F. Shahbazi, R. Shahbazi

ABSTRACT. The objective of this research was to evaluate and model the mechanical damage to corn seeds under impact loading. The experiments were conducted at moisture contents of 7.60 to 25% (wet basis) and at the impact energies of 0.1, 0.2 and 0.3 J, using an impact damage assessment device.

The results showed that impact energy, moisture content, and the interaction effects of these two variables significantly influenced the percentage of physical damage in corn seeds (p<0.01). Increasing the impact of the energy from 0.1 to 0.3 J caused a significant increase in the mean values of damage from 23.73 to 83.49%. The mean values of physical damage decreased significantly by a factor of 1.92 (from 83.75 to 43.56%), with an increase in the moisture content from 7.6 to 20%.

However, by a higher increase in the moisture from 20 to 25%, the mean value of damage showed a non-significant increasing trend. There was an optimum moisture level of about 17 to 20%, at which seed damage was minimized. An empirical model composed of seed moisture content and energy impact was developed for accurately describing the percentage of physical damage to corn seeds. It was found that the model has provided satisfactory results over the whole set of values for the dependent variable.

Keywords: mechanical damage; harvesting; handling; processing; impact; corn.

View full article (HTML)

Mechanical damage to corn seeds

F. Shahbazi1, R. Shahbazi1

1Lorestan University, Faculty of Agriculture, Department of Biosystems Engineering, Khorramabad, Iran

*E-mail: shahbazi.f@lu.ac.ir

Received: Apr. 10, 2018. Revised: June 27, 2018. Accepted: July 20, 2018. Published online: July 17, 2019

ABSTRACT. The objective of this research was to evaluate and model the mechanical damage to corn seeds under impact loading. The experiments were conducted at moisture contents of 7.60 to 25% (wet basis) and at the impact energies of 0.1, 0.2 and 0.3 J, using an impact damage assessment device.

The results showed that impact energy, moisture content, and the interaction effects of these two variables significantly influenced the percentage of physical damage in corn seeds (p<0.01). Increasing the impact of the energy from 0.1 to 0.3 J caused a significant increase in the mean values of damage from 23.73 to 83.49%. The mean values of physical damage decreased significantly by a factor of 1.92 (from 83.75 to 43.56%), with an increase in the moisture content from 7.6 to 20%.

However, by a higher increase in the moisture from 20 to 25%, the mean value of damage showed a non-significant increasing trend. There was an optimum moisture level of about 17 to 20%, at which seed damage was minimized. An empirical model composed of seed moisture content and energy impact was developed for accurately describing the percentage of physical damage to corn seeds. It was found that the model has provided satisfactory results over the whole set of values for the dependent variable.

Keywords: mechanical damage; harvesting; handling; processing; impact; corn.

INTRODUCTION

Harvesting and postharvest operations on modern grain farms, such as corn, negatively influence the quality of seeds. Harvesters and other machines used during harvesting, transporting, drying and conveying operations cause significant mechanical damage to seeds, i.e. skin rupture, seed fracture, etc.

The damage is produced from the mechanical interaction between biological material (seeds) and steel, rubber etc. (working elements of machines). Most authors admit that damage to seeds occurs mainly in the course of harvest and transport when the seeds are subject to accidental impact (Baryeh, 2002).

The mechanical resistance of seeds to the impact damage plays a very important role in the design of harvesting and other processing machines (Baryeh, 2002). The value of this basic information is necessary, because during operations, in these sets of equipment, seeds are subjected to impact loads, which may cause mechanical damage. Impact damage of seeds depends on a number factors, such as the velocity of impact, seed structural features, seed variety, seed moisture content, stage of ripeness, fertilization level and incorrect settings of the particular working subassemblies of the machines (Shahbazi, 2011; Shahbazi et al., 2011a).

Among the above factors, the seed moisture content and impact energy are important factors influencing the damage. Some researchers found a significant influence of the impact velocity and moisture content upon the seed damage and found that the damage increases significantly, as the energy of the impact increases and as the moisture content decreases (Khazaei et al., 2008; Khazaei, 2009; Shahbazi et al., 2011a and b). Impact damage to seeds has been the subject of much research due to the loss in product quality incurred during harvesting, handling, and processing. Researchers have used different impact damage assessment devices to conduct impact tests on seeds and simulate the impact loads that seed would be subjected (Sosnowski, 2006; Khazaei, 2009; Shahbazi et al., 2011a and b).

Because of the complex nature of impact damage to seeds, accurate designing, controlling and adjusting of threshers, harvesters, conveyors, and other processing systems is difficult. This necessitates the accurate design and the use of the automatic system for controlling and adjusting of harvesters and other processing systems.

Automatic control needs to have practical data for those involved in equipment and methods for handling seeds and a more powerful prediction model to be able to estimate the effects of several independent variables on several dependent ones.

During the last decade, various forms of multiple linear regression models have been widely considered to estimate the mechanical damage to seeds, based on the machine and crop parameters (Sosnowski and Kuzniar, 1999; Baryeh, 2002; Szwed and Lukaszuk, 2007; Khazaei, 2009; Shahbazi et al., 2001a and b; Shahbazi, 2011).

