Minza I. Selele, Shaaban M. Mgana

ABSTRACT. The study investigates the potential of coconut husks in purifying biogas, a common issue in the use of biogas due to the high costs and environmental impact of expensive purification technologies. The study used an experimental setup generating biogas from kitchen waste and analysed its composition using an industry-standard biogas analyser. Coconut husks could remove hydrogen sulphide (H2S), with a high percentage removal efficiency of 54% at a column length of 0.5 m from the inlet. Based on the results, 2 kg of coconut husk could purify 837 L of biogas, with a removal efficiency of approximately 62%, before exhaustion. This suggests that coconut husks can be used in biogas purification to remove H2S, which is the most challenging component as it can corrode metal parts when used at high concentrations above 750 ppm. Further research is needed on large-scale purification using coconut husks at high pressure to allow more gas adsorption by the purification media.

Keywords: adsorption capacity; biogas composition; biogas purification; coir pith; coir fibre.

Cite

ALSE and ACS Style

Selele, M.I.; Mgana, S.M. Use of coconut husks to facilitate the removal of H2S from biogas. Journal of Applied Life Sciences and Environment 2023, 56 (3), 375-386.

https://doi.org/10.46909/alse-563106

AMA Style

Selele MI, Mgana SM. Use of coconut husks to facilitate the removal of H2S from biogas. Journal of Applied Life Sciences and Environment. 2023; 56 (3): 375-386.

https://doi.org/10.46909/alse-563106

Chicago/Turabian Style

Selele, Minza I. and Shaaban M. Mgana. 2023. “Use of coconut husks to facilitate the removal of H2S from biogas” Journal of Applied Life Sciences and Environment 56, no. 3: 375-386.

https://doi.org/10.46909/alse-563106

View full article (HTML)

Use of Coconut Husks to Facilitate the Removal of H2S From Biogas

Minza I. SELELE* and Shaaban M. MGANA

Department of Environmental Science and Management, School of Engineering and Environmental Studies (SEES), Ardhi University, Dar es Salaam, Tanzania; e-mail: smmgana@gmail.com

*Correspondence: minza.selele@gmail.com

Received: Oct. 04, 2023. Revised: Nov. 04, 2023. Accepted: Nov. 07, 2023. Published online: Nov. 28, 2023

ABSTRACT. The study investigates the potential of coconut husks in purifying biogas, a common issue in the use of biogas due to the high costs and environmental impact of expensive purification technologies. The study used an experimental setup generating biogas from kitchen waste and analysed its composition using an industry-standard biogas analyser. Coconut husks could remove hydrogen sulphide (H2S), with a high percentage removal efficiency of 54% at a column length of 0.5 m from the inlet. Based on the results, 2 kg of coconut husk could purify 837 L of biogas, with a removal efficiency of approximately 62%, before exhaustion. This suggests that coconut husks can be used in biogas purification to remove H2S, which is the most challenging component as it can corrode metal parts when used at high concentrations above 750 ppm. Further research is needed on large-scale purification using coconut husks at high pressure to allow more gas adsorption by the purification media.

Keywords: adsorption capacity; biogas composition; biogas purification; coir pith; coir fibre.

INTRODUCTION

It is estimated that each year, 61.7 million tonnes of coconut are produced in 92 countries on approximately 1.8 million hectares of land (Swarnam, 2016). Tanzania is the largest producer of coconut in Africa, whereas globally, the two largest producers are Indonesia and the Philippines (Punchihewa, 1999).

In Tanzania, approximately 95% of the coconuts are produced on a small scale, and only 5% are produced on medium- and large-scale farms (Pushpakumara et al., 2013). The coconut husk waste generated in Tanzania amounts to 145,124.7 tonnes per year (Aslam et al., 2021).

The main components of coconut husk are fibre (30%) and pith (70%), with a high lignin and phenolic compound content (Panyakaew and Fotios, 2011). The useful products from coconut husk are coir fibre and coir pith (coir dust) (Prabhu and Thomas, 2002). During the extraction of coir fibres from coconut husk, coir pith is generated as a biomass residue (Radhakrishnan, 2012). Lignin, cellulose and hemicellulose are the main biochemical components of husk (Pandiselvam et al., 2021). Coir dust is rich in lignins and tannins (Etim, 2016; Israel et al., 2011), highly hydrophilic and chemically reactive in such a way that its internal structure is a thin hollow that allows for the pith to absorb 10 times its weight in water (Greer, 2008). The organic and mineral elements in the coir include pectin and hemicellulose, lignin and cellulose, potassium, calcium, magnesium, nitrogen and protein (Tooy et al., 2022). As reported by James and Yadav (2021), structural stability, high absorptivity and porous structure (bio-adsorbents) are the properties that make coconut husks (coir) beneficial for the treatment of wastewater.

Dried coconut husks applied as a source of fuel (Pushpakumara et al., 2013), to remove odour from septic tank chambers and manholes and for gardening to prevent soil moisture loss (Greer, 2008; Pandiselvam et al., 2021). They are also used in the production of floor mats, mattresses, door mats, ropes, brushes, fishing nets and as fuel in different forms (Pandiselvam et al., 2021). The fibres are made into a variety of products, including geotechnical netting for erosion prevention (Greer, 2009). In Thailand, coconut husks are used to cultivate seedlings and plants as fertiliser or coir fibre, leaving a large amount of coconut coir (0.41 million tonnes/year) that is not adequately used (Rawangkul et al., 2010).

Although it has many advantages and is available in large quantities, coir cannot be fully used for production and storage due to the release of phenolic compounds, causing serious waste problems, wildfires and groundwater contamination (Obeng, 2020; Prabhu and Thomas, 2002). Coconut husks are often thrown into embankments and left out in the open as waste, where they take 8 to 10 years to decompose (Corradini et al., 2009). Using coir pith as fuel results in the release of large amounts of carbon dioxide and smoke (Ravindranath and Radhakrishnan, 2016), and coir pith is slowly decomposed because the ratio of pentosan to lignin is less than 0.5 (Thamban, 2000). It is recalcitrant and accumulates in the surroundings, causing environmental pollution and becoming a breeding ground for mosquitoes and other insects (Corradini et al., 2009). Since coconut husk is light, it is easily blown away by wind, causing air pollution (Reghuvaran, 2013). The leaching of coir pith is harmful to aquatic and soil microorganisms (Paramanandham and Ross, 2015).

