M.M. Rashid, H. Khatun, M.F. Rayhan, M.E.A. Plabon, M.U. Hossain, M.A. Mozid, M.M. Kamal, M.K. Hasan, A. El Sabagh, M.S. Islam

ABSTRACT. Fruits and vegetables are important sources of nutrients for mankind. Among the various fruits available in Bangladesh, mango occupies a vital place in the human nutrition for its delicious taste and higher nutritious value. In this study, five mango varieties, viz. Fazli, Amrupali, Langra, Gopalbogh and Misribogh, were tested to evaluate the quality of these mango varieties available in Northern Bangladesh. Physiochemical characteristics, including moisture, ash, total carbohydrates, total solids, total soluble solids (TSS), pH, acidity, total sugars and ascorbic acid contents were evaluated. The results showed that there were significant (p< 0.05) differences among mangoes of all varieties for physicochemical parameters. In case of proximate composition, the mango variety Amrupali showed the highest ash content (2.34±0.15) and fat content (1.18±0.13). Protein content (0.94±0.12) and total fiber (2.67%) content was shown to be the highest by Gopalbogh and Misribogh, respectively. The selected mango varieties contained TSS of 12.87~20.55oBrix, pH of 4.45~4.67, titrable acidity of 0.07~0.42%, reducing sugar of 8.40~15.43%, non-reducing sugar of 9.24~10.48%, and total sugarof 18.88~25.12%. The study findings would be helpful for the consumers, dietitian and industry policymakers.

Keywords: mango; proximate analysis; quality traits.

View full article (HTML)

Comparative study on physicochemical properties of selected mango (Mangifera Indica L.) varieties in northern Bangladesh

M.M. Rashid1, H. Khatun1, M.F. Rayhan2, M.E.A. Plabon3, M.U. Hossain4, M.A. Mozid5, M.M. Kamal6, M.K. Hasan7, A. El Sabagh8,*, M.S. Islam7,*

1Department of Food Science and Nutrition, Hajee Mohammad Danesh Science and Technology University, Bangladesh

2Faculty of Agriculture, Hajee Mohammad Danesh Science and Technology University, Bangladesh

3Department of Food Engineering & Technology, Hajee Mohammad Danesh Science and Technology University, Bangladesh

4Department of Applied Chemistry and Chemical Engineering, University of Dhaka, Bangladesh

5Department of Physiotherapy, University of Dhaka, Bangladesh

6Department of Food Processing & Preservation, Hajee Mohammad Danesh Science and Technology University, Bangladesh

7Department of Agronomy, Hajee Mohammad Danesh Science and Technology University, Bangladesh

8Department of Agronomy, Faculty of Agriculture, Kafrelsheikh University, Egypt

*E-mail: shahid_sohana@yahoo.com; aymanelsabagh@gmail.com

Received: June 22, 2018. Revised: Sept. 27, 2018. Accepted: Nov. 19, 2018. Published online: Oct. 10, 2019

ABSTRACT. Fruits and vegetables are important sources of nutrients for mankind. Among the various fruits available in Bangladesh, mango occupies a vital place in the human nutrition for its delicious taste and higher nutritious value. In this study, five mango varieties, viz. Fazli, Amrupali, Langra, Gopalbogh and Misribogh, were tested to evaluate the quality of these mango varieties available in Northern Bangladesh. Physiochemical characteristics, including moisture, ash, total carbohydrates, total solids, total soluble solids (TSS), pH, acidity, total sugars and ascorbic acid contents were evaluated. The results showed that there were significant (p< 0.05) differences among mangoes of all varieties for physicochemical parameters. In case of proximate composition, the mango variety Amrupali showed the highest ash content (2.34±0.15) and fat content (1.18±0.13). Protein content (0.94±0.12) and total fiber (2.67%) content was shown to be the highest by Gopalbogh and Misribogh, respectively. The selected mango varieties contained TSS of 12.87~20.55oBrix, pH of 4.45~4.67, titrable acidity of 0.07~0.42%, reducing sugar of 8.40~15.43%, non-reducing sugar of 9.24~10.48%, and total sugarof 18.88~25.12%. The study findings would be helpful for the consumers, dietitian and industry policymakers.

Keywords: mango; proximate analysis; quality traits.

INTRODUCTION

Mango (Mangifera indica L.) is an economical crop in many countries, especially India, Bangla-desh, Pakistan, Philippines, Indonesia, Malaysia, Thailand, Myanmar and Srilanka, etc. (Islam et al., 2013). Mango ranks the third among the tropical fruits in the world with a complete production of 47.13 million tons (FAO, 2017), whereas Bangladesh produced 1.16 million tons (BBS, 2017). Among the fruits, mango secures 1st place regarding the area, and third in terms of production in Bangladesh (BBS, 2017). Mango is now recognized as one of the best fruits of all indigenous fruits due to its excellent flavor, attractive fragrance, and beautiful shades of color, deli-cious taste and high nutritive value. Several hundred varieties are grown in the Indian sub-continent, but a few specific varieties are commercialized according to prefe-rences of different regions of the countries. About 250 varieties of mangoes are grown in Bangladesh (Shafique, 2006).

