximum of 0.238 MPa after 28 days, which offers the possibility of putting the material into work much more quickly and enables the optimization of the execution time. Each set of 3 characteristic curves, highlighted in red, blue and green for the tests performed at 3, 7 and 28 days, shows the values obtained for 3 distinct samples denoted as S1, S2 and S3.

Table 6 presents the average variation of values for the compressive strength and density obtained from the measurements made on the samples after the 28-day drying period.

To determine the heat transfer coefficient, measurements were made on a set of three cubic samples after 28 days of drying. The measurements were carried out using ISOMET 2114 – a portable system for measurement of the heat transfer properties of materials, as shown in Figure 5.

The results obtained after measurement are presented in Table 7.

Table 7 shows the relationship between density and the heat transfer coefficient. The lower the density, the lower the heat transfer coefficient. This is characteristic of insulating materials (Constantine et al., 2018; Faiz Ahmed et al., 2022).

Table 6

Variation of density and mechanical strength with drying time

|

Sample |

Average values for |

Drying time (days) |

|

|

Compressive strength (MPa) |

Density (kg/m3) |

||

|

S 1, 2, 3 after 3 days |

0.071 |

468 |

3 |

|

S 1, 2, 3 after 7 days |

0.121 |

445 |

7 |

|

S 1, 2, 3 after 28 days |

0.238 |

302 |

28 |

Table 7

Values for heat transfer coefficient after 28 days of drying time

|

Probe |

Heat transfer coefficient λ[W/m*K] |

λ med |

Dry mass [kg] |

Density [kg/m3] |

|

Sample 1 at 28 days |

0.0728 0.0733 0.0739 |

0.0733 |

1.053 |

312 |

|

Sample 2 at 28 days |

0.0690 0.0696 0.0697 |

0.0694 |

1.009 |

299 |

|

Sample 3 at 28 days |

0.0647 0.0654 0.0655 |

0.0652 |

1.000 |

296 |

DISCUSSION

The size of the hemp particles, both length and diameter, influences the size of the air voids contained in the volume of the molded parts. This influences the variation of the heat transfer coefficient depending on the density of the obtained composite material. At the same time, the ratio between the mass of hemp and the mass of binder used determines the values of mechanical resistance and specific weight. The amount of water used in the mixture must take into account the highly hygroscopic behavior of the base material used, as well as the amount of binder that it must hydrate. The mixture must be made in a sequence that limits the absorption of water by the woody part and at the same time allows the total hydration of the binder mass. Too much water causes a slow, heavy drying, with negative influences on the hardening process, preventing lime carbonation. The tests were carried out using industrial hemp of the Zenit variety, grown in Carei, Satu Mare County from certified seed obtained at the Agricultural Development Research Station in Secuieni, Neamt County. Subsequent tests will aim to improve the thermo-mechanical performance of hemp-concrete, starting from this basic recipe. The laboratory measurements will have the objective of identifying the influence of the materials in the recipe on the properties of the composite material obtained, so that the modification of the recipe allows a mechanical resistance greater than 0.3 MPa to be obtained, the target being to maintain the coefficient of heat transfer as close as possible to the value of 0.06 W/m x K°.

The limitations of hempcrete as a construction material arise from its mechanical resistance, the value of which does not recommend its use in structural elements. At the same time, the fact that it is strongly hygroscopic, having absorption up to 5 times higher than the initial dry weight of the hemp powder used in the mixture, means that the construction elements for which it is used must be protected against moisture. However, the wet environment does not produce mold on the surface or inside the material, due to the use of lime, which is a natural disinfectant and antifungal. Comparing the values obtained for the heat transfer coefficient of hempcrete, 0.0652, with those of polyurethane foam, 0.036, with polystyrene, 0.04, with autoclaved cellular concrete, 0.12 or with ceramic blocks with vertical voids, 0.4, we observe the thermal performance of this construction material, while at the same time, being obtained from vegetable waste and mineral binders, it can be taken into account for building envelopes and partition walls because it is eco-sustainable.

CONCLUSION

The values obtained for mechanical strength, being lower than 1 MPa, impose the restriction that hempcrete cannot be used for load-bearing elements in building construction. During the study, the highest value obtained for the compressive strength was 0.249 MPa. In future studies, possible options for improving the mechanical performance must be analyzed in order to obtain values higher than 0.3 MPa if masonry blocks are to be used. The value obtained for the heat transfer coefficient 0.0652 W/m*K and the specific low weight 296 kg/m3 offer premises for future research to analyze and understand the influence of different varieties of industrial hemp on the physical‒mechanical properties of ecological construction materials. The heat transfer coefficient values are lower than those of autoclaved cellular concrete, which is widely used in construction today because it is a material with a low specific weight, cheaper than ceramic blocks with vertical voids and is also efficient in terms of time to put into operation. As an advantage, hempcrete is an ecological material and has a heat transfer coefficient that is almost 45% lower.

Author Contributions: L.A.; writing – original draft preparation; supervision, D.N.I. All authors declare that they have read and approved the publication of the manuscript in this present form.

Funding: There was no external funding for this study.

Conflicts of Interest: The author confirms that there is no conflict of interest regarding the work presented in this article.