Information relating the number of corn seeds impact damage to the energy of the impact and seed moisture content and modeling the damage to seeds is limited. In light of the above facts, the objectives of this study were to:

- Evaluate the impact damage to corn seeds and determine the effects of impact energy and seed moisture content on the percentage of physical damage to seeds;

- Develop empirical models that explain the relationship between the percentage of seed physical damage and the experimental variables for corn seeds and evaluate the predictive performance of the models.

MATERIAL AND METHODS

Samples of corn seeds at optimum maturity were harvested by hand in Lorestan province, Iran, and cleaned in an air screen cleaner. The initial moisture content was 7.60% (wet basis), determined with ASAE S352.2 for edible beans (ASAE Standards, 1988). Higher moisture content samples were prepared by adding calculated amounts of distilled water, then sealing in polyethylene bags, and storing at 5ºC for 15 days. Samples were warmed to room temperature before each test and moisture content was verified. Sample mass was recorded with a digital electronic balance having an accuracy of 0.001 g.

The laboratory apparatus used to impact seeds operated in a way similar to the impacting energy instruments used by Kim et al. (2002), Oluwole et al. (2007), Shahbazi et al. (2012) and Shahbazi (2014). An aluminum drop bar (800 mm length; 25 mm external diameter; 0.2 kg) was inserted into a steel tube (750 mm length; 27 mm internal diameter; 29 mm external diameter).

In this study, the effects of impact energy (at 0.1, 0.2 and 0.3 J) and seed moisture content (at 7.60, 12.5, 15, 17.5,

20 and 25% wet basis) were studied on the percentage of physical damage in corn seeds. The range of seeds moisture is from 7.6 to 25%, as this includes the normal range of moisture levels during harvesting and postharvest processing for seeds (Khazaei, 2009).

The energy of impact ranged from 0.1, 0.2 and 0.3 J, including those happening in harvesters, separator, conve-yors, storing system, and other processing systems (Shahbazi et al., 2014). The factorial experiment was conducted as a randomized design with three replicates.

For each impact test, 100 seeds were selected randomly from each sample and impacted by using the impact device.

After each test, visual evaluation of the microscopic structural analysis of the seed (before and after the impact) was used to analyze the character of damage to the corn seed. Damaged seeds include the broken, cracked, and bruised seeds were accurately identified and sorted by visual inspection. A handheld magnifying glass was used to augment the visual inspection. The percentage of seed damage was calculated as:

Experimental data were analyzed using analysis of variance (ANOVA) and the means were separated at the 5% significance level applying Duncan’s multiple range tests in SPSS 17 software. The nonlinear regression program of SAS (SAS, 2001), was used to find and fit the best general models to the data and develop empirical models that explain the relationship between the percentage of seed damage and the experimental variables.

RESULTS AND DISCUSSION

Analysis of variance indicated that moisture content and impact energy (independent variables) created significant effects on the physical damage of corn seeds at 1% significance level (p<0.01). Impact energy had a larger influence (F=584.255) than moisture content (F=68.628) within the range studied. In addition, the interaction effect of the moisture content × impact energy significantly influenced the physical damage of bean seeds at 1% significance level (Table 1).