In this context, it is crucial to develop a method to adequately dispose of this material and simultaneously increase its value, promote the use of natural products and ensure good environmental management. Isa et al. (2015) stated that considering the use of agricultural waste (such as coconut fibre or pith) as carbon sequestration agents can open up new avenues to use large amounts of carbon in different industries as they are generally rich in cellulose and lignin, making them good adsorbents. According to Dan (1993), in some parts of India, coir pith is used to produce bricks and particle boards. Mixing cow dung and coir pith at a 4:1 ratio increases biogas production (Pillai et al., 1981).

The reuse of coir is important to control pollution caused by the accumulation of coconut husks (Namasivayam and Sangeetha, 2008). According to previous studies, carbonised coconut husk extract can purify dyeing wastewater and remove arsenic, copper, chromium, mercury, nickel, organic substances and pesticides from aqueous solutions (Namasivayam and Kadirvelu, 1994). According to Santawee et al. (2019), lignin and holocellulose extracted from coir pith play an important role in trimethylamine adsorption.

Biogas is an important renewable energy source that can play a major role in meeting the world’s energy needs (Ahmad et al., 2021). It is a mixed fuel that contains energy-useless, environmentally harmful and property-damaging acids (e.g., H2S and CO2) and uses electricity instead (Peluso et al., 2019). However, due to the presence of impurities (CO2, H2S), biogas needs to be modified to increase its economic viability and sustainability (Ahmad et al., 2021). The removal of H2S can be achieved using various technological methods (biotechnology, vacuum, adsorption technology and membrane technology) (Zulkefli et al., 2017). According to Sivapragasam (2008), although several studies have been conducted on the use of agricultural products, coconut seems to be the most popular one, including coconut husks, because cellulose and lignin, which contain hydroxyl groups, constitute 60% of the husks (Neto et al., 2013; Wang et al., 2013). According to Hasfalina et al. (2015), untreated coconut husk is an excellent adsorbent for methylene blue (MB), providing an efficient method to adsorb dyes in wastewater instead of using expensive adsorbents such as activated carbon. Chowdhury and Fatema (2016) confirmed the adsorption capacity of coconut husk extract-based biosorbents for dyes and heavy metals.

This study investigated the feasibility of using virgin coconut husk (fibres and pith) as adsorbent material to remove H2S from biogas. Since most of the studies conducted on the adoption of gaseous pollutants used activated materials such as activated carbon, there is a need to use unprocessed coconut husk (coir) for purifying biogas by removing H2S through an adsorption mechanism since it is rich in cellulose and lignin (potential pollutant adsorbents). This material is the least expensive and most environmentally friendly medium that can upgrade biogas quality.

MATERIALS AND METHODS

Preparation of the purification medium

Coconut husks were collected from Mlalakuwa Street, a neighbourhood of Ardhi University in Dar es Salaam, and sun-dried for 4 days. Subsequently, the hard outer layer (exocarp) of the coconut was removed. The remaining coir fibres and pith were shredded into smaller pieces to increase their surface area (Figure 1, C), sieved (12.50-mm mesh; Figure 1, C and D) and packed into the column (Figure 1, E).