Besides, having the delicious taste, exotic flavor, and many shaded colors, it is a decent supplier of nutria-tion’s. As a supply of nutrient, mango occupies a considerable quantity of antioxidant, β-carotene, and dietary fiber further as soluble sugar and varied minerals (Pal, 1998). Among the main constituents of this fruit, carbohydrate and acid contribute a great deal to the food value of the fruit. High production of mango has been accompanied by high post-harvest loss of mango because of excess fruits in the market during the peak seasons. Post-harvest value addition technology would reduce these losses giving farmer high return for their crop.

Mango is consumed world wide as either whole fruit, fresh-cut produce, processed juice, pickle, dried fruit, chutney, pulp, paste, puree, jam, slices in brine or flour (Evans, 2008; Ntombela, 2012; IIRR, 2006). The stability of fresh-cut or dried mango during processing and storage de-pends primarily on fruit composition, ripening stage and certain post-harvest processing treatments. Fruits with high solid content are needed for mango puree, jam, pulp or paste to increase product yield.

Increased total soluble solids (TSS) content is important to juice and concentrates manufacturers. Some level of firmness is required for high consumer appreciation of the fresh-cut product. The flavor and color charac-terristics are virtually important to all end users of mango fruit. Fresh-cut mango was reported as a potential for the new product to the fresh produce sector (Djioua et al., 2010). However, during fresh-cut processing, the mango fruit experiences softening and decrease in overall appearance because of tissue browning on the cut surface (Plotto et al., 2004).

It is interesting to compare the quality parameters of mangoes of different varieties with other types knowing the potential of other alternative mango cultivars. This can open a new perspective to the farmers and local industries and will also benefit the consumer by offering a great source of vitamin A.

Therefore, it is necessary to study the nutritional characteristics of different mango variety available in Bangladesh. This will help the consumers to choose the right variety with more nutritional value, as well as the processed food manufacturers to predict the suitable variety for different mango products. Therefore, this study was undertaken to analyze the physicochemical properties of selected mango varieties of northern Bangladesh.

MATERIALS AND METHODS

Experimental site

The experiment was conducted atthe Food and Process Engineering Lab-1 and Laboratory of Agricultural Chemistry, Hajee Mohammad Danesh Science and Technology University, Dinajpur, Bangladesh.

Sample collection

Fresh and mature different mango varieties, viz. Fazli, Langra, Amrupali, Gopalbogh and Misribogh, were collected from Rajshahi district on 01 July, 2017 (during harvesting time) (Fig. 1). These mango samples were brought into the laboratory and stored in a refrigerator at 3-5oC for further use.

Proximate analysis

The proximate chemical composi-tion represents the gross content of important chemical constituents, such as moisture, fat, protein, ash, total carbohydrate. The study of the proximate composition serves as an important base to study the nutritive quality of mango.

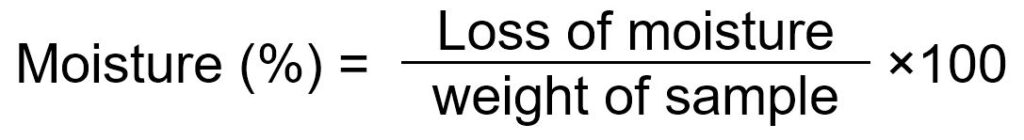

Determination of moisture content

The moisture content of mango pulp was determined in accordance to the moisture measurement method of AOAC (2000). About 10 g of mango sample was taken in previously dried (1 h at 100°C) empty Petri dishes. Then, the Petri dishes with samples were dried in an air oven at 100-105°C for 24 hrs or more till constant weight. After drying, the Petri dishes was removed from the oven and cooled in desiccators and weighed soon after reaching room temperature. The losses are taken as the moisture loss of the sample. From these weights the percent of moisture in the samples were calculated as follows:

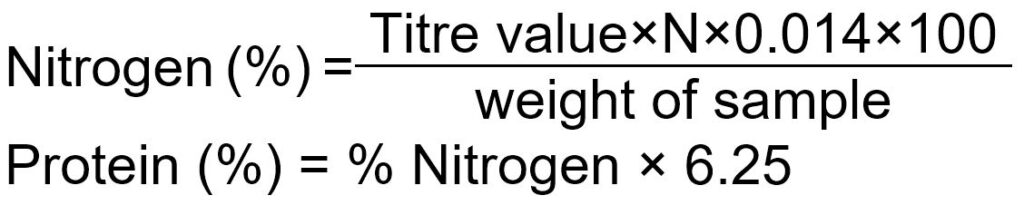

Estimation of protein

The modified Kjeldahl method is used to determine the total nitrogen consisting of organic and ammonium forms. It is a wet oxidation procedure, where the complex form of nitrogen in plant protein is converted to nitrogen.

