Paul Corneliu Boișteanu, Diana Remina Manoliu, Florin Daniel Lipşa, Mihai Cătălin Ciobotaru, Gabriela Frunză, Marius Mihai Ciobanu

ABSTRACT. This study aimed to evaluate and sensorily describe membrane-emulsified poultry and pork meat products (frankfurter sausages) manufactured in the USV Iași Meat Processing Workshop, products to which celery powder was added. Six technology sheets were developed to obtain six batches of products (three chicken and three pork): C1 (66% chicken breast, 17% pork backfat, 1.8% celery powder) and P1 (66% pork, 17% pork backfat, 1.8% celery powder), C2 (56% chicken breast, 24% pork backfat, 3.5% celery powder) and P2 (56% pork, 24% pork backfat, 3.5% celery powder) and C3 (48% chicken breast, 31% pork backfat, 4.5% celery powder) and P3 (48% pork, 31% pork backfat, 4.5% celery powder). The samples were evaluated in terms of instrumental colour and sensory evaluation (acceptability test and CATA – check-all-that-apply). The results showed significant differences (p < 0.05) between the samples regarding the instrumental colour, chicken meat frankfurter sausages having significantly higher lightness values (L*) compared to pork frankfurter sausages, and in terms of the proportion of raw materials: the lightness increased significantly in direct proportion to the percentage of fat added. According to the CATA analysis, the evaluators associated a pink colour and meaty flavour with batch 1 products and attributes such as uniformity of colour, characteristic flavour, the right amount of seasoning and smooth texture were identified in all six batches of products. However, the batches with the highest scores on the hedonic scale, considered acceptable by the evaluators, were C1, P1 and C2.

Keywords: sensory evaluation; frankfurter sausages; colour; celery powder.

Cite

ALSE and ACS Style

Boișteanu, P.B.; Manoliu, D.R.; Lipșa, F.D.; Ciobotaru, M.C.; Frunză, G.; Ciobanu, M.M. Sensory characterisation of emulsified sausages incorporating celery powder and obtained with different techno-logical parameters. Journal of Applied Life Sciences and Environment 2022, 55(1), 100-109.

https://doi.org/10.46909/alse-551050

AMA Style

Boișteanu PB, Manoliu DR, Lipșa FD, Ciobotaru MC, Frunză G, Ciobanu MM. Sensory characterisation of emulsified sausages incorporating celery powder and obtained with different techno-logical parameters. Journal of Applied Life Sciences and Environment. 2022; 55(1): 100-109.

https://doi.org/10.46909/alse-551050

Chicago/Turabian Style

Boișteanu, Paul Corneliu, Diana Remina Manoliu, Florin Daniel Lipşa, Mihai Cătălin Ciobotaru, Gabriela Frunză, and Marius Mihai Ciobanu. 2022. “Sensory characterisation of emulsified sausages incorporating celery powder and obtained with different techno-logical parameters” Journal of Applied Life Sciences and Environment 55, no. 1: 100-109.

https://doi.org/10.46909/alse-551050

View full article (HTML)

Sensory Characterisation of Emulsified Sausages Incorporating Celery Powder and Obtained With Different Technological Parameters

Paul Corneliu BOIȘTEANU, Diana Remina MANOLIU, Florin Daniel LIPŞA, Mihai Cătălin CIOBOTARU, Gabriela FRUNZĂ and Marius Mihai CIOBANU*

“Ion Ionescu de la Brad” University of Life Sciences, Iaşi; e-mail: paulb@uaiasi.ro; manoliudiana96@yahoo.com; flipsa@uaiasi.ro; cmciobotaru@uaiasi.ro; frunza.gabriela@uaiasi.ro

*Correspondence: mar.ciobanu@yahoo.com

Received: Nov. 17, 2022. Revised: Nov. 29, 2022. Accepted: Dec. 08, 2022. Published online: Jan. 06, 2023

