Jacob Mayowa Owoyemi, Olasunkanmi Joshua Ogunniyi

ABSTRACT. Concerns about the health and environmental risks linked with the use of preservatives, such as chromate copper arsenate (CCA), zinc chloride, mercuric chloride, and the oil-born preservative creosote, prompted the quest for the use of readily available bitumen as a wood preservative. Using samples that had been processed into dimensions of 20 × 20 × 60 mm, the durability and physical characteristics of Gmelina arborea wood treated with bitumen were evaluated. The samples were dried for 24 hours in an oven set to 103°C and treated with hot bitumen at a melting point of 270°C to ensure the flow and maximum penetration of the bitumen. The density showed mean values of 504.93 and 498.71 kg/m3 for the untreated and treated samples, respectively, with the treated samples recording lower values due to the thermal difference in the density distribution between the untreated and treated wood samples. The average weight loss due to leaching of the untreated and treated wood samples after soaking in cold water and hot water was 3.07% and 0.07%, 1.49% and 1.38% respectively for the treatment. The study confirmed the suitability of using bitumen as a preservative for treating G. arborea wood in an environment with extreme weather conditions without causing serious leaching, thereby exposing the wood to degrading agents.

Keywords: accelerated ageing; bitumen; Gmelina arborea; treated wood; wood preservative.

Cite

ALSE and ACS Style

Owoyemi, J.M.; Ogunniyi, O.J. Accelerated ageing assessment of bitumen as a preservative for the treatment of Gmelina arborea wood. Journal of Applied Life Sciences and Environment 2023, 56 (3), 365-374.

https://doi.org/10.46909/alse-563105

AMA Style

Owoyemi JM, Ogunniyi OJ. Accelerated ageing assessment of bitumen as a preservative for the treatment of Gmelina arborea wood. Journal of Applied Life Sciences and Environment. 2023; 56 (3): 365-374.

https://doi.org/10.46909/alse-563105

Chicago/Turabian Style

Owoyemi, Jacob Mayowa and Ogunniyi Olasunkanmi Joshua. 2023. “Accelerated ageing assessment of bitumen as a preservative for the treatment of Gmelina arborea wood Journal of Applied Life Sciences and Environment 56, no. 3: 365-374.

https://doi.org/10.46909/alse-563105

View full article (HTML)

Accelerated Ageing Assessment of Bitumen as a Preservative for the Treatment of Gmelina arborea Wood

Jacob Mayowa OWOYEMI and Olasunkanmi Joshua OGUNNIYI*

Department of Forestry and Wood Technology, Federal University of Technology Akure, P.M.B. 704, Akure, Ondo State, Nigeria; e-mail: jmowoyemi@futa.edu.ng

*Correspondence: ogunniyiolasunkanmi8@gmail.com

Received: Sep. 06, 2023. Revised: Oct. 23, 2023. Accepted: Oct. 31, 2023. Published online: Nov. 20, 2023

ABSTRACT. Concerns about the health and environmental risks linked with the use of preservatives, such as chromate copper arsenate (CCA), zinc chloride, mercuric chloride, and the oil-born preservative creosote, prompted the quest for the use of readily available bitumen as a wood preservative. Using samples that had been processed into dimensions of 20 × 20 × 60 mm, the durability and physical characteristics of Gmelina arborea wood treated with bitumen were evaluated. The samples were dried for 24 hours in an oven set to 103°C and treated with hot bitumen at a melting point of 270°C to ensure the flow and maximum penetration of the bitumen. The density showed mean values of 504.93 and 498.71 kg/m3 for the untreated and treated samples, respectively, with the treated samples recording lower values due to the thermal difference in the density distribution between the untreated and treated wood samples. The average weight loss due to leaching of the untreated and treated wood samples after soaking in cold water and hot water was 3.07% and 0.07%, 1.49% and 1.38% respectively for the treatment. The study confirmed the suitability of using bitumen as a preservative for treating G. arborea wood in an environment with extreme weather conditions without causing serious leaching, thereby exposing the wood to degrading agents.