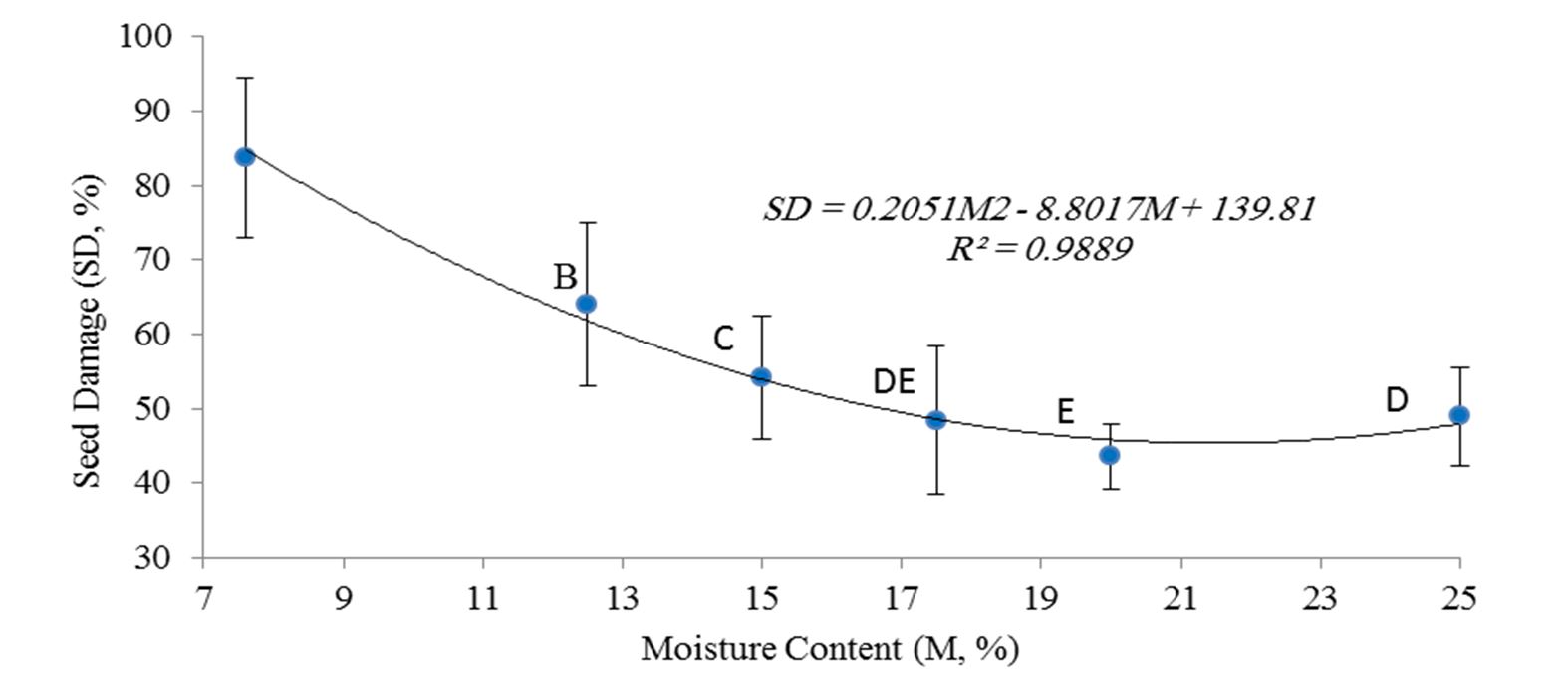

Effect of moisture content

The effect of moisture content on the level of damage to the tested seeds of corn is presented in Fig. 2. (mean values at the impact energies of 0.1, 0.2 and 0.3 J and at three replications) As follows from the relation presented in the figure, the percentage of damaged seeds decreases with increase in their moisture content. This may be related to a change in their elasticity at higher moisture level, which causes greater absorption of energy during the impact. Many researchers have also reported similar results for the other crops (Sosnowski and Kuzniar, 1999; Parde et al., 2002; Szwed and Lukaszuk, 2007; Khazaei et al., 2008; Khazaei, 2009). With increasing the moisture content from 7.6 to 20%, the mean values of the percentage damage significantly decreased from 83.75 to 43.56% (by a factor of 1.92).

Table 1

Analysis of variance (Mean square) for the percentage of mechanical damage to corn seeds as affected by moisture content and impact energy