Procedure

Digestion

Previously oven-dried sample of 1g was taken in a digestion flask. Potassium sulphate (K2SO4) of 10 g, copper sulphate (CuSO4) of 0.1 g, selenium powder of 1g and concentrated H2SO4 of 25 ml was added to it and heated until the solution became clear. Then the flask was cooled.

Distillation

After digestion 300 ml distilled water and 125 ml 40% NaOH solution was added to it. Then the flask was attached quickly to the distillation set and heated the flask continuously. In the meantime, a 250 ml conical flask (containing 25 ml of 4% boric acid and 4-5 drops of mixed indicator) was placed at the zet of the condenser. Exact 150 ml distillate was collected and was titrated with 0.2 N H2SO4 solution.

Titration

The micro burette was filled with 0.01 N HCl until the blue color disappears. The blank distillation was carried out and titrated.

Here, 6.25 is the protein factor for plant samples.

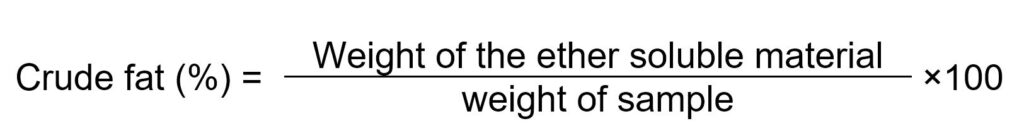

Determination of fat

The crude fat content of the samples was measured according to the method AOAC (2000). Dried mango slices of 5 g were transferred into a thimble and plugged the top of the thimble with fat-free cotton. The thimble was dropped into the fat extraction tube of a soxhlet apparatus. The bottom of the extraction tube was attached to soxhlet flask. Approximately 75 ml or more of anhydrous ether was poured into the flask. The top of the fat extraction was attached to the condenser. The sample was extracted for 6 h at 50°C, so that the ether which volatilized was condensed and dropped continuously upon the sample without any appreciable loss.

At the end of the extraction period, the thimble was removed from the apparatus and most of the ether was distilled off by allowing it to collect in the soxhlet tube. The ether was poured off when the tube was nearly full. When the ether was reached to a small volume, it was poured into a small, dry (previously weighed) beaker through a small funnel containing plug cotton. The flask was rinsed and filtered thoroughly using ether. The ether was evaporated on a steam bath at low heat, it was then dried at 100°C for 1 h, cooled and weighed. The difference in the weights was the ether-soluble material present in the sample.

The percent of crude fat was expressed as follows:

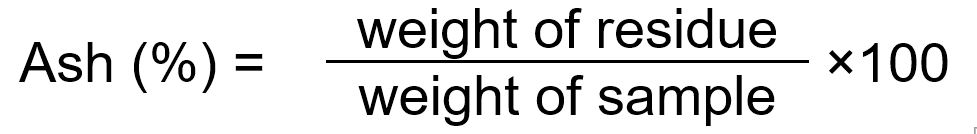

Determination of ash

Total ash content was determined by adopting the method of AOAC (2000). A quantity of 5 g of each mango samples were weighed and taken in dry, clean porcelain dishes. Hot air oven method was applied to remove the moisture. Then, the samples were burnt on an electric heater. This was done to avoid the loss of sample in the muffle furnace under higher temperature. Then the samples were transferred into the muffle furnace and burnt at 550°C temperature for 4-6 hrs and ignited until light gray ash resulted (or to constant weight). The samples were then cooled in desiccators and weighed. The ash content was expressed as:

Determination of total carbohydrate

The total carbohydrate of the samples was determined as the total carbohydrate by difference, which is by subtracting the measured moisture, ash, fat, and protein from 100 (Pearson, 1970).

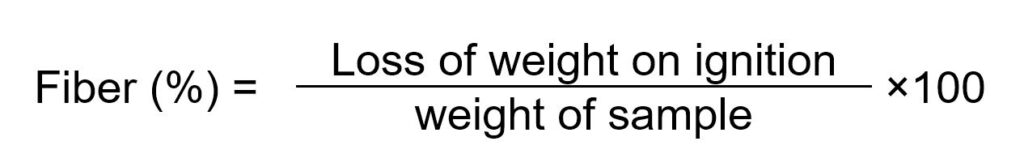

Determination of fiber content

The crude fiber was analyzed by adopting the procedure mentioned by AOAC (2000). A quantity of 5 g sample was used to determine crude fiber of mango samples.

The sample was boiled for 30 min in 200 ml of 1.25% H2SO4 and then filtered and washed. Then the sample was again boiled in 200 ml of 1.25% NaOH for 30 min and then filtered and washed.

The resultant residue was dried at 110ºC for 2 hrs and weighed. The dried residue was ignited at 550±15ºC, cooled and reweighed. The crude fiber was calculated according to the following expression:

Determination of pH

Digital pH meter (HANNA, pH-211) meter was used to determine the pH value of the sample by performing two-point calibrations (with buffer 7.0 and buffer 4.0) before measuring the samples pH value.