Keywords: accelerated ageing; bitumen; Gmelina arborea; treated wood; wood preservative.

INTRODUCTION

Wood is a material of biological origin prone to degradation, and it continues to maintain its prime position as a material for building and other construction applications, including bridges, boardwalks and structures, in waterways and wetlands. The sustainable service life of these applications can be accomplished by treating wood with preservatives (Bernhardt, 2017). To ensure that the fixing and retention in place when splits, abrasions and other in-service defects damage the wood, preservatives can be impregnated into the fibre during pressure treatment to protect the timber.

The wood preservation industry has taken large leaps to develop and produce chemicals that protect wood from microorganisms and weathering degradation with no or low environmental impact (Khademibami and Bobadilha, 2022). When deciding which building materials to use, preserved timber has several intrinsic environmental advantages that should be considered (Allan and Phillips, 2021; Morrell, 2011).

The use of bitumen for treating wood, however, has not received much attention. Nigeria’s 42 billion barrels of known bitumen reserves are dispersed throughout a 120-kilometre “bitumen belt” that connects the country’s middle to its western region (Nigeria First).

Bitumen is a non-crystalline solid or viscous substance with sticky qualities that can be made from petroleum naturally or by refinement. It is a thermoplastic hydrocarbon substance that is either black or dark brown in colour and is produced by processing crude petroleum (Riley, 2004). Bitumen is also used for road building and stone wall waterproofing. Typically, it is heated and kept in a molten condition to make handling easier throughout manufacture, storage, transit and use (Rajib et al., 2021).

The use of wood for different purposes is limited due to its susceptibility to wood-destroying organisms. When in a wet state, wood is easily attacked by biodegrading agents (such as termites, fungi and insects), drastically decreasing its strength properties (Hadi et al., 2021). Testing the durability of wood to be used for different purposes in different intended environments is desirable (McNamara, 1994; Santhakumaran, 1973). Globally, wood users do not appreciate the importance of preservation before utilisation; hence, large quantities of timber are used immediately after conversion from logs, leading to insect attacks and fungal infestation (Dodds et al., 2019). One of the major inhibitions in the processing and utilisation of wood is dimensional instability. Due to the hygroscopic nature of wood, wood in service has the tendency to warp and leach material into the environment. Thus, there is a need to assess Gmelina arborea wood treated with bitumen for permanence since this species is now largely used for all forms of construction due to a decline in the supply of durable wood species from the natural forest.

MATERIALS AND METHODS

Study area

This study was carried out at the Department of Forestry and Wood Technology of the Federal University of Technology Akure, Ondo State, Nigeria. Akure is located at a longitude 5.09°E and latitude of 7.18°N in the southwestern part of Nigeria. Its average annual rainfall is approximately 1524 mm, and its average annual relative humidity is approximately 80%. The temperature ranges from 28°C to 31°C (Ibitolu and Ogunjobi, 2016).

Preparation of wood samples

Gmelina arborea trees were obtained from the Department of Forestry and Wood Technology plantation at the Federal University of Technology Akure. The tree trunk was processed into billets for easy evacuation. At the onset of the study, the processed tree trunk was used for different research, such as drying, termite resistance, ageing test, modification and durability. A total of 20 samples were used for this experiment, and the samples were cut to 20 × 20 × 60 mm for the determination of density, moisture content, leaching and accelerated ageing. All samples were planed to remove rough edges, labelled for easy identification and weighed using a weighing balance. After achieving a steady weight through oven drying at 103°C for 24 hours, the samples were placed in a desiccator to cool to room temperature before being weighed.

Determination of physical properties

The physical properties of Gmelina arborea wood species were determined on defect-free wood samples with a measurement of 20 mm × 20 mm × 60 mm. The samples were weighed and measured to obtain their initial weights and dimensions and oven-dried at a steady temperature of 103 ± 2°C until a constant weight was achieved. The following tests were carried out.