| Source of variation | DF | Mean square | F |

| Moisture Content (MC) | 5 | 1966.637 | 68.628** |

| Impact Energy (IE) | 2 | 16742.758 | 584.255** |

| MC×IE | 10 | 216.038 | 7.539** |

| Error | 36 | 28.657 |

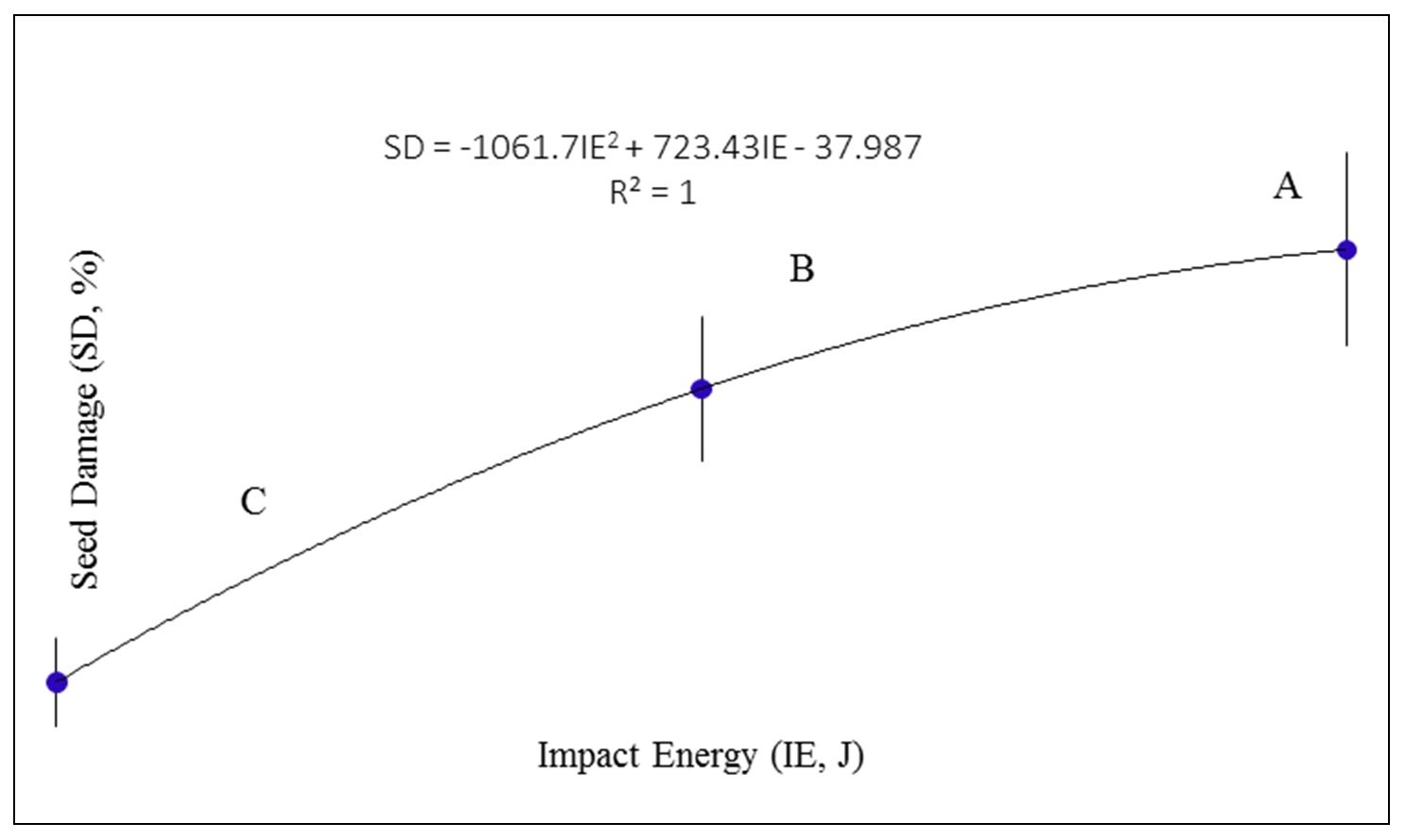

However, by a higher increase in the moisture from 20 to 25%, the mean values of damage showed a non-significant increasing trend (Fig. 1).

Figure 1 – Effects of moisture content on the percentage of damage to corn seeds. Averages with the same letter have no significant difference at the 5% significance level.

The relation of damage rate, presented in Fig. 1, is non-linear and the appearance of minimum values of damage rate at a certain moisture content range is a feature characteristic of the tested seeds. The shape of the graph in the figure show that the changes in seed damage rate plot quadratic function with fairly significantly differing coefficients at variable moisture for corn seeds. The extent of damage of impacted seeds decreased with increasing moisture and reached a minimum at a moisture level of about17.5 to 20%. Further increase in seed moisture, however, caused an increase in the number of damaged seeds. According to numerous studies, there exists a certain optimum level of moisture content for each variety at which, under the effect of impact forces, there occurs a minimum of damage to the seeds (Szwed and Lukaszuk, 2007). Therefore, In the case of corn seeds that the optimum level of moisture is about 17-20%.