Experimental setup

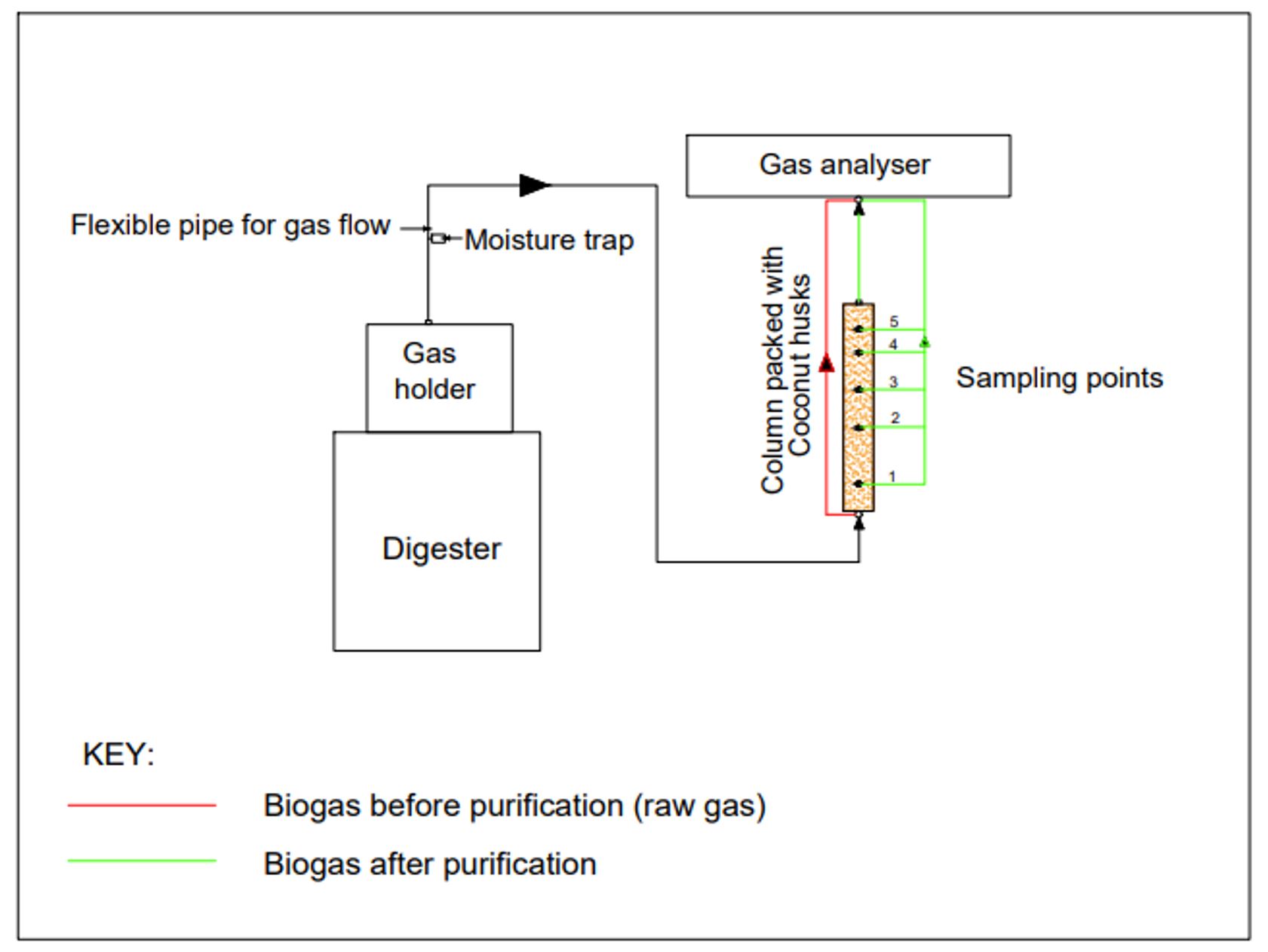

The biogas to be purified was generated from kitchen waste in a 1-m3 floating drum biogas reactor. A biogas purification column with a length of 3 m and a diameter of 90 mm was used. Briefly, 2 kg of sieved coconut husks were packed into the purification column and compacted to increase the surface area in the purification system. Prior to purification, raw biogas was allowed to pass from the gas holder through a 6.35-mm hose pipe directly to the biogas analyser (GR 5500) to check its composition in terms of CH4, CO2 and H2S. During purification, raw biogas from the gas holder, with an average composition of 61.2% CH4, 38.5% CO2 and 1,359.3 ppm H2S, was allowed to pass through the purification column (a column packed with 2 kg of shredded coconut husks) at a flow rate of 12 L/min. The purification column had six sampling points; each point was connected to the gas analyser to record the biogas composition (CH4, CO2 and H2S) after purification (Figure 2). During purification in the column, the sampling points were monitored by opening and closing using taps (see Figure 2).

Determination of adsorption capacity, exhaustion rate and removal efficiency

Adsorption capacity (mg/gm)

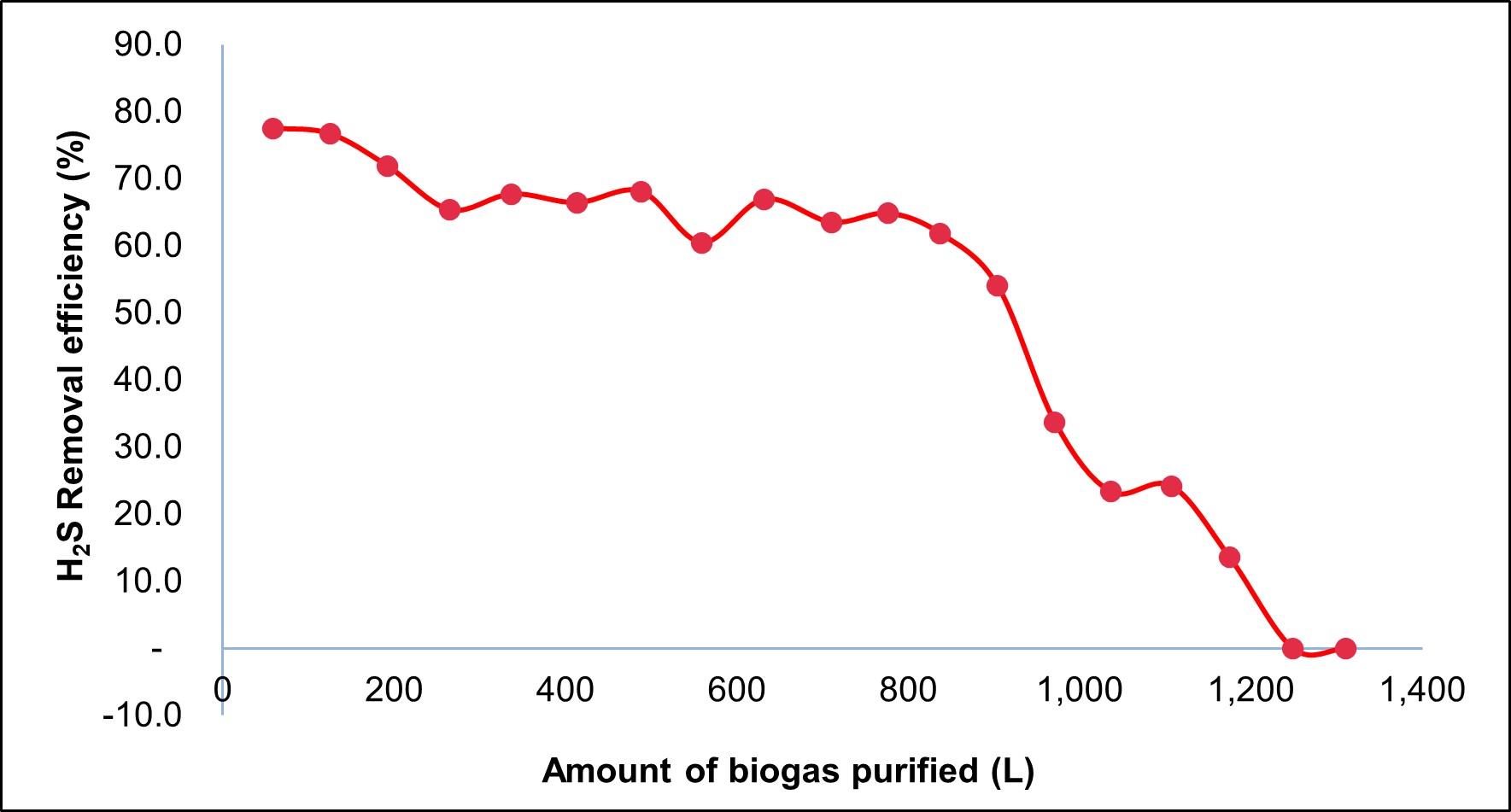

The adsorption capacity of coconut husks was calculated using Equation 1:

where: C0 = initial concentration in ppm; Ct = concentration at equilibrium; m = mass of the adsorbent; V = volume of gas containing H2S.