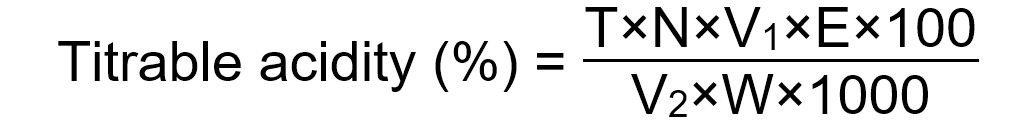

Determination of titrable acidity

The method suggested by AOAC (2000) was followed for the estimation of titrable acidity.

A quantity of 10 ml of the sample was taken in a conical flask; 2-3 drops of phenolphthalein indicator were added to it and titrated with standard NaOH solution from burette. At the end point, pink color appeared.

where, T = Titre value, N = Normality of NaOH, V1 = Volume made up, V2 = Volume of extract (used), E = Equivalent weight of alkali, W = Weight of sample.

Determination of total soluble solids (TSS)

The total soluble solid was determined using a laboratory scale digital refractometer (Type ATAGO, Model-9099).

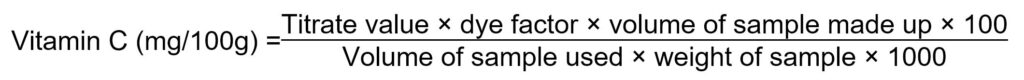

Determination of vitamin C

Ascorbic acid was determined following the method of Ranganna (1979). A quantity of 10 g of fruit sample blended with about 50 ml metaphosphoric solution then it was filtered with a white thin cloth, then it was transferred in a 100 ml volumetric flask and volume up to the mark with the metaphosphoric acid solution. Fruit sample of 10 ml was taken in a conical flask and titrated with dye solution from the burette.

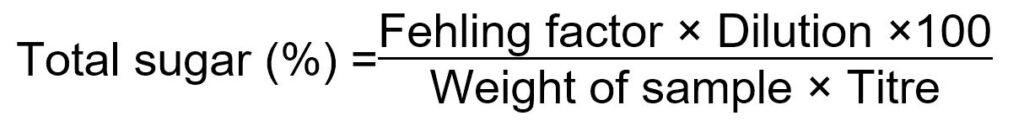

Estimation of total sugars

An aliquot of 50 ml of the clarified, de-leaded filtrate was pipetted to a 100 ml volumetric flask, added 5 ml conc. HCl and allowed to stand at room temperature 24 hrs. It was neutralized with conc. NaOH solution, followed by 0.1 N NaOH solution. The volume was made upto the mark and transferred to 50 ml burette having an offset tip and performed the titration on Fehling’s solution, similar to the procedure described in the determi-nation of reducing sugar (AOAC, 2000).

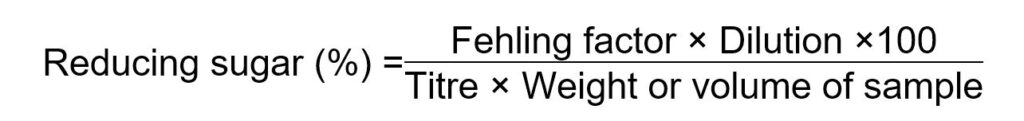

Estimation of reducing sugars

It was determined according to the method described by Haque et al. (2009) and Santini et al. (2014) with slight modification. A quantity of 20 g of the mango pulp was crushed in a mortar and pestle then transferred in a 200 ml volumetric flask. The volume was adjusted to 150 ml by adding purified water. After a few minutes to allow the sugar dissolution, 10 ml of lead acetate solution and the minimum amount of potassium oxalate solution were added. The volume of the resulting solution was adjusted to 200 ml, and the solution shaken, filtered and transferred in a burette for the titration. A quantity of 5 ml of Fehling solution A, 5 ml of Fehling solution B, and 40 ml of purified water were transferred to a flask. The solution was heated up to boiling point and that was added drop by drop till the nearly complete de-coloration of the Fehling reagent. Two drops of methylene blue were added, and the boiling continued for 3 min. The solution from the burette was added until the blue coloration of the indicator disappeared and the solution turned into a red color. Reducing sugar was calculated using the following equation:

Estimation of non-reducing sugars

Non-reducing sugar (%) = % total sugar – % reducing sugar

Statistical analysis

All determinations were done in triplicate and mean ± standard deviation (SD) values were calculated. A commercial software program (SPSS 20.0, SPSS Inc.) was used to perform statistical analyses. Data were assessed by analysis of variance (ANOVA). Duncan’s multiple range test (DMRT) was used to separate means. Significance was accepted at the probability of p< 0.05 throughout the analysis.