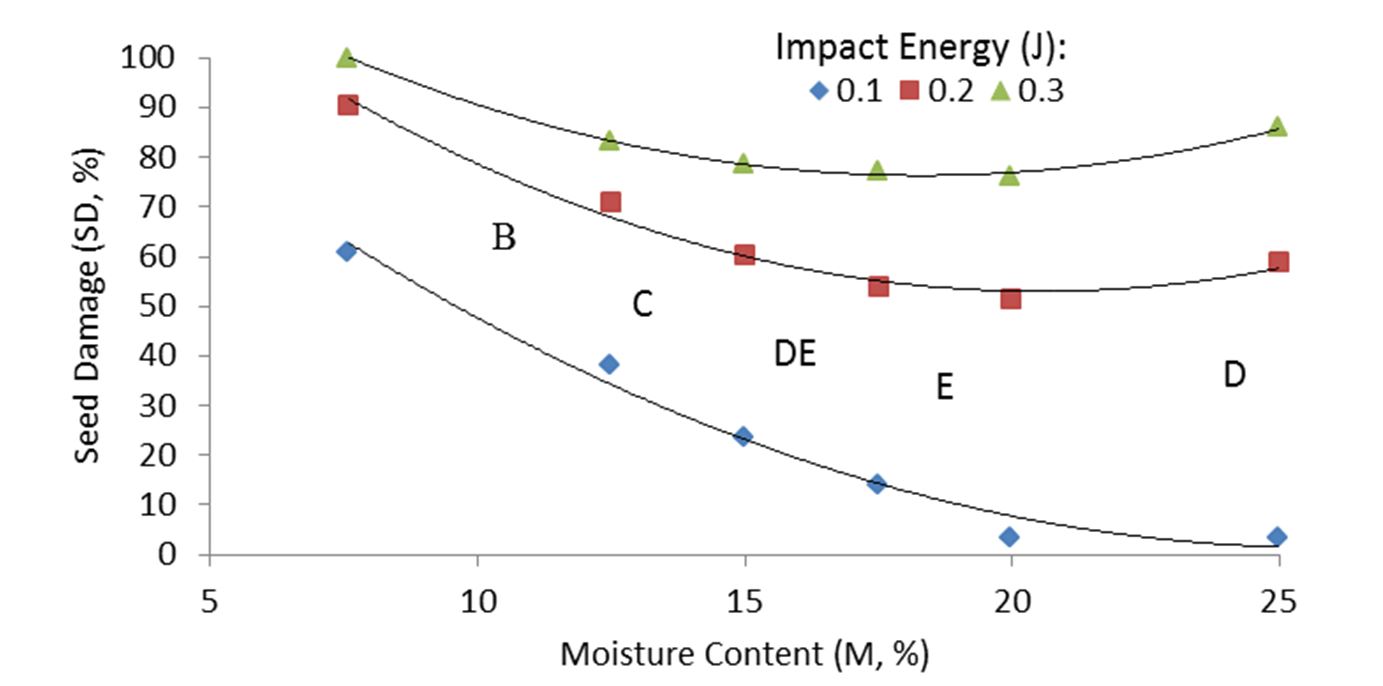

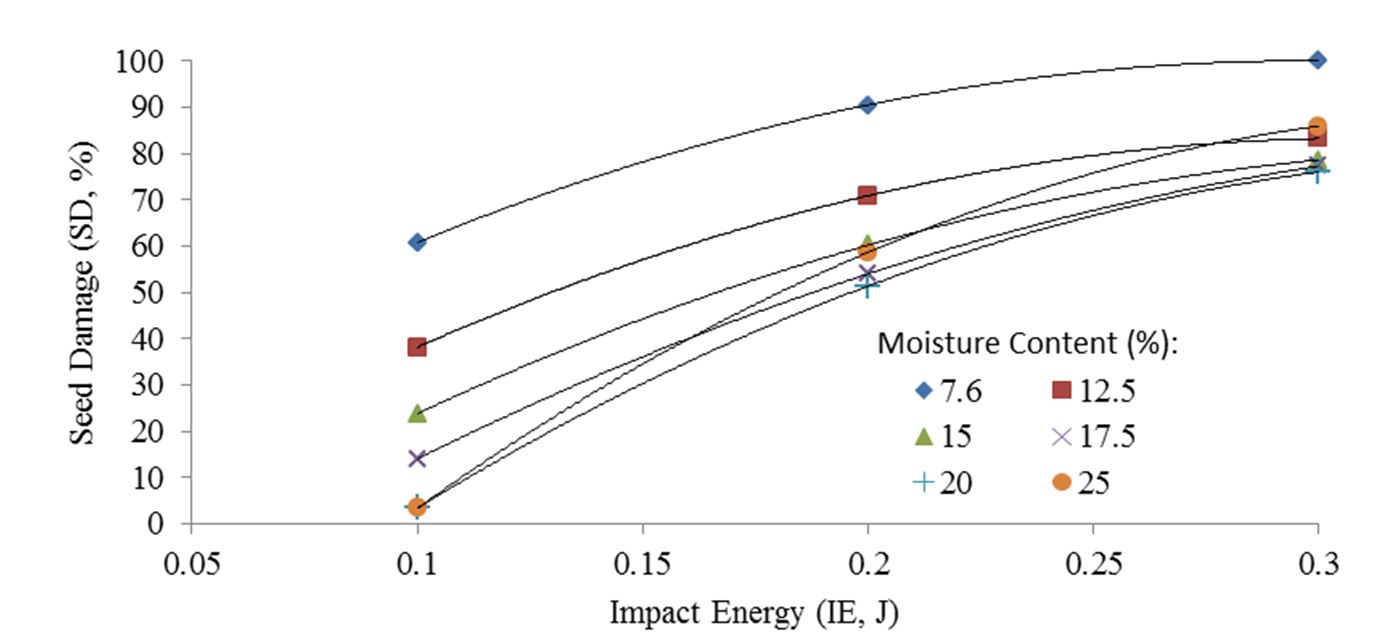

Fig. 2 shows the corn seeds physical damage variation with seed moisture content for various impact energies. As follows from the figure, for all the impact energies considered, the percentage of the seed damage decreases with an increase in their moisture content.

Figure 2 – Corn seeds impact damage variation with seed moisture content for different impact energies

These results confirm that, as the moisture content has significant effects on the elastic properties of materials of plant origin, it also has a bearing on the effects of impact damage. At higher moisture contents, the elasticity of seeds will increase, which causes that their firmness increase, thus, causes greater absorption of energy during impact and increases the resistance to damage. On the other hand, at lower moisture contents, the seeds are more brittle, thus, more prone to physical damage caused by impact (Khazaei et al., 2008; Khazaei, 2009).

As shown in Fig. 2, the rates of increase in percent damage to seeds by a decrease in their moisture content are not the same for all the levels of impact energies. The effect of moisture content on the damage is stronger at higher impact energies than at lower ones. At the critical range of the tests, when the moisture content decreased from 20 to 7.6%, the maximum rate of increase in the damage to seeds was obtained for the impact energy of 0.3 J, which was equal to 24.01% (from 100% to 75.99%). Corresponding values are equal to 57.43 and 39.13%, for the same moisture range at 0.1 and 0.2 J impact energies, respectively. Fig. 2 indicates that for all the impact energies, relations of damage rate are non-linear with seed moisture content. Regression analysis was used to find and fit the best general models for the data. Results showed that the percentage of damage to seeds was a quadratic function of their moisture content, at all the impact energies considered. Szwed and Lukaszuk (2007) observed similar behavior for other crops. The equations representing the relationship between the percentage of damage to seeds and moisture content for each impact energy and their coefficients of determination (R2) are presented in Table 2.