A = Dried coconut husks; B = shredder; C = sieve; D = sieved coconut husks; E = purification column Figure 1 – Preparation of the coconut material used for biogas purification

The weight of H2S was deducted by using the concentration of H2S in ppm and the volume of H2S during purification, applying the following equation: Weight of H2S = Concentration of H2S × Volume of biogas passed during purification.

Exhaustion rate

The exhaustion rate of coconut husks was calculated as a function of the volume of the biogas passed through the purification column and the H2S concentration in the raw biogas, considering the mass of coconut husks packed in the column, as shown in Equation 2. The exhaustion rate could also be calculated based on the mass (amount of H2S) adsorbed over the 2 kg of coconut husks and the time it takes to pass through the adsorption column (Equation 3). Equation 2 and Equation 3 were used to determine the exhaustion rate (ppm L/kg.min) or (g/kg.min):

![]()

where: Ct = concentration of H2S at time t (ppm); C0 = initial H2S concentration in raw biogas (ppm); g = cumulative volume of the purified biogas (L); W = mass of dry adsorbent (coconut husks) (kg); t = time needed for the gas to be adsorbed (min).

where: Q0 = initial weight of H2S before adsorption (g); Qt = final weight of H2S after adsorption at time t (g); W = weight of adsorbed coconut husks (kg); t = time needed for the biogas to pass through the column (min).

Removal efficiency

The hydrogen sulphide (H2S) removal efficiency using coconut husks was calculated using Equation 4:

![]()

where C0 and Ct (ppm) = initial and equilibrium concentrations at any time.

Statistical analysis

Statistical analyses were performed to compare column performance for H2S removal at the six sampling points. Analysis of variance (ANOVA) was applied to determine the differences in percentage removal of H2S from each sampling point in the column, using Microsoft Excel and Instant.

RESULTS AND DISCUSSION

Hydrogen sulphide removal from biogas

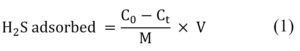

The average initial H2S concentration of raw biogas was higher, 1,359 ppm, than that of the biogas that had passed though the column (452 ppm). The concentration of H2S tended to decrease along the column, with a higher H2S removal efficiency at the first sampling point of the column 0.5 m from the inlet, most likely because of the high compaction of the coconut husks at this sampling point. Along the column, H2S removal varied, which can be explained by the short circuit of the biogas because there was no uniform compaction in the biogas purification units. Hydrogen sulphide was effectively removed from days 1 to 15, and on day 16, the removal of H2S was low at all sampling points. From days 17 to 19, no H2S was removed (see Figure 3).