RESULTS AND DISCUSSION

Proximate composition of different mango varieties

Moisture content

The moisture content of different mango varieties differed significantly (p< 0.05), as shown in the Table 1. Moisture content was observed more than 70% in all varieties. However, the highest and the lowest moisture content were found in Fazli (88.26%) and Amrapali (72.83%), respectively. The results are in agreement with the findings of Ueda et al. (2000) and Haque et al. (2009), who reported that most fruits are composed of 70 to 90% of water.d be run.

Table 1

Proximate composition of different mango varieties

|

Composition |

Mango varieties |

||||

|

Fazli |

Amrupali |

Langra |

Gopalbogh |

Misribogh |

|

|

Moisture (%) |

88.26 ± 1.34a |

72.83 ± 2.95d |

77.23 ± 1.74c |

82.52± 1.38b |

79.42 ± 1.96c |

|

Ash (%) |

1.97± 0.12a |

2.34± 0.15a |

2.11± 0.07a |

2.20± 0.17a |

2.09 ± 0.19a |

|

Protein (%) |

0.43± 0.08b |

0.53 ± 0.04b |

0.94 ± 0.12a |

0.78± 0.08a |

0.58± 0.07b |

|

Fat (%) |

0.40 ± 0.02c |

1.18 ± 0.13a |

0.11 ± 0.04e |

0.54 ± 0.02b |

0.21 ± 0.04d |

|

Carbohydrate (%) |

8.94 ± 0.13e |

23.12 ± 0.24a |

19.61 ± 0.11b |

13.96± 0.16d |

17.70 ± 0.14c |

|

Values are mean ± standard deviation of three replicates. a-eDifferent superscript alphabets in each row indicate significant difference (P< 0.05) among the mango varieties. |

|||||

Ash content

Table 1 represents the ash content of different mango varieties. The results showed that ash content was not varied significantly (p> 0.05) among the mango varieties. The highest ash content (2.34%) was recorded in Amrupali variety, followed by Gopalbogh (2.20%), Langra (2.11%), Misribogh (2.09%) and Fazli (1.97%). Regarding ash content, Gardner et al. (1939) reported that the total content of mineral salt as ash infruits varied from 0.2 to 1.5%, which is lower than our observed findings.

Almost similar results were also reported by Akhtar et al. (2010).

Protein content

The protein content of different mango varieties has been presented in the Table 1. Significant (p< 0.05) differences regarding the protein content among mango varieties were found in this study. The highest value of protein (0.93%) was found in Langra variety, followed by Gopalbhog (0.78%), whereas the lowest value (0.43%) was found in Fazli variety. Gopalan et al. (1993) have been reported that maximum protein content in the different varieties of tropical fruits varies from 0.4 to 0.8%. Ara et al. (2014) reported that protein content varied between 0.07 to 0.26 % depending on the mango varieties.

Fat content

The total fat ranged from 0.11 to 1.18% (Table 1), which was found to be varied significantly (p< 0.05). Nonetheless, the variety Amrupali showed the highest total fat content (1.18 %) and Langra was found with the lowest amount (0.11 %) of the fat content. It was reported that usually fat content of different fruits is not greater than 1% (Norman, 1976), which supports our findings.

Total carbohydrate content

Generally, carbohydrate of fruit is less concentrated than cereals because of their high water content. A fruit rich in carbohydrate provides a high amount of energy. In this study, the total carbohydrate content was ranged from 8.94 to 23.12% (Table 1), which was found to be varied significantly (p< 0.05) among the mango varieties. Since, carbohydrate was calculated by subtracting the percent moisture, ash, protein and fat from 100%, so its content is totally dependent on the content of others components.