Table 2

Equations representing the relationship between the percentage damage to corn seeds and moisture content for each impact energy

| Impact energy (J) | Equation | R2 |

| 0.1 | 0.996 | |

| 0.2 | 0.986 | |

| 0.3 | 0.985 |

All the indexes are significant at the level of 99.95%.

SD= seed damage (%), M= moisture content (%)

As follows from the relations, the effect of moisture is stronger for the higher levels of energy than in the case of the lower ones (higher values at variable M2).

Effect of impact energy

The results of Duncan’s multiple range tests for comparing the mean values of the damage to corn seeds at different impact energies are shown in Fig. 3 (the mean values at the moisture contents of 7.60, 12.5, 15, 17.5, 20 and 25% and at three replications). It is evident that seed damage increased, as a quadratic function, with increasing impact energy. For all the levels of impact energy, the differences between the mean values of the damage are significant (p=0.05). With increasing the impact of the energy from 0.1 to 0.3 J, the mean value of the damage increased by about 59.75% (from 23.73 to 83.49%). The corresponding value for increasing the impact of the energy from 0.1 to 0.2 J and from 0.2 to 0.3 J was about 40.49 and 19.25%, respectively. Similar results about increasing the seeds damage with impact energy have been reported by other researchers (Khazaei et al., 2008; Shahbazi, 2011; Shahbazi et al., 2011 a and b). Shahbazi et al. (2012) found that increasing the impact energy from 0.05 to 0.1 J caused an increase in the percentage breakage of seeds from 18.68 to 35.21% and from 44.78 to 71.61% for wheat and triticale seeds, respectively.

In Fig. 4, the percentage of damage to seeds is plotted against the energy of the impact. The figure reveals that at all the seed moisture contents considered the seed damage increases as the impact energy increases. Due to the significant interaction effect between impact energy and moisture content, the rates of increase in damage are not the same for all levels of moisture contents. The effect of impact energy on the damage is stronger at lower moisture contents than at higher ones. In Fig.4, the lowest damage among the combinations was found to be 3.36% occurred in the 0. 1J impact energy, with the moisture content of 20%, while the greatest damage was obtained as 100%, occurred in the impact energy of 0.3 J, with the moisture content of 7.6%. At 7.6% seed moisture content, percentage damage increased from 60.79 to 100%, with an increase in the impact energy from 0.1 to 0.3 J.

Figure 3 – Effects of the impact energy on the percentage of damage to corn seeds. Averages with the same letter have no significant difference at the 5% significance level.

Figure 4 – Corn seeds impact damage variation with impact energy for different seed moisture contents

Corresponding percentage damages were from 38.15 to 83.20%, 23.77 to 78.59%, 14.00 to 77.25, 3.36 to 75.99, and from 3.38 to 18.14% for the same energy range, at 12.5, 15, 17.5, 20 and 25% moisture contents, respectively. The seed damage was related to the energy of impact in the range of 0.1 to 0.3 J, by regression analysis. The results showed that the percentage of physical damage to seeds was a quadratic function of the energy of impact, at all the moisture contents considered.

The equations representing the relationship between the percentage damage to seeds (SD, %) and impact energy (IE, J) for each moisture content (M, %) and their coefficients of determination (R2) are presented in Table 3.

Table 2

Equations representing the relationship between the percentage damage to corn seeds and impact energy for each moisture content

| Moisture content (%) | Equation | R2 |

| 7.60 | 0.999 | |

| 12.5 | 0.992 | |

| 15 | 0.997 | |

| 17.5 | 0.999 | |

| 20 | 0.998 | |

| 25 | 0.997 |

All the indexes are significant at the level of 99.5%.

SD= seed damage (%), IE= impact velocity (J)

For the optimum level of moisture content of 20% in Figs. 2 and 4, the percentage damage to seeds were 3.36, 51.33 and 75.99% at impact energies of 0.1, 0.2 and 0.3 J, respectively, shown that at energies lower than 0.1 J, the seed damage is lower than 10%. Based on the above fact, the limitation of impact energy to 0.1 J could be considered in the case of designing or adjusting the threshing and other mechanisms for handling or processing the corn seeds.

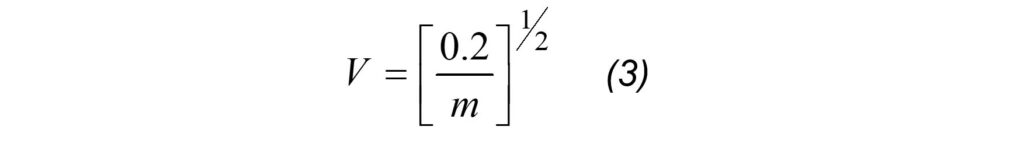

It suggests that the radius and speed of the machine parts should be such that will not allow the impact energy of 0.1 J to be exceeded; higher energy than 0.1 J will damage seeds. However, considering the mass of the seed, m (kg), which absorbs the impact energy, in the machine, the impact velocity, V (m s-1), in such machine to cause the same amount of energy, could be determined:

In this study, the limited impact energy was found to be IE=0.1J, thus the velocity of the machine parts, that subject the seed with the mass of m (kg) to the required impact energy, could be determined:

For the sample seeds used in this study, the mean mass of the seeds, at an optimum moisture content of 20%, found to be 0.000266 kg (data not shown). Thus, substituting the values of IE and m into equation 3, the velocity of impact gives about 27 m s-1.