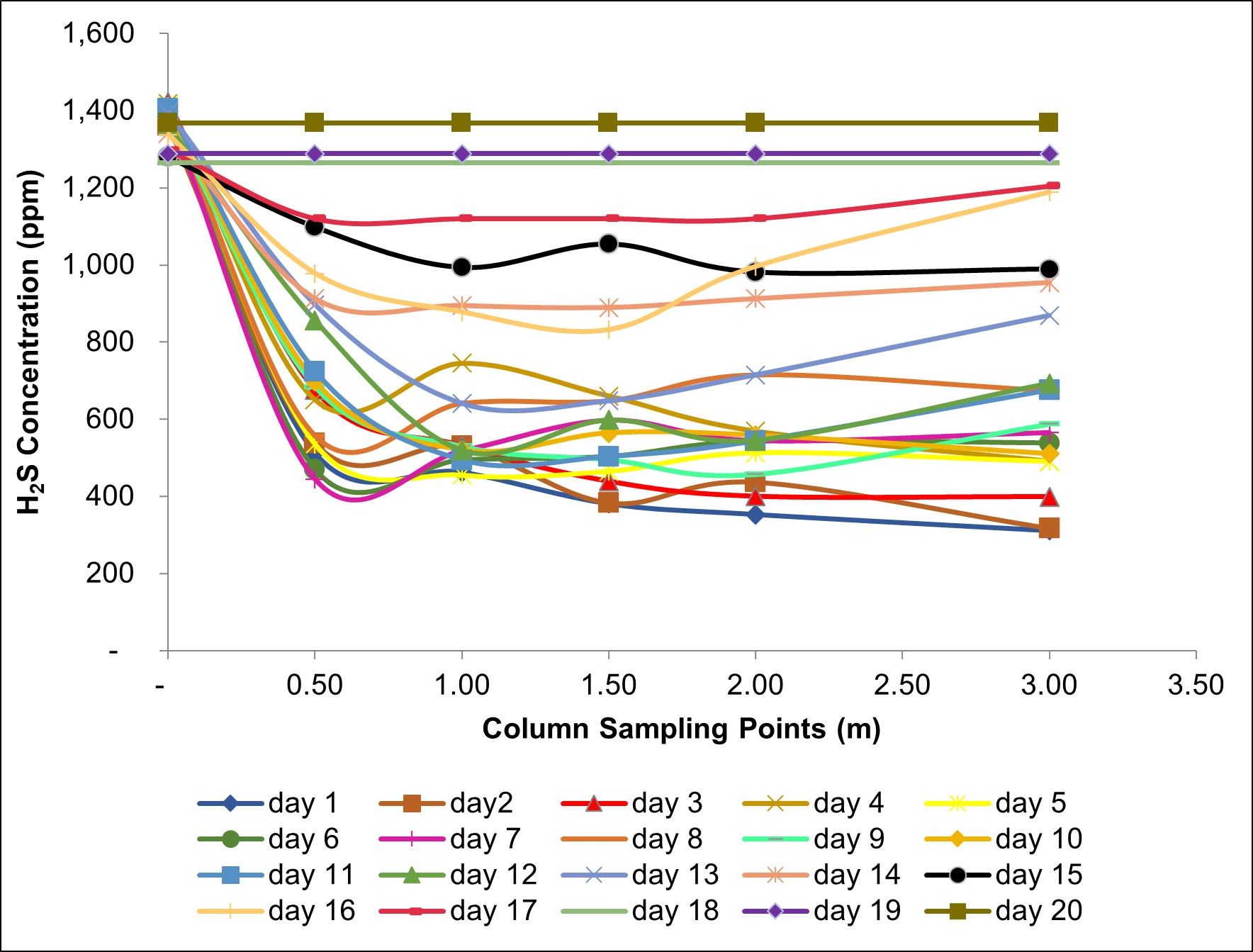

Removal efficiency at the different purification units

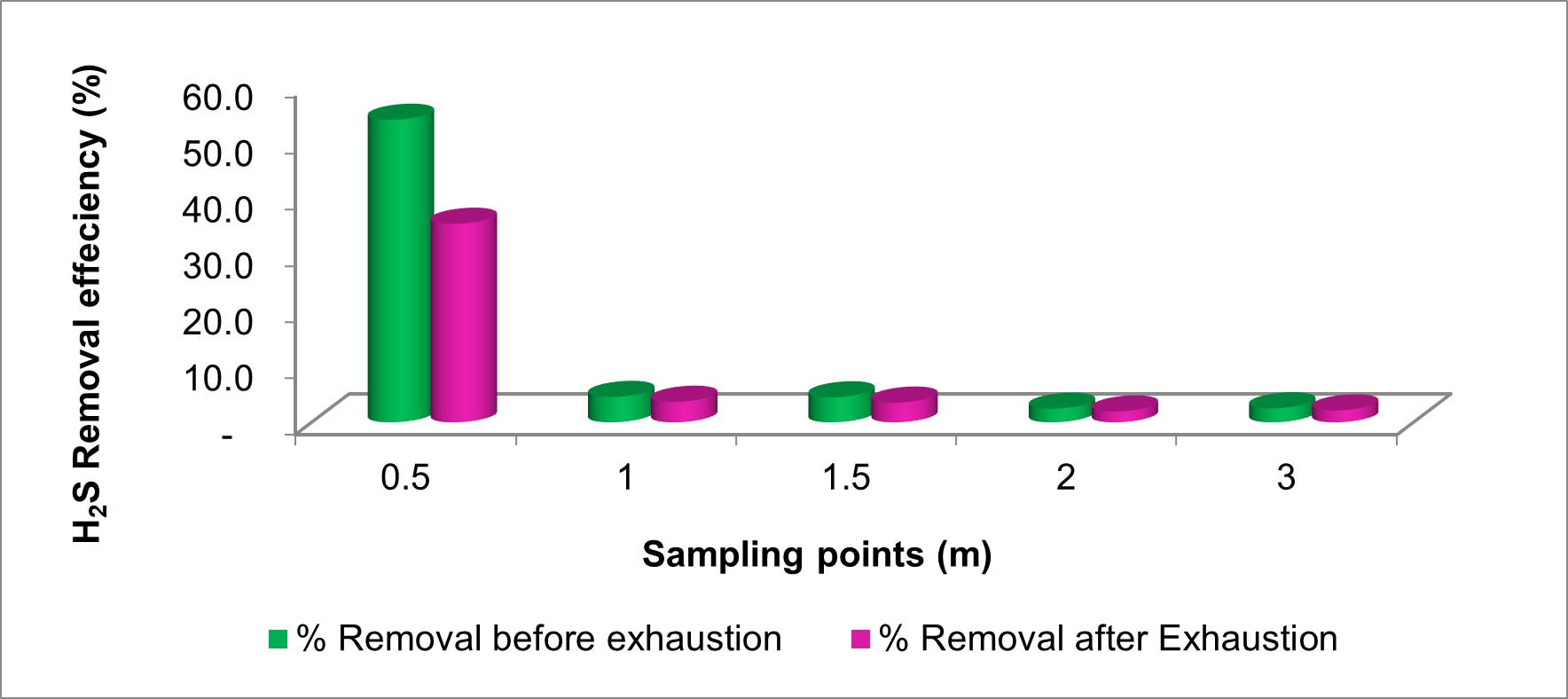

The H2S removal efficiency differed among the different sampling points. At the beginning of the experiment, the coconut husks had a high ability to purify the biogas, and this ability tended to decrease as the volume of biogas passed through the column increased. Figure 4 shows the removal efficiency at different experimental runs corresponding to the cumulative volume of the biogas that passed through the purification column. Based on the results, 2 kg of coconut husk could purify approximately 837 L of biogas with an average H2S concentration of 452 ppm at a removal efficiency of about 62% (Figure 4). This indicates that the more biogas passed through the purification system, the lower the purification efficiency. Most likely, with a higher biogas volume, the adsorption surface area was reduced, which decreased the H2S removal efficiency. In our study, the H2S removal efficiency was lower than that reported by Zhao et al. (2010) when H2S was removed from biogas by adsorption using impregnated activated carbon. The lower performance in this study was due to the low pressure applied during the experiment as more gas is adsorbed at higher pressure; with decreasing pressure, the gas is released or desorbed (Zhao et al., 2010). By comparing the amount of biogas purified at each sampling point, at 0.5 m from the inlet, more than 54% of the H2S was removed compared to other sampling points, before exhaustion and 34% after exhaustion (see Figure 5).

Figure 3 – Hydrogen sulphide removal along the purification column

Figure 4 – Hydrogen sulphide removal efficiency as a factor of biogas volume

Figure 5 – Hydrogen sulphide removal efficiency along the purification column

Removal efficiency based on the sampling point (distance from the inlet)

A high removal efficiency was achieved at 0.5 m from the inlet, with removal efficiencies of 54% and 35% before and after exhaustion, respectively, whereas at the other sampling points (1, 1.5, 2 and 3 m), the removal efficiency was less than 5%. Based on the ANOVA results, the removal efficiency at 0.5 m was highly significant (P = 0.0001), and the variation among the sampling point means was significant. Malina (1992) reported that the concentration of H2S required before the use of biogas should be less than 750 ppm. In the present study, 2 kg of coconut husks could purify 837 L of biogas with an average H2S concentration of 452 ppm. This indicates that coconut husks have a high potential for purifying biogas, meeting the requirements regarding the H2S concentration of biogas.