ABSTRACT. This study aimed to evaluate and sensorily describe membrane-emulsified poultry and pork meat products (frankfurter sausages) manufactured in the USV Iași Meat Processing Workshop, products to which celery powder was added. Six technology sheets were developed to obtain six batches of products (three chicken and three pork): C1 (66% chicken breast, 17% pork backfat, 1.8% celery powder) and P1 (66% pork, 17% pork backfat, 1.8% celery powder), C2 (56% chicken breast, 24% pork backfat, 3.5% celery powder) and P2 (56% pork, 24% pork backfat, 3.5% celery powder) and C3 (48% chicken breast, 31% pork backfat, 4.5% celery powder) and P3 (48% pork, 31% pork backfat, 4.5% celery powder). The samples were evaluated in terms of instrumental colour and sensory evaluation (acceptability test and CATA – check-all-that-apply). The results showed significant differences (p < 0.05) between the samples regarding the instrumental colour, chicken meat frankfurter sausages having significantly higher lightness values (L*) compared to pork frankfurter sausages, and in terms of the proportion of raw materials: the lightness increased significantly in direct proportion to the percentage of fat added. According to the CATA analysis, the evaluators associated a pink colour and meaty flavour with batch 1 products and attributes such as uniformity of colour, characteristic flavour, the right amount of seasoning and smooth texture were identified in all six batches of products. However, the batches with the highest scores on the hedonic scale, considered acceptable by the evaluators, were C1, P1 and C2.

Keywords: sensory evaluation; frankfurter sausages; colour; celery powder.

INTRODUCTION

The world’s human population is projected to grow to 9.7 billion by 2050 and 10.3 billion by 2100 (UN, 2022), doubling the current demand for meat products. Moreover, the increase in demand for animal products will also be driven by rising population incomes, with production expected to double to 455 million tonnes (Mt) by 2050 (Alfaia et al., 2022). Global meat supply will expand to meet growing demand over the 2022–2031 period, as projected by FAO, reaching 377 Mt by 2031, but growing more slowly than in the last decade. World consumption of pork and poultry meat is projected to increase to 129 Mt and 154 Mt, respectively, over the next 10 years (FAO, 2022).

Fat is an important component of the human diet and contributes to the flavour, tenderness, juiciness, appearance and texture of meat products, all of which are intrinsic quality characteristics along with overall acceptability. Nutritional properties depend on animal genetics, nutrition and husbandry practices, and post-mortem processes that occur during the muscle-to-meat process (Islam et al., 2019).

However, emulsified meat products have high levels of saturated fatty acids (SFA) and cholesterol due to the raw materials (Pires et al., 2019).

Emulsified meat products contain meat, fat, salt, ice and spices. Recently, the meat industry has been looking for additives to make meat products more nutritionally beneficial (e.g. by reducing their calorie content, adding fibre, minerals or bioactive compounds, or reducing their sodium content) (Schuh et al., 2013; Pires et al., 2021).

One of the major problems in manufacturing and trading these meat products is the rapid deterioration of their quality. One of the primary causes of chemical degradation in food is lipid oxidation. The oxidation of food results in a rotten flavour and a decline in the sensory and nutritional quality of the items, rendering them unsuitable for consumption. These products include effective antioxidants to prevent or minimise oxidative damage.

Application of antioxidants is the simplest method for minimising lipid oxidation (Sharma et al., 2018). To prevent spoilage, both natural and synthetic antioxidants are widely used to inhibit fat oxidation and prolong shelf life (Hossain et al., 2021). Nevertheless, consumers are concerned about the addition of synthetic substances to food due to the possible toxicity of these elements. Over time, this has boosted the need for natural food additives, prompting researchers to investigate options to chemical food additives. Due to their biological capabilities and taste characteristics, several natural alternatives have been widely utilised in culinary preparations (Sharma et al., 2019).

A common natural preservative ingredient is celery (Apium graveolens L.) (Oliveira et al., 2021). Celery, as a plant of the family Apiaceae, is a tasty vegetable, highly valued for its nutritional and therapeutic values. Celery also contains betalains, which have free radical scavenging and antioxidant activity (Alkazzaz et al., 2022). It is recognised for its antioxidant property which is related to the presence of compounds such as caffeic acid, p-coumaric acid, ferulic acid, apigenin, luteolin, kaempferol, tannins and saponins, which indicates its health-promoting potential (Kooti and Daraei, 2017).

Manufacturers use celery because it has a low plant pigment content and a mild flavour, which does not greatly alter the taste characteristics of the product to which it is added (Horsch et al., 2014).

In this context, the present study aimed to manufacture six varieties of products (three varieties of chicken frankfurter sausage and three varieties of pork frankfurter sausage), with the novelty of adding celery powder to the composition. Prior to their usage as “natural preservatives”, however, thorough assessment is required to ensure that additional food products are sensorily acceptable to consumers. The experimental batches of products were manufactured with different proportions of added ingredients. The products obtained were characterised in terms of sensory and colour parameters (L*, a*, b*) to establish their acceptability for consumption and to determine colour differences between the experimental batches.

MATERIALS AND METHODS

The experimental batches were made in the Meat Processing Workshop of the University of Life Sciences “Ion Ionescu de la Brad” Iași. The list of ingredients used and their proportions are shown in Table 1.