Based on above results, the best conditions for harvesting and other processing for corn seeds, in which seeds are subjected to impact loads, will be at moisture contents of about 17-20%, with impact energy and velo-city limited to about 0.1 J and 27 m s-1, respectively. These features may be important in the case of selecting the time of harvesting and designing or adjusting the threshing and other mechanisms for handling or processing the seeds, to limit the impact energy and velocity of machine parts to 0.1 J and 27 m s-1, from the viewpoint of minimizing yield losses due to the share of damaged seeds.

Modeling

An empirical relationship was developed utilizing the dependence of

the corn seeds percentage damage (SD, %) on parameters, such as seed moisture content (M, %), impact energy (IE, J), and M×IE as independent variables, with the help of regression techniques.

The relationship is given as follows:

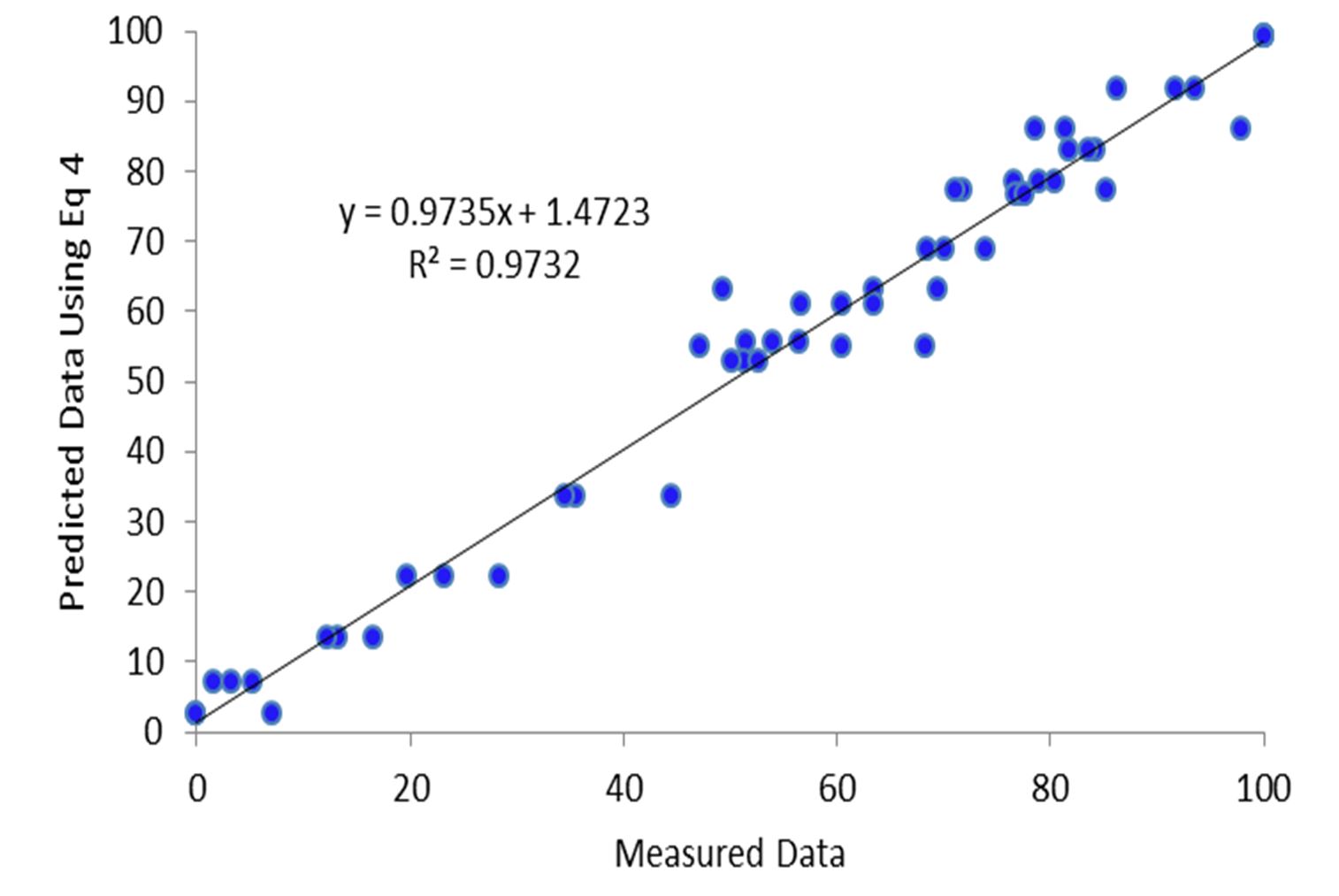

The regression statistics for the model indicated that all terms were significant effects (at the 99.5% level) on the accuracy of the model.