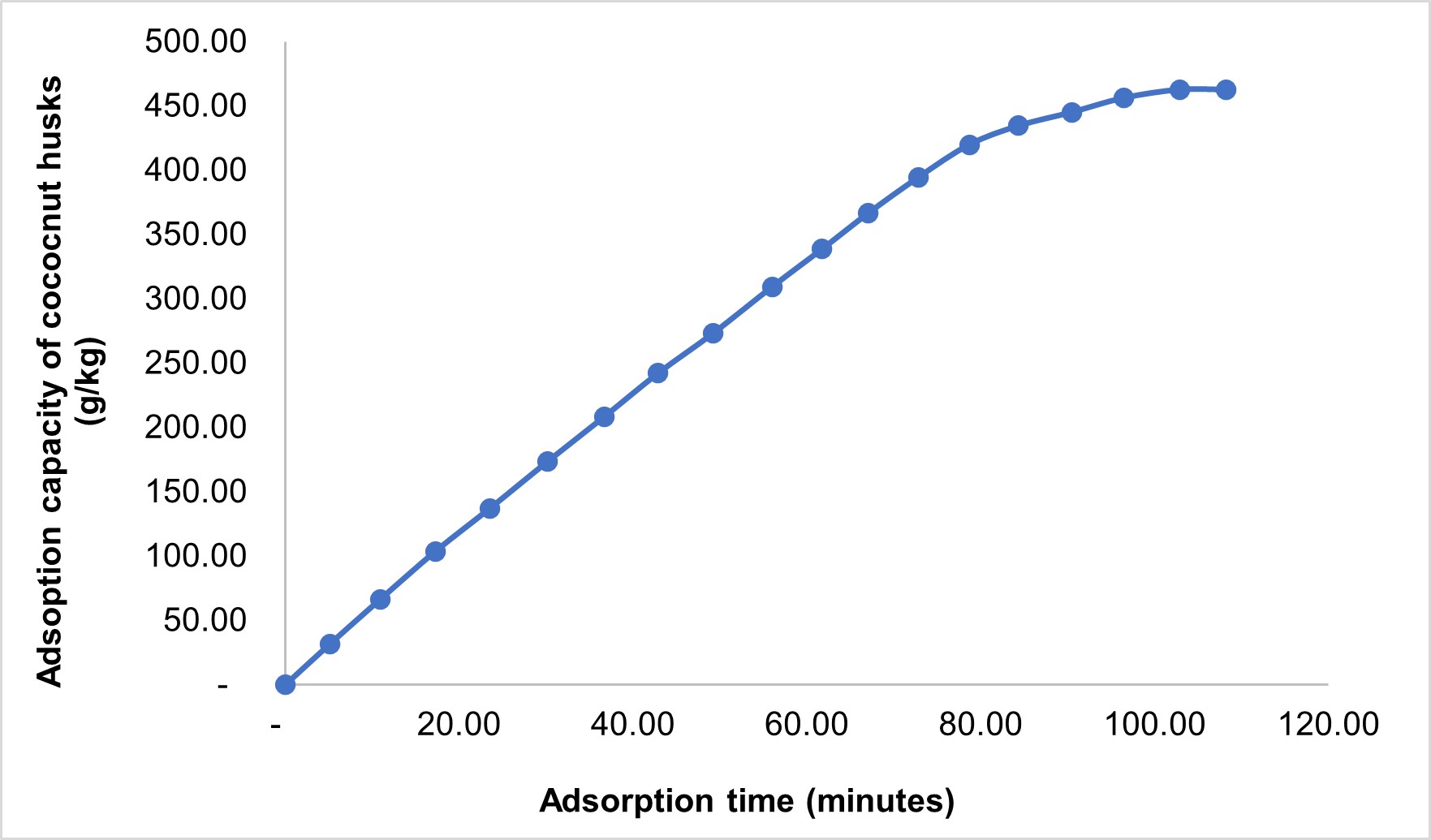

Adsorption capacity of coconut husks

Figure 6 shows the H2S adsorption profiles of coconut husks. Based on the results, 2 kg of coconut husks adsorbed a maximum of 462.89 g (H2S)/kg coconut husk. As shown in Figure 6, from 0 to 78 min, H2S adsorption increased, as indicated by a sharp and linear increase. However, between 78 and 108 min, the adsorption capacity graph tends to flatten. The rapid adsorption rate observed between 0 and 78 min may be due to the high adsorbent surface area of the coconut husks, and the gradual decrease in adsorption capacity occurred because the adsorbents approached saturation or maximum adsorption capacity. This finding is similar to the result observed by Abdulsalam (2016), who reported a sharp linear increase in the graph during the adsorption of CO2 between 0 and 10 min, followed by a flattening of the curve from 10 to 20 min.