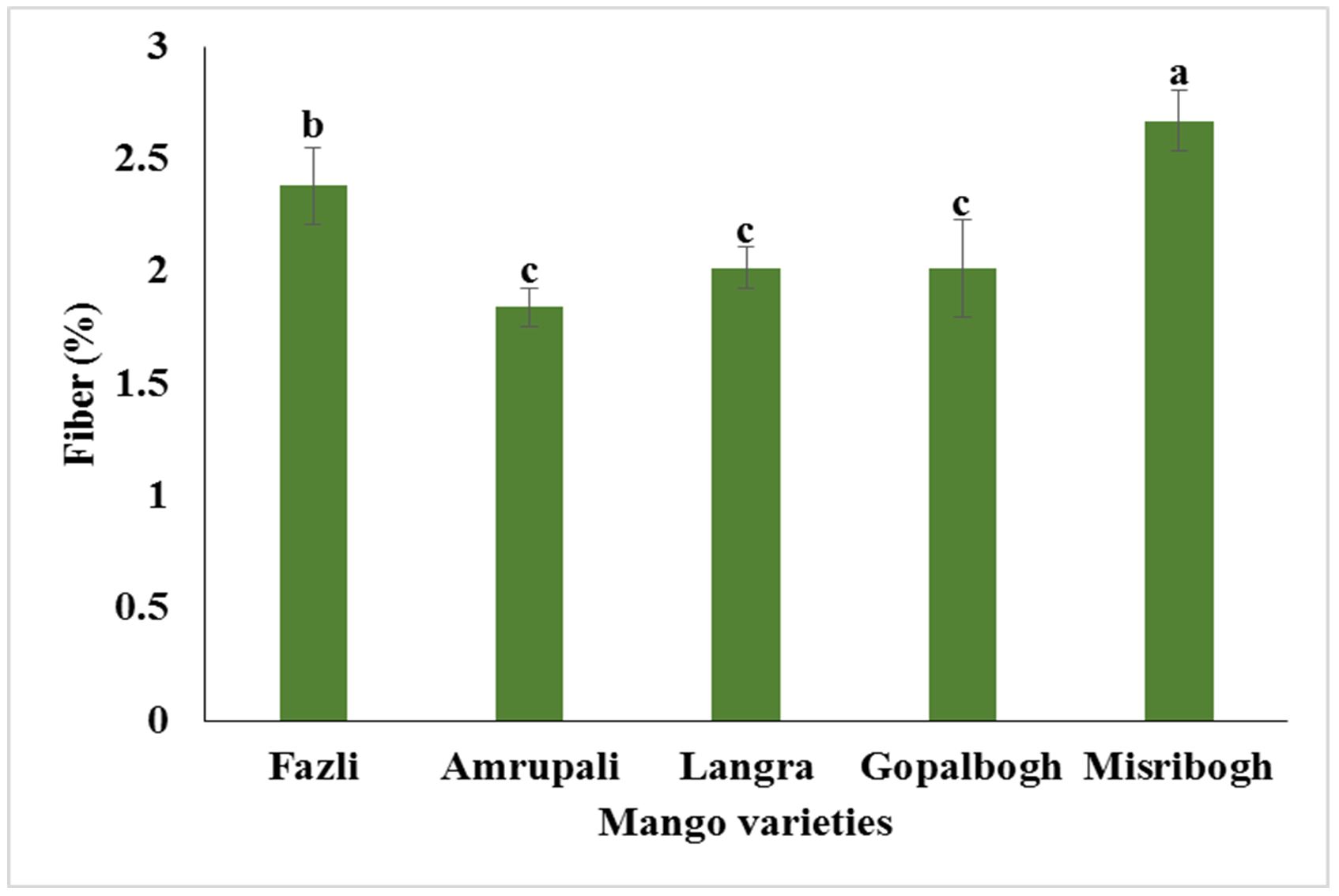

Total fiber content

Results obtained for total fiber content of different mango variety are presented in Fig. 2. The total fiber of mango variety ranged from 1.84 to 2.67%, which were found to vary significantly (p≤ 0.05) among the mango varieties. Nonetheless, the highest fiber content was reported in Misribogh, while the lowest in Amrupali variety.

Biochemical properties of different mango varieties

Total soluble solids

Total soluble solids (TSS) content also differed significantly (p< 0.05) and found to range between 12.87 to 20.55o Brix, being maximum in the Amrupali and it was minimum in the Misribogh. These findings are similar to the reports of previous literature (Akhter et al., 2010). The TSS is directly correlated with the acidity of the fruit. Generally, the acidity of fruit decreases and the TSS increase during maturity and ripening stage of fruit (Padda et al., 2011; Sajib et al., 2014).

pH and titrable acidity

The pH value is an important quality parameter for fruits and vegetables since the growth of micro-organisms highly influenced by its value. This study revealed that significant (p< 0.05) difference of pH existed in different mango varieties (Table 2), which ranged from 4.45 to 4.67. The acidity of this study varied from 0.07 to 0.42% (Table 2), which was found to be remarkably different from each other. However, the highest acidity value was found in the Fazli variety, while the lowest value was found in the Misribogh variety (Table 2).

Higher pH of 4.2 to 5.7 and lower acidity of 0.05 to 0.22% were recorded in the mango varieties grown in Mediterranean subtropical climate, as reported by Pleguezuelo et al. (2012). It was also observed that pH and titrable acidity of 3.35 and 0.68% were obtained in the Langra and 3.75 and 0.63% in Chausa, respectively (Akhter et al., 2010). Hamdard et al. (2004) also reported that acidity varies from 0.25 to 0.60%. The variation of pH and titrable acidity values of mango varieties, as well as mango products, were due to the ripening and the storage of mango as reported by Prusky et al. (1993).