Moisture content

The moisture content was determined by selecting five wood samples randomly and was calculated as one of the basic properties of the wood. The wood samples were weighed to obtain the initial weight (Wg) and final weight (Wo) before and after drying. Calculations were made to determine the wood samples’ moisture content according to ASTM D442-16 (2016) (Equation 1):

![]()

where MC = moisture content, Wg = weight of green samples (g), and Wo = weight of oven-dried samples (g).

Density

The density of the wood samples was determined according to ASTM D2395-14 (2017) (Equation 2):

where M = mass of the oven-dried sample (kg) and V = volume of the oven-dried samples (m3).

Weight loss after cold water leaching

The control and treated samples were immersed in cold water for 72 hours and then oven-dried at a certain temperature. After being dried in the oven, the samples were weighed, and the weight loss was calculated using Equation (3):

where WL = weight loss, C3 = weight of the sample before soaking (g) and C4 = weight of the sample after soaking (g).

Weight loss after hot water soaking

The control and treated wood samples were boiled in hot water for 1 hour and then oven-dried at a constant temperature of 103±2°C until a constant weight was achieved. The samples were then weighed, and weight loss due to leaching was calculated using Equation (4):

![]()

where WL = weight loss, B3 = weight of the sample before boiling (g) and B4 = weight of the sample after boiling (g).

Weight loss due to an accelerated ageing test

An accelerated ageing test was conducted according to Sharman and Vautier (1986). The test samples were soaked in water at room temperature for 48 hours.

The soaked samples were boiled in hot water for 1 hour and force-cooled to a temperature of less than 1°C in the freezer (refrigerator) for 24 hours. The samples were later transferred to an oven and dried at 180°C for 1 hour. The tests were carried out based on standardised procedures, following Falemara et al. (2012).

The samples were weighed, and their weight loss was calculated using Equation (5):

where WL = weight loss, A1 = weight of the sample before the ageing test (g) and A2 = weight of the sample after the ageing test (g)

Determination of the bitumen boiling point

The boiling point of the bitumen was determined by heating it and measuring the temperature when bubbles formed using a thermometer.

Treatment of wood samples

Gmelina arborea wood samples were processed into 20 mm × 20 mm × 60 mm pieces. The treated samples were treated with bitumen, while the untreated samples were used as a control. The bitumen was heated in a metallic pot until it completely melted and flowed easily.

Treatment was performed by dipping the wood samples into a container filled with hot bitumen and leaving them for 24 hours to cool. The solidified bitumen was reheated after 24 hours to ensure easy removal of the wood samples. After treatment, the samples were allowed to drain. The treated samples were weighed, and their percentage of absorption was calculated using Equation (6):

where T3 = weight of the sample after treatment (g) and T2 = weight of the sample before treatment (g).

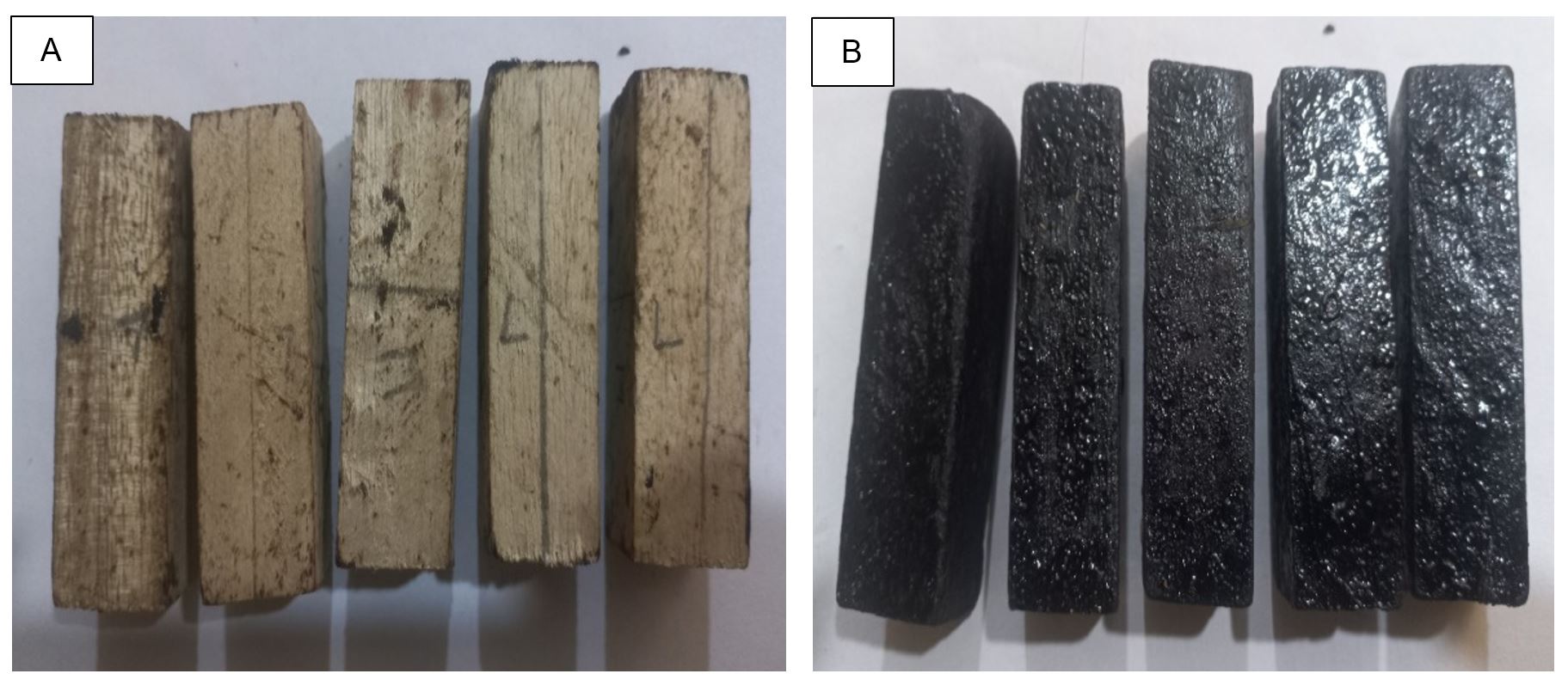

The visual observation of the cross-section of the treated samples, however, showed that there was maximum penetration of bitumen through colour change (Figure 1).

Statistical analysis

The data obtained were analysed using descriptive statistics with the aid of the Statistical Package for Science (SPSS), and analysis of variance (ANOVA) was carried out to test for significant differences.

The graphical representation was carried out using Microsoft Excel.

Figure 1 – A: control Gmelina arborea wood Samples; B: treated Gmelina arborea wood samples