REFERENCES

Arrigoni, A.; Pelosato, R.; Melia, P.; Ruggieri, G.; Sabbadinid, S.; Dotelli, G. Life cycle assessment of natural building materials: the role of carbonation, mixture components and transport in the environmental impacts of hempcrete blocks. Journal of Cleaner Production. 2017, 149, 1051-1061.

Ahmed, A.T.M.F.; Islam, M.Z.; Mahmud, M.S.; Sarker, M.D.; Islam, M.R. Hemp as a potential raw material toward a sustainable world: A review. Helyon. 2022, 13, e08753. https://doi.org/10. 1016/j.heliyon.2022.e08753

Seng, B.; Magniont, C.; Lorente, S. Characterization of a precast hemp concrete. PartI: physical and thermal properties. Journal of Building Engineering. 2019, 24, 100540-10.1016.

Ingrao, C.; Lo Giudice, A.; Bacenetti, J.; Tricase, C.; Dotelli, G.; Fiala, M.; Siracusa, V.; Mbohwa, C. Energy and environmental assessment of industrial hemp for building applications: a review, Renewable and Sustainable Energy Reviews. 5, 2015, 29-42. https://doi. org/10.1016/j.rser.2015.06.002.

Magniont, C.; Escadeillas, G.; Coutand, M.; Oms-Multon, C. Use of plant aggregates in building ecomaterials, European Journal of Environmental and Civil Engineering. 2012, 16:sup1, s17-s33. https://doi.org/10.1080/19648189. 2012.682452.

Collet, F.; Pretot, S. Thermal conductivity of hemp concretes: variation with formulation, density and water content. Construction and Building Materials. 2014, 65, 612-619.

Delhomme, F.; Hajimohammadi, A.; Almeida, A.; Jiang, C.; Moreau, D.; Gan, Y.; Wang, X.; Castel, A. Physical properties of Australian hurd used as aggregatefor hemp concrete. Materials Today Communications. 2020, 24 100986. https://doi.org/10.1016/j.mtcom m.2020.100986.

Costantine, G.; Maalouf, C.; Moussa, T.; Polidori, G. Experimental and numerical investigations of thermal performance of a Hemp Lime external building insulation. Building and Environment. 2018, 131, 140-153. https://doi.org/10. 1016/j.buildenv.2017.12.037.

Green Home Institute. Introduction to natural hempcrete construction methods, https://greenhomeinstitute.org/ghi-courses/introduction-natural-hempcrete-construction-methods/ (accessed on 15 march 2021).

Arehart, J.H.; Nelson, W.S.; Srubar, W.V. On the theoretical carbon storage and carbon sequestration potential of hempcrete. Journal of Cleaner Production. 2022, 266 121846. https:// doi.org/10.1016/j.jclepro.2020.121846.

Page, J.; Sonebi, M.; Amziane, S. Design and multi-physicalproperties of a newhybrid hemp-flax composite material, Construction and Building Materials. 2017, 139, 502–512. https://doi.org/10.1016/j.conbuildmat.2016.12.037.

Sivasubramanian, J.; Gino, Y. Effect of sodium silicate on hardening property of concrete, MEPCO Schlenk Engineering College, Sivakasi, India. International Journal of Civil Engineering and Technology. 2019, 10(05), 642-650.

de Bruijn, P.B. Hemp Concretes. Mechanical properties using both shives and fibers, Licentiate Thesis, Swedish University of

Agricultural Sciences Faculty, 2003.

Perletti, M.A. Sustainable building with hemp. Guide to the use in construction of a natural and innovative material, Rimini: Maggioli Editor, 2020.

Tronet, P.; Lecompte, T.; Picandet, V.; et al. Study of lime hemp concrete (LHC) -mix design, casting process and mechanical behavior. Cement and Concrete Composites. 2016, 67, 60-72.

Fernea, R.; Manea, D.L.; Plesa, L.; Iernuțan, R.; Dumitran, M. Acoustic and thermal properties of hemp-cement building materials, Procedia Manufacturing, 2019, 32, 208-215.

Dartois, S.; Mom, S.; Dumontet, H.; Hamida, A.D. An iterative micromechanical modeling to estimate the thermal and mechanical properties of polydisperse composites with platy particles: application to anisotropic hemp and lime concretes. Construction and Building Materials. 2017, 152, 661-671.

Pochwała, S. The Heat Conductivity Properties of Hemp–Lime Composite Material Used in Single-Family Buildings, Materials, building materials. Energy Procedia. 2020, 132, 189-194.

Colinart, T.; Glouannec, P.; Chauvelon, P. Influence of the setting process and the formulation on the drying of hemp concrete. Construction and Building Materials. 2012, 30, 372-380. https://doi. org/10.1016/j.conbuildmat.2011.12.030.

Abdellatef, Y.; Kavgic, M. Thermal, microstructural and numerical analysis of hempcrete microencapsulated phase change material composites, Applied Thermal Engineering. 2020, 178, 11552. http://dx.doi.org/10.1016/j.applth ermaleng.2020.115520.

Antonov, Y.I.; Jensen, R.L.; Møldrup, P.; Pomianowski, M.Z. Comparison of salt solution and air drying methods for moisture fixation in highly porous building materials. Energy Procedia. 2017, 132, 189-194. https://doi.org/ 10.1016/j.egypro.2017.09.753.

Academic Editor: Dr. Isabela Simion

Publisher Note: Regarding jurisdictional assertions in published maps and institutional affiliations ALSE maintain neutrality.