Table 2

Total soluble solid (TSS), pH, titrable acidity, reducing sugar, non-reducing sugar and total sugar of different mango varieties

|

Composition |

Mango varieties |

||||

|

Fazli |

Amrupali |

Langra |

Gopalbogh |

Misribogh |

|

|

Total soluble solids (oBrix) |

18.11 ± 0.49b |

20.55 ± 1.68a |

15.54± 0.16c |

14.68±0.20c |

12.87±4.40d |

|

pH |

4.67 ± 0.09a |

4.50 ± 0.12c |

4.45 ± 0.00d |

4.56±0.01bc |

4.60 ± 0.07b |

|

Acidity (%) |

0.42 ± 0.02a |

0.20 ± 0.03b |

0.14 ± 0.01c |

0.10 ± 0.01d |

0.07 ± 0.00e |

|

Reducing sugar (%) |

10.39 ± 0.54b |

15.02± 0.31a |

8.40 ± 0.50c |

15.43±0.81a |

14.92±0.14a |

|

Non-Reducing sugar (%) |

10.11±0.60ab |

12.54±0.71ab |

10.48±0.76a |

9.24±0.60b |

10.20±0.19ab |

|

Total sugar (%) |

20.49 ± 0.48a |

27.55±0.95ab |

18.88±0.31d |

23.67±0.48b |

25.12 ± 0.06a |

|

Values are mean ± standard deviation of three replicates. a-eDifferent superscript alphabets in each row indicate significant difference (p< 0.05) among the mango varieties. |

|||||

Sugar content

Reducing sugar

Table 2 shows the variationof the reducing sugar content among the mango varieties. The reducing sugar ranged from 8.40 to 15.43%, and the highest content was recorded in the Gopalbogh (15.43%), followed by the Amrupali (15.02%), Misribogh (14.92%), Fazli (10.39%) and Langra (8.40%) variety. These values are similar to the content of reducing sugar for various mango varieties reported by Ara et al. (2014).

Non-reducing sugar

Non-reducing sugar content of different mango varieties was found to be significantly (p< 0.05) different (Table 2). However, the highest non-reducing sugar (12.54%) was recor-ded in the Amrupali, followed by the Langra variety (10.48%), Misribogh (10.20%), Fazli (10.11%), and Gopalbogh (9.24%) varieties.

Total sugar

The total sugar contents of different mango varieties are presented in the Table 2. It was observed that total sugar content was found to be varied significantly (p< 0.05) among the varieties and ranged from 20.49 to 27.55 % (Table 2). However, the highest sugar was observed in the Amrupali variety, while the lowest was found in the Fazli variety.

CONCLUSIONS

Results of this study revealed that, high amount of moisture was found in Fazli variety, while the variety Amrapali contains high ash, fat and carbohydrate hence provides more energy. The variety Langra contains the highest amount of protein and non-reducing sugar, and the variety Gopalbogh contains high reducing sugar. The variety Misribogh contains high amount of fiber and total sugar, whereas the Amrupali variety contains high total soluble solids. pH and acidity was high in the Fazli variety.

Finally, nutritional status of popular five mango varieties of Bangladesh were systematically addressed and recommended their nutritional parameters, which will help the consumers, dietitian and industry policy makers. Sofar we know, this type of work has partially been done in Bangladesh.

Acknowledgments. The authors would like to acknowledge to Dr. Anwara Akter Khatun and Md. Shihabul Aowal, Assistant Professor, Department of Food Science and Nutrition, Hajee Mohammad Danesh Science and Technology Uni-versity (HSTU), Dinajour, Bangladesh. The authors also thank to Mr. Wadud Hossain, Laboratory Attendant, Depart-ment of Agricultural Chemistry, HSTU, Bangladesh, for his help in the experimentation.

REFERENCES

Akhtar, S., Naz, S., Sultan, T.M., Mahmood, S., Nasir, M. & Ahmad, A. (2010). Physicochemical attributes and heavy metal content of mangoes (Mangifera indica L.) cultivated in different regions of Pakistan. Pak.J.Bot., 42(4): 2691-2702.

AOAC (2000). 17th edition. Official method 920. 183 (b) sugars (reducing sugar) in Honey/ I.S.I. Hand book of Food Analysis (part 2) – 1984, p. 36.

Ara, R., Motalab, M., Uddin, M.N., Fakhruddin, A.N.M. & Saha, B.K. (2014). Nutritional evaluation of different mango varieties available in Bangladesh. Int. Food Res.J., 21(6): 2169-2174.

BBS (2017). Yearbook of agricultural statistics of Bangladesh. Bangladesh Bureau of Statistics, Ministry of Planning, Dhaka, Bangladesh, p. 124.

BBS (2017). Yearbook of agricultural statistics of Bangladesh. Bangladesh Bureau of Statistics, Ministry of Planning, Dhaka, Bangladesh, p. 124.

Djioua, T., Charles, F., Freire, M.Jr., Filgueiras, H., Ducamp-Collin, M.N. & Sallanon, H. (2010). Combined effects of postharvest heat treatment and chitosan coating on quality of fresh-cut mangoes (Mangifera indica L.). Int.J.Food Sci.Technol., 45: 849-855, DOI: 10.1111/j.1365-2621.2010.02209.x

Evans, E.A. (2008). Recent trends in world and U.S. mango production. Trade and Consumption, IFAS, Extension Paper FE718, Univ. of Florida, USA, p. 7.

FAO (2017). FAO production yearbook. Food and Agriculture Organization Rome, Italy, 56: 145-146.