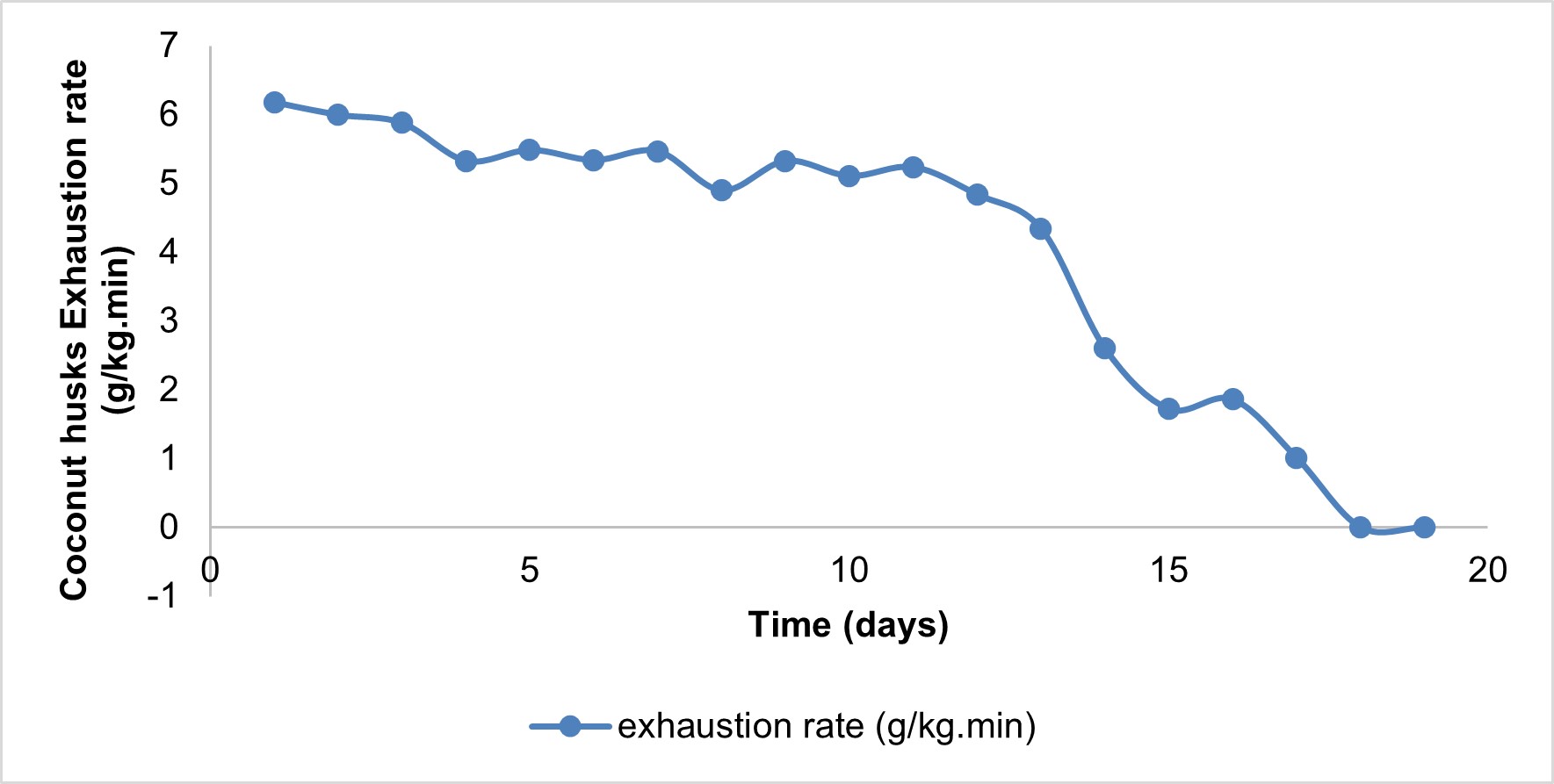

Exhaustion rate of coconut husks in the removal of hydrogen sulphide

The exhaustion rate of coconut husks depends on the volume of gas passing through the coconut husks and increases as the amount of purified gas increases. Figure 7 shows that the ability of coconut husks to adsorb H2S decreased as the amount of biogas passed through the purification column increased. At the beginning of the experiment (day 1), 6.18 g of H2S could be adsorbed per minute, and subsequently, the adsorption rate decreased until it reached 0 g/kg/min on day 18, indicating that no H2S was adsorbed anymore because the surface of the husk was saturated.

Figure 6 – Hydrogen sulphide adsorption capacity over time

Figure 7 – Exhaustion rate of coconut husks

CONCLUSIONS

Coconut husk can potentially be used in biogas purification to remove H2S, which is the most challenging component as it corrodes metal parts when used at concentrations above 750 ppm. In this study, 2 kg of coconut husk could purify approximately 800 L of biogas with an average H2S concentration of 452 ppm, with a removal efficiency of 62% before exhaustion. The highest H2S removal efficiency was achieved at 0.5 m from the inlet point. Based on our findings, coconut husks can be used in simple, cost-effective biogas purification systems, obtaining biogas with fewer or no impurities (H2S).

Author Contributions: Conceptualization MIS and SMM; Methodology MIS; Analysis MIS; Investigation MIS; Resources MIS; Data curation MIS; Writing MIS; Review SMM; Supervision SMM.

Conflicts of Interest: There are no conflicts of interest regarding this article.

REFERENCES

Ahmad, W.; Sethupathi, S.; Kanadasan, G.; Lau, L.C.; Kanthasamy, R. A review on the removal of hydrogen sulfide from biogas by adsorption using sorbents derived from waste. Reviews in Chemical Engineering. 2021, 37, 407-431. https://doi.org/10.1515/revce-2018-0048.

Aslam, Z.; Li, H.; Hammerton, J.; Andrews, G.; Ross, A.; Lovett, J.C. Increasing Access to Electricity: An Assessment of the Energy and Power Generation Potential from Biomass Waste Residues in Tanzania. Energies. 2021, 14, 1793. https://doi.org/10.3390/en14061793.

Chowdhury, M.A.; Fatema, K.J. Review of renewable biosorbent from coir pith waste for textile effluent treatment. International Journal of Textile Science. 2016, 5, 132-140. http://dx.doi.org/10.5923/j.textile.20160506.02.

Corradini, E.; Rosa, M.D.F.; Macedo, B.P.D.; Paladin, P.D.; Mattoso, L.H.C. Chemical composition, thermal and mechanical properties for cultivars of immature coconut fibres. Revista Brasileira de Fruticultura. 2009, 31, 837-846.

Dan, T.K. Development of lightweight building bricks using coconut pith, Indian Coconut Journal. 1993, 23, 12-19.

Etim, U.J.; Umoren, S.A.; Eduok, U.M. Coconut coir dust low-cost adsorbent for the removal of cationic dye from an aqueous solution. Journal of Saudi Chemical Society. 2016, 20, S67-S76. https://doi.org/10.1016/j.jscs.2012.09.014.

Greer, S. Converting coconut husks into binderless particle board. MSc Thesis, Baylor University, Waco, Texas, 2009.

Isa, N.; Chin, I.I.; Hamzah, A.A.; Roslan, S.N.; Azman, I.N.; Ahmad, A.A. Performance of Green Coconut Coir as the Potential Adsorbent for Sequestration of Carbon Dioxide in Natural Gas, Proceedings of 2015 International Conference on Biological and Environmental Science 09-13 September 2015, Sarajevo, Bosnia and Herzegovina, https://www.icoest.eu/sites/default/files/icoest-2015-final-book_of_proceedings_0_edited.pdf.

Israel, A.U.; Ogali, R.E.; Akaranta, O.; Obot, I.B. Extraction and characterization of coconut (Cocos nucifera L.) coir dust. Songklanakarin Journal of Science & Technology. 2011, 33, 717-724.

Hasfalina, C.B.M.; Akinbile, C.O.; Jun, C.X. Coconut husk adsorbent for the removal of methylene blue dye from wastewater. BioResources. 2015, 10, 2859-2872. https://doi.org/10.15376/biores.10.2.2859-2872.

James, A.; Yadav, D. Valorization of coconut waste for facile treatment of contaminated water: a comprehensive review (2010–2021). Environmental Technology & Innovation. 2021, 24, 102075. https://doi.org/10.1016/j.eti.2021.102075.

Namasivayam, C.; Kadirvelu, K. Coirpith, an agricultural waste by-product, for the treatment of dyeing wastewater. Bioresource Technology. 1994, 48, 79-81. https://doi.org/10.1016/0960-8524(94)90141-4.

Namasivayam, C.; Sangeetha, D. Application of coconut coir pith for the removal of sulfate and other anions from water. Desalination. 2008, 219, 1-13. https://doi.org/10.1016/j.desal.2007.03.008.

Neto, V.O.S.; Oliveira, A.G.; Teixeira, R.N.P.; Silva, M.A.A.; Freire, P.T.C.; Keukeleire, D.D.; Nascimento, R.F. Use of coconut bagasse as an alternative adsorbent for separation of copper (II) ions from aqueous solutions. Isotherms, kinetics and thermodynamic studies. BioResources. 2011, 6, 3376-3395. http://dx.doi.org/10.15376/biores.6.3.3376-3395.

Obeng, G.Y.; Amoah, D.Y.; Opoku, R.; Sekyere, C.K.K.; Adjei, E.A.; Mensah, E. Coconut Wastes as Bioresource for Sustainable Energy: Quantifying Wastes, Calorific Values and Emissions in Ghana. Energies. 2020, 13, 2178. https://doi.org/10.3390/en13092178.

Pandiselvam, R.; Manikantan, M.R.; Ramesh, S.V.; Rintu, V.F.; Athira, S.; Beegum, S.; Mathew, A.C. Tender Coconut Husk. Indian Coconut Journal. 2021, 9.

Panyakaew, S.; Fotios, S. New thermal insulation boards made from coconut husk and bagasse. Energy and buildings. 2011, 43, 1732-1739.

Paramanandham, J.; Ross, R.P. Lignin and cellulose content in coir waste on subject to sequential washing. Journal of Chemistry and Chemical Research (India). 2015, 1, 10-13.

Peluso, A.; Gargiulo, N.; Aprea, P.; Pepe, F.; Caputo, D. Nanoporous materials as H2S adsorbents for biogas purification: a review. Separation & Purification Reviews. 2019, 48, 78-89.

Pillai, K.K. Influence of coal type on devolatilization and combustion in fluidized beds. Journal of the Energy Institute. 1981, 54, 142-150.

Prabhu, S.R.; Thomas, G.V. (). Biological conversion of coir pith into a value-added organic resource and its application in Agri-Horticulture: Current status, prospects and perspective. Journal of Plantation Crops. 2002, 30, 1-17.

Punchihewa, P.G. Current status of the coconut industry. In Current advances in coconut biotechnology. Dordrecht: Springer Netherlands,1999, pp. 3 -17.

Pushpakumara, J.; Gunasema, H.; Nayanie, S.; Nimal, P. Special Report on Development of the Coconut Industry. Dar es Salaam, Tanzania. 2013, 15pp.

Radhakrishnan, S. Quantitative Evaluation of the Production of Ligninolytic Enzymes-Lignin Peroxidase and Manganese Peroxidase by P. Sajor Caju During Coir Pith Composting. CORD. 2012, 28, 10-10. https://doi.org/10.37833/cord.v28i1.107.

Ravindranath, D.A.; Radhakrishnan, S. Coir piths wealth from waste a reference. Published on the Occasion of the India International Coir Fair. 2016. http://coirboard.gov.in/wp-content/uploads/2016/07/Coir-Pith.pdf

Rawangkul, R.; Khedari, J.; Hirunlabh, J.; Zeghmati, B. Characteristics and performance analysis of a natural desiccant prepared from coconut coir. Science Asia. 2010, 36(3), 216-222. http://dx.doi.org/10.2306/scienceasia1513-1874.2010.36.216.

Reghuvaran, A.; Ravindranath, A.D. Bioconversion of coir pith as effective soil-less media for roof gardening. Advances in Applied Research. 2013, 5, 141-146.

Santawee, N.; Treesubsuntorn, C.; Thiravetyan, P. Lignin and holocellulose from coir pith are involved in trimethylamine (fishy odour) adsorption. Journal of Environmental Sciences. 2019, 79, 43-53. https://doi.org/10.1016/j.jes.2018.10.009.

Swarnam, T.P.; Velmurugan, A.; Pandey, S.K.; Roy, S.D. Enhancing nutrient recovery and compost maturity of coconut husk by vermicomposting technology. Bioresource Technology. 2016, 207, 76-84. https://doi.org/10.1016/j.biortech.2016.01.046.

Thamban, P.K. Recycling of coconut biomass for sustainable production. Indian Coconut Journal. 2000, 31, 5-6.

Tooy, D.; Longdong, I.A.; Lolowang, T.F. Technical study of small-scale coconut husk decomposing equipment to reduce coconut husk waste in North Sulawesi. IOP Conference Series: Earth and Environmental Science. 2022, 977, 012068. https://doi.org/10.1088/1755-1315/977/1/012068.

Wang, Y.Z.; Shi, X.N.; Wang, W.B.; Wang, A.Q. Synthesis, characterization and swelling behaviours of a pH-responsive CMC-g-poly (AA-co-AMPS) superabsorbent hydroel. Turkish Journal of Chemistry. 2013, 37, 149 -159.

Zhao, Q.; Leonhardt, E.; MacConnell, C.; Frear, C.; Chen, S. Purification technologies for biogas generated by anaerobic digestion. Compressed Biomethane. 2010, CSANR, Ed, 24.

Zulkefli, N.N.; Masdar, M.S.; Isahak, W.R.W.; Jahim, J.; Majlan, E.H.; Rejab, S.A.M.; Lye, C.C. Mathematical modelling and simulation on the adsorption of Hydrogen Sulfide (H2S) gas. IOP Conference Series: Materials Science and Engineering. 2017, 2. https://doi.org/10.1088/1757-899X/206/1/012069.

Academic Editor: Dr. Isabela Maria Simion

Publisher Note: Regarding jurisdictional assertions in published maps and institutional affiliations ALSE maintain neutrality.