RESULTS AND DISCUSSION

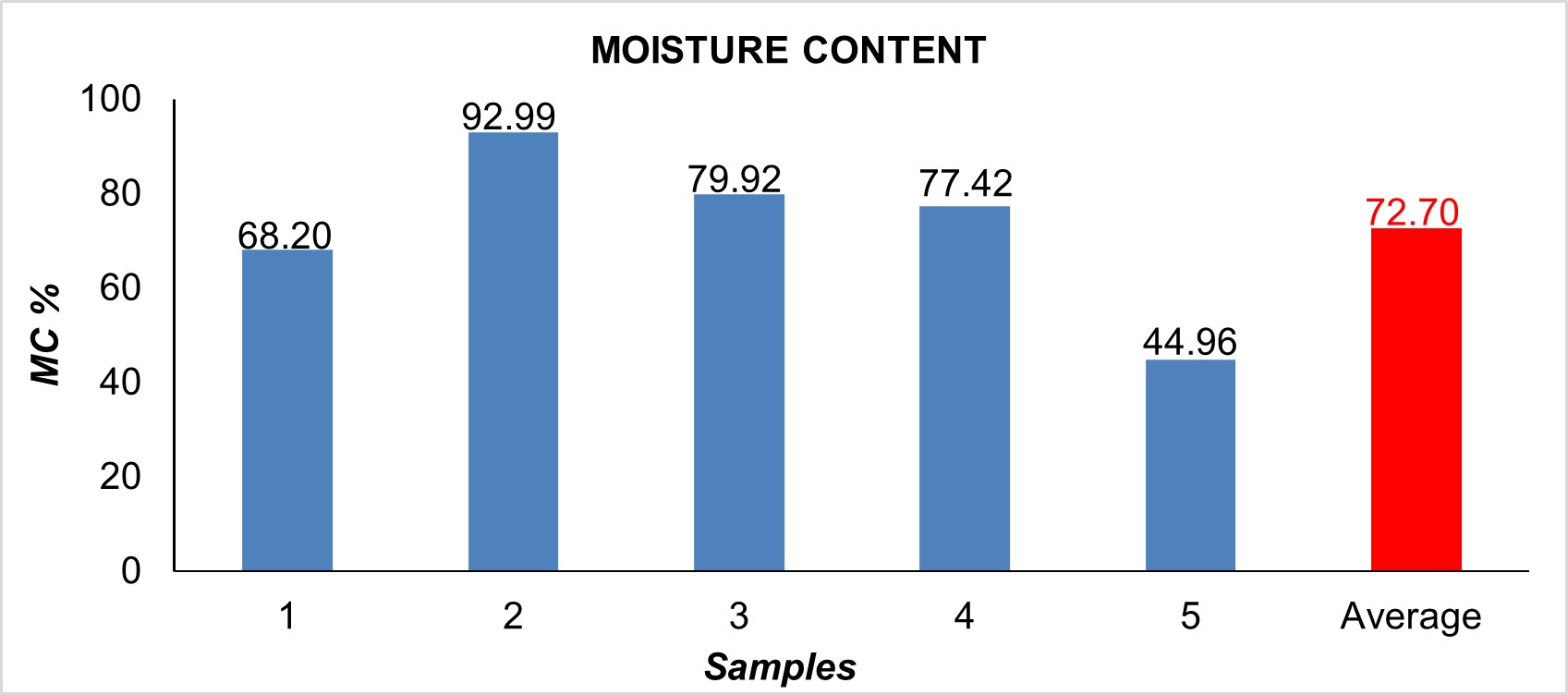

Percentage moisture content of Gmelina arborea

The results in Figure 1 show the percentage moisture content of the selected G. arborea wood samples, which ranged from 44.96 to 92.99%.

When dealing with wood in applications, the moisture content of the wood can have an enormous impact on its quality. Typically, newly sawn wood has moisture levels between 40 and 200%.

According to the relative humidity of the air, the moisture content of wood in typical use ranges from 8 to 25% by weight (Tom, 2018). The existing literature also reports that, through modification involving either chemical treatment or reaction through heat treatment, the dimensional stability of wood can be improved (Owoyemi et al., 2015).

Density

The mean densities of the untreated and treated samples of the Gmelina wood species obtained from this study are summarised in Table 1. The treated wood samples had a density value of 498.71±41.10 kg/m3, which was lower than that obtained for the control wood samples, with a value of 504.93±18.57 kg/m3. Density is a very important variable, with a key influence on every other wood property.

The results of this study revealed that oven-dried G. arborea wood was of low density based on the classification method employed by Falemara et al. (2012).

Wood absorbs moisture faster due to its large pores. This led to the use of bitumen as a preservative for the treatment of G. arborea wood for more stability and resistance against deterioration.

The result of the ANOVA at α = 0.05 presented in Table 2 shows that there was no significant difference in the density distribution between the untreated and treated wood samples, with F (1, 8) = 0.095 and P = 0.766.

Figure 2 – Percentage moisture content of selected Gmelina arborea wood samples before treatment

Table 1

Density distribution of Gmelina arborea wood treated with bitumen

|

Samples |

Density (kg/m3) |

|

Control |

504.93±18.57 |

|

Treated |

498.71±41.10 |

Values are means±SD

Table 2

Analysis of variance for the density of Gmelina arborea treated with bitumen

|

Source of Variation |

Sum of Squares |

df |

Mean Square |

F |

P-value |

Sign |

|

Samples |

96.597 |

1 |

96.597 |

0.095 |

0.766 |

ns |

|

Error |

8134.605 |

8 |

1016.826 |

|

|

|

|

Total |

8231.202 |

9 |

|

|

|

|

df = degrees of freedom; F = F-value; ns = Values greater than 0.05 are not significant

Weight loss after cold water leaching

The findings in Table 3 summarise the results of the weight loss due to the leaching of treated wood samples with bitumen obtained from the study.

The control had a percentage weight loss due to leaching after 72 hours of soaking, with a value of 3.07±0.94%, which was higher than that obtained for the treated wood samples, with a value of 0.07±1.25%.

The ANOVA at α = 0.05 recorded for the cold water leaching of the control and treated wood samples is presented in Table 4, showing a significant difference in the cold water leaching of the control and treated wood samples. From this study, the weight loss due to cold water leaching indicates that wood samples treated with bitumen have a lower rate of leaching, while untreated wood samples have the highest rate of leaching.

Weight loss after hot water leaching

Table 5 presents a summary of the weight loss due to hot water leaching of the control and treated wood samples obtained from the study. The control had a higher average weight loss due to leaching after 1 hour of boiling (1.49±0.69%) than the treated wood samples (1.38±0.56%). There were no significant differences (i.e., P > 0.05) in the mean of the control and hot water treated samples of the Gmelina wood.

The ANOVA at α = 0.05 for hot water leaching of the control and treated wood samples is presented in Table 6, showing no significant difference in the hot water leaching of the control and treated wood samples, with F (1,8) = 0.077 and P = 0.789.

Weight loss after accelerated ageing

The weight loss due to the accelerated ageing test of Gmelina arborea wood samples treated with bitumen is presented in Table 7.

The control wood samples had a higher weight loss due to the ageing test (4.86±0.83%) than the treated wood samples (2.99±0.80%).

Table 3

Weight loss due to leaching of control and treated wood samples obtained after 1 hour of water soaking

|

Samples |

Weight loss (%) |

|

Control |

3.07±0.94 |

|

Treated |

−0.87±1.25 |

Values are mean±SD

Table 4

ANOVA for the weight loss due to leaching of control and treated wood samples obtained after 72 hours of repeated cycles of water soaking

|

Source of Variation |

Sum of Squares |

df |

Mean Square |

F |

P value |

Sig. |

|

Samples |

38.888 |

1 |

38.888 |

31.951 |

0.000 |

* |

|

Error |

9.737 |

8 |

1.217 |

|

|

|

|

Total |

48.625 |

9 |

|

|

|

|

df = degrees of freedom; F = F-value; * = Values less than 0.05 are significant

Table 5

Weight loss due to leaching of control and treated wood samples obtained after 1 hour of water soaking

|

Sample |

Weight loss (g) |

|

Control |

1.49±0.69 |

|

Treated |

1.38±0.56 |

Values are mean±SD

Table 6

ANOVA for the weight loss due to hot water leaching of the control and treated wood samples obtained after 1 hour of boiling

|

|

Sum of Squares |

df |

Mean Square |

F |

P value |

Sig. |

|

Samples |

0.030 |

1 |

0.030 |

0.077 |

0.789 |

ns |

|

Error |

3.145 |

8 |

0.393 |

|

|

|

|

Total |

3.176 |

9 |

|

|

|

|

df = degrees of freedom; F = F-value; ns = Values greater than 0.05 are not significant

There were no significant differences (i.e., P > 0.05) in the mean accelerated ageing between the untreated and treated samples of the wood species, as presented in Table 8.

The accelerated ageing treatment given to the G. arborea wood samples resulted in a significant decrease in the weight of the wood samples. The untreated wood samples had a higher weight loss than the treated wood samples. Accelerated ageing is used to assess the Gmelina arborea wood’s long-term performance, serviceability and durability.

These three phrases all suggest that a design criterion is met or surpassed for a predetermined amount of time in a specific service environment.

Therefore, accelerated ageing has become a method for gathering data on durability, which is the capacity to preserve the use of a product, component, assembly or building over a predetermined period of time (ASTM E 632.0, 1978).

Properties of bitumen and wood species

The boiling point for the bitumen, as shown in Table 9, was 270°C.

Weight loss due to thermal treatment of G. arborea wood

The average weight loss of G. arborea wood due to thermal treatment was 11.48%. The weight of the wood samples that had been preserved revealed a reduction compared to the normal trend associated with other preservative methods. This decrease could be attributed to reactions during the thermal treatment process with bitumen, as the temperature required to heat the bitumen to a flowing consistency necessary for its flow into the wood rose to 270°C, resulting in weight loss. This agrees with the findings of Juanito et al. (2011), who showed that subjecting wood pieces to temperatures between 180 and 260°C for several hours brings about thermal modification of the wood, resulting in weight loss and reduction of strength properties.

Table 7

Weight loss due to accelerated ageing of the control and treated wood samples

|

Samples |

Weight loss (g) |

|

Control |

4.86±0.83 |

|

Treated |

2.99±0.80 |

Values are mean±SD

Table 8

ANOVA table of the weight loss due to accelerated ageing of the control and treated wood samples

|

Source of Variation |

Sum of Squares |

Df |

Mean Square |

F |

P value |

Sig. |

|

Samples |

8.761 |

1 |

8.761 |

13.123 |

0.007 |

ns |

|

Error |

5.341 |

8 |

0.668 |

|

|

|

|

Total |

14.102 |

9 |

|

|

|

|

df = degrees of freedom; F = F-value; ns = Values greater than 0.05 are not significant

Table 9

Properties of bitumen

|

Properties |

Value |

|

Boiling Point |

270oC |

Additionally, Niemz et al. (2010) revealed that high temperatures initiate chemical reactions in the cell walls, which result in the degradation of cellulose and hemicellulose and the modification of lignin, and that equilibrium moisture content is lowered by this type of treatment.

CONCLUSIONS

Wood protection is a major step towards ensuring longevity and sustainability in service. Bitumen has proven potent as a preservative for treating timber used for external applications, such as transmission poles, fence posts, and wharf jetties. For the effective utilisation of wood, this study revealed that bitumen can be employed in the preservation of G. arborea wood.

Therefore, the efficacy of this treatment in improving the commonly available, less durable plantation wood species is a crucial way to lessen the heavy burden placed on forest vegetation. Consequently, a lot of bitumen is available, which should further encourage the use of this preservative to enhance the inherent properties of wood for different construction applications, especially where it will be exposed to extreme weather conditions.

Author Contributions: Conceptualisation (JMO), methodology (JMO, OJO), analysis (JMO), investigation (JMO, OJO), data curation (JMO, OJO), writing (JMO, OJO). All authors declare that they have read and approved the publication of the manuscript in this present form.

Conflicts of Interest: There are no conflicts of interest regarding this article.

REFERENCES

Allan, K.; Phillips, A. Comparative Cradle-to-Grave Life Cycle Assessment of Low and Mid-Rise Mass Timber Buildings with Equivalent Structural Steel Alternatives. Sustainability. 2021, 13, 3401. https://doi.org/10.3390/SU13063401.

ASTM E632.0 (American Society of Testing and Materials). Recommended practice for developing short-term accelerated tests for prediction of the service life of building components and materials; Designation, Part American Society for Testing and Materials, Philadelphia, Pa, 1978.

ASTM D2395-2014. Standard Tests Method for Density and Specific Gravity (Relative Density) of Wood and Wood-Based and Materials. ASTM International, West Conshohocken, PA, 2014.

ASTM D442-2016. Standard Tests Method for Direct Moisture content measurement of Wood and Wood-Based Materials. ASTM International, West Conshohocken, PA, 2016.

Bernhardt Jr, R. Senior Program Manager, Western Wood Preservers Institute, USA, 2017.

Dodds, K.; DiGirolomo, M.; Fraver, S. Response of bark beetles and woodborers to tornado damage and subsequent salvage logging in northern coniferous forests of Maine, USA. Forest Ecology and Management. 2019, 450, 117489. https://doi.org/10.1016/J.FORECO.2019.117489.

Falemara, B.C.; Olufemi, B.; Owoyemi, J.M. Physical properties of Ten selected Indigenous wood species in Akure, Ondo State, Nigeria, Journal of Sustainable Environmental Management. Scientific Journal of Association of Women in Forestry and Environment. 2012, 4, 16-23.

Ibitolu, H.; Ogunjobi, K. ISPRS- International Archives of the Photogrammetry, Remote Sensing and Spatial Information Sciences, Volume XLI-B8, 2016, pp. 897-904.

Juanito, P.J.; Menandro, N.A.; Ramon, A.R.; Ponciano, S.M. “PhysicoMechanical Properties and Durability of Thermally Modified Malapapaya [Polyscias nodosa (Blume) Seem.] Wood. Philippine Journal of Science. 2011, 140, 14.

Khademibami, L.; Bobadilha, G.S. Recent Developments Studies on Wood Protection Research in Academia. Frontiers in Forests and Global Change. 2022, 5. https://doi.org/10.3389/ffgc.2022.793177.

McNamara, W.S. Soil block versus field test for evaluating and standardizing wood preservatives: a commercial view. IRG/WP 94–20024. Stockholm, Sweden: International Research Group on Wood Preservation. 1994, 5 p.

Morrell, J.; Brooks, K.; Davis, C. Managing Treated Wood in Aquatic Environments, Forest Products Society, Chapter 9, 2011. http://preservedwood.org/portals/0/documents/Chapter9_Brooks.pdf

Niemz, P.; Hoffman, T.; Retfalvi, T. “Investigation of Chemical Changes in the Structure of Thermally Modified Wood,” Maderas Ciencia Y Technologia, Universidad del Bio-Bio, 2010, 12, 69-78.

Owoyemi, J.M.; Kayode, J.O.; Olaniran, O.S. Effect of Age on the Natural Resistance of Gmelina arborea Word to Subterranean Termite Attack. Proceedings of 3rd Biennial National Conference of the Forests and Forest Products Society, 2015, pp.108-11.

Rajib, A.; Shariati, S.; Fini, E. The effect of progressive aging on the bond strength of bitumen to siliceous stones. Applied Surface Science. 2021, 550, 149324. https://doi.org/10.1016/J.APSUSC.2021.149324.

Hadi, Y.; Nawawi, D.; Abdillah, I.; Pari, G.; Pari, R. Evaluation of Discoloration and Subterranean Termite Resistance of Four Furfurylated Tropical Wood Species after One-Year Outdoor Exposure. Forests. 2021. https://doi.org/10.3390/F12070900.

Riley, T. “Bitumen Occupational Health – Update on Recent Activities” Proceedings of the 8th Conference on Asphalt Pavements for Southern Africa (CAPSA’04) Sun City, South Africa, 2004, pp. 29-42.

Santhakumaran, L.N. On the natural resistance of Lannea coromande, Tetrameles nudiflora, and Tectona grandis to marine borers in Bombay Harbour. Journal of Timber Development Association of India. 1973.

Sharman, W.R.; Vautier, B.P. Accelerated durability testing of autoclaved wood-fiber-reinforced cement sheet composites. Durability Building Mater. 1986, 3, 255-275.

Tom, L. What does moisture content in wood mean? Delmhorst instrument co. https://www.delmhorst.com/blog/what-does-moisture-content-in-wood-mean. (accessed on 26th December 2018).

Academic Editor: Dr. Isabela Maria Simion

Publisher Note: Regarding jurisdictional assertions in published maps and institutional affiliations ALSE maintain neutrality.