Gardner, V.R., Bradford, F.C. & Hooker, H.D. (1939). The fundamentals of fruit production. McGraw-Hill, New York, USA., pp. 159-172.

Gopalan, C., Rama, S.B.V. & Balasubra, S.C. (1993). Nutritive value of Indian foods. 2nd Edition. Indian Council of Medical Research, Hyderabad.

Hamdard, M.S., Rafique, M.R. & Farroq, U. (2004). Physico-chemical charac-teristics of various mango, Mangifera indica L. varieties. Journal of Agric.Res., Pakistan, 42(2): 191-199.

Haque, M.N., Saha, B.K., Karim, M.R. & Bhuiyan, M.N.H. (2009). Evaluation of nutritional and physico-chemical properties of several selected fruits in Bangladesh. Bangladesh Journal of Scientific and Industrial Research, 44(3): 353-358, DOI: 10.3329/bjsir. v44i3.4410

IIRR (International Institute of Rural Reconstruction) (2006). Report of International Institute of Rural Reconstruction. 40 Exchange Pl #1205, New York 10005, USA.

Islam, M.K. (2013). Response of mineral constituents and storability of the postharvest mango (Mangifera indica L.) to different storage treatments. J. Environ. Sci. Nat. Resour., 6(1): 69-77, DOI: 10.3329/ jesnr.v6i1.22043

Islam, M.K., Khan, M.Z.H., Sarkar, M.A.R., Yeasmin, S., Ali, M.K. & Uddin, M.H. (2013). Postharvest quality of mango (Mangifera indica L.) fruit affected by different levels of gibberellic acid during storage. Malaysian J. Analyt.Sci., 17(3): 499-509.

Norman, N. (1976). Food science, 2nd Edition, The Avi Publishing Compa-ny, INC-Westport, Connecticut.

Ntombela, S. (2012). South African fruit trade flow markets. Economic Research Center, National Agricul-tural Marketing Council, Issue no. 6.

Padda, M.S., Amarante, C.V.T., Garcia, R.M., Slaughter, D.C. & Mitchama, E.J. (2011). Methods to analyze physico-chemical changes during mango ripening: a multivariate approach. Postharvest Biol.Technol., 62: 267-274, DOI: 10.1016/j.posthar vbio.2011.06.002

Pal, R.K. (1998). Ripening and rheological properties of mango as influenced by ethereal and carbide. J.Food Sci.Technol., 35(4): 358- 360.

Pearson, D. (1970). The chemical analy-sis of foods. 7th Edition, Churchill Lavingstone, New York, USA.

Pleguezuelo, C.R.R., Zuazo, V.H.D., Fernandez, J.L.M., Tarifa, D.F. (2012). Physico-chemical quality parameters of mango (Mangifera indica L.) fruits grown in a Mediterranean subtropical climate (SE Spain). J.Agric. Sci.Technol., 14: 365-374.

Plotto, A., Goodner, K.L., Baldwin, E.A., Bai, J., Rattanapanone, N. (2004). Effect of polysaccharide coatings on quality of fresh-cut mangoes (Mangifera indica L.). Proceedings of the Florida State Horticultural Society,117: 382-388.

Prusky, D., Kobiler, I., Zaubermann, G., Fuchs, Y. (1993). Preharvest conditions and postharvest treat-ments affecting the incidence of decay in mango fruits during storage. Acta Hortic., 341: 307-320, DOI: 10.17660/ActaHortic.1993.341. 34

Ranganna, S. (1979). Manual of annalysis of fruits and vegetables products. Tata McGrwaw Hill Publishig Co. Ltd., New Dehli, India, p. 312.

Sajib, M.A.M., Jahan, S., Islam, M.Z., Khan, T.A., Saha, B.K. (2014). Nutritional evaluation and heavy metals content of selected tropical fruits in Bangladesh. Int.Food Res.J., 21(2): 609-615.

Santini, A., Romano, R., Meca, G., Raiola, A. & Ritieni, A. (2014). Antioxidant activity and quality of apple juices and puree after in vitro digestion. J. Food Res., 3(4): 41-50, DOI:10.5539/jfr.v3n4p41

Shafique, M.Z., Ibrahim, M., Helali, M.O.H., Biswas, S.K. (2006). Studies on the physiological and biochemical composition of different mango cultivars at various maturity levels. Bangladesh J.Sci.Ind. Res., 41(1-2): 101-108, DOI: 10.3329/bjsir. v41i1.279

Ueda, M., Sasaki, K., Utsunomiya, N., Inaba, K., Shimabayashi, Y. (2000). Changes in physical and chemical properties during maturation of mango fruit (Mangifera indica L.) cultured in a plastic greenhouse. Food Sci.Technol.Res., 6(4): 299-305.

El Sabagh A., Hasan M.K., Hossain M.U., Islam M.S., Kamal M.M., Khatun H., Mozid M.A., Plabon M.E.A., Rashid M.M., Rayhan M.F.