The p-value of predicting equ-ation was <0.0001. The performance of the selected relationship for the prediction percentage of damage to corn seeds due to impact is shown in Fig. 5. This figure shows the predicted percentage of damage data versus the same set of measured data. The scatter plot showed no tendency for the model to under- or over-estimate the predicted percentage of damage data. It is observed that the predictive capability was good and data points were well compressed about the ideal of the unity-slope line selected. The linear adjustment between the observed and estimated values gives a slope practically equal to 1 (Y=0.9735X +1.4723). The resulting correlation coefficient and the p-value were 0.9732 and <0.0001, respectively, for the regression between observed and estimated values (Fig. 5), indicating that the model provided satisfactory results over the whole set of values for the dependent variable.

CONCLUSIONS

The data obtained from this study showed that the significant differences in the susceptibility of corn seeds to impact damages were revealed at different levels of seed moisture content and impact energy.

Impact energy, moisture content, and the interaction effects of these two variables significantly influenced the percentage of physical damage in corn seeds (p<0.01).

It was found that the percentage of damage to seeds was a quadratic function of impact energy. Increasing the impact of the energy from 0.1 to 0.3 J caused an increase in the mean percent physical damage to seeds from 23.73 to 83.49%. To minimize physical damage to corn seeds the im-pact energy should be limited to 0.1 J.

As moisture content increased from 7.60 to 20%, the mean values of damage to seeds decreased by a factor of 1.92, following a quadratic relationship. The optimum level of moisture, where impact damage was minimized, was about 17-20%.

The mechanical damage to corn seeds under impact loading was accurately described by an empirical model composed of moisture content and impact energy.

REFERENCES

ASAE (1988). Moisture measurement – Grain and seeds. Agric.Eng. Yearbook, ASAE, Standard ASAE, 347-352.

Bartsch, J.A., Haugh, C.G., Athow K.L. & Peart, R.M. (1979). Impact damage to soybean seed. ASAE Paper No. 79-3037, St. Joseph, MI: ASAE.

Baryeh, E.A. (2002). A simple grain impact damage assessment device for developing countries. J.Food Eng., 56, 37-42.

Hoki, M. & Pickett. L.K. (1973). Factors affecting mechanical damage of navy beans. Transactions of the ASAE,16(6):1154-1157.

Khazaei J., Shahbazi, F.,Massah, J., Nikravesh, M. & Kianmehr. M. H. (2008). Evaluation and modeling of physical and physiological damage to wheat seeds under successive impact loadings: mathematical and neural networks modeling. J.Crop Sci., 48(4),1532-1544, DOI: 10.2135/cropsci2007.04.0187

Khazaei, J. (2009). Influnce of impact velocity and moisture content on mechanical damage of white kindey beans under impact loadings. Cercetări Agronomice în Moldova, 1(137), 5-18.

Kim, T.H., Opara, L.U., Hampton, J.G., Hardacre, A.K. & MacKay B.R. (2002). The effects of grain temperature on breakage susceptibility in maize. Biosyst.Eng., 82(4), 415-421, DOI: 10.1006/bioe.2002.0094

Oluwole, F.A., Aviara, A. & Haque, M.A. (2007). Effect of moisture content and impact energy on the crackability of sheanut. Agric.Eng.Int.: CIGR Journal, Vol. IX.

Parde, S.R., Kausal, R.T., Jayas, D.S. & White, N.D.G. (2002). Mechanical damage to soybean seed during processing. J. Stored Prod.Res., 38(4),385-394,DOI: 10.1016/S0022-474X(01)00040-6

Shahbazi, F., Analooei, M. & Saffar, A. (2011a). Mechanical damage to pinto bean seeds as affected by moisture content, impact velocity and seed orientation. Int.J.Food Eng.,7(6), DOI: 10.2202/1556-3758.2503

Shahbazi, F. (2011). Impact damage to chickpea seeds as affected by moisture content and impact velocity. Appl.Eng.Agric., 25(7), 771-775, DOI:

10.13031/2013.39557

Shahbazi, F. (2014). Effects of moisture content and impact energy on the cracking characteristics of walnuts. Int.J.FoodEng., 10(1),149-156 , DOI: 10.1515/ijfe-2012-0168

Shahbazi, F., Dolatshah, A. & Valizadeh, S. (2014). Evaluation and modeling the mechanical damage to cowpea seeds under impact loading. Qual. Assur. Saf. Crop, 6(4): 453-458,

DOI: 10.3920/QAS2012.0120

Shahbazi, F., Saffar, A. & Analooei (2011b). Mechanical damage to navy beans as affected by moisture content, impact velocity and seed orientation. Qual.Assur.Saf.Crop., 205-211, DOI: 10.1111/j.1757-837X.2011.00114.x

Shahbazi, F., Dowlatshah, A. & Valizadeh, S. (2012). Breakage susceptibility of wheat and triticale seeds related to moisture content and impact energy. Cercetări agronomice în Moldova, 3(151): 5-13.

Sosnowski, S. & Kuzniar, P. (1999). Effect of dynamic loading on the quality of soybean. Int.Agrophys., 13,125-132.

Sosnowski, S. (2006). Reasons of mechanical damage of bean seeds under dynamic loads. Acta Agrophys.,130: 1-65.

Szwed, G. & Lukaszuk, J. (2007). Effect of rapeseed and wheat kernel moisture on impact damage. Int.Agrophys., 21, 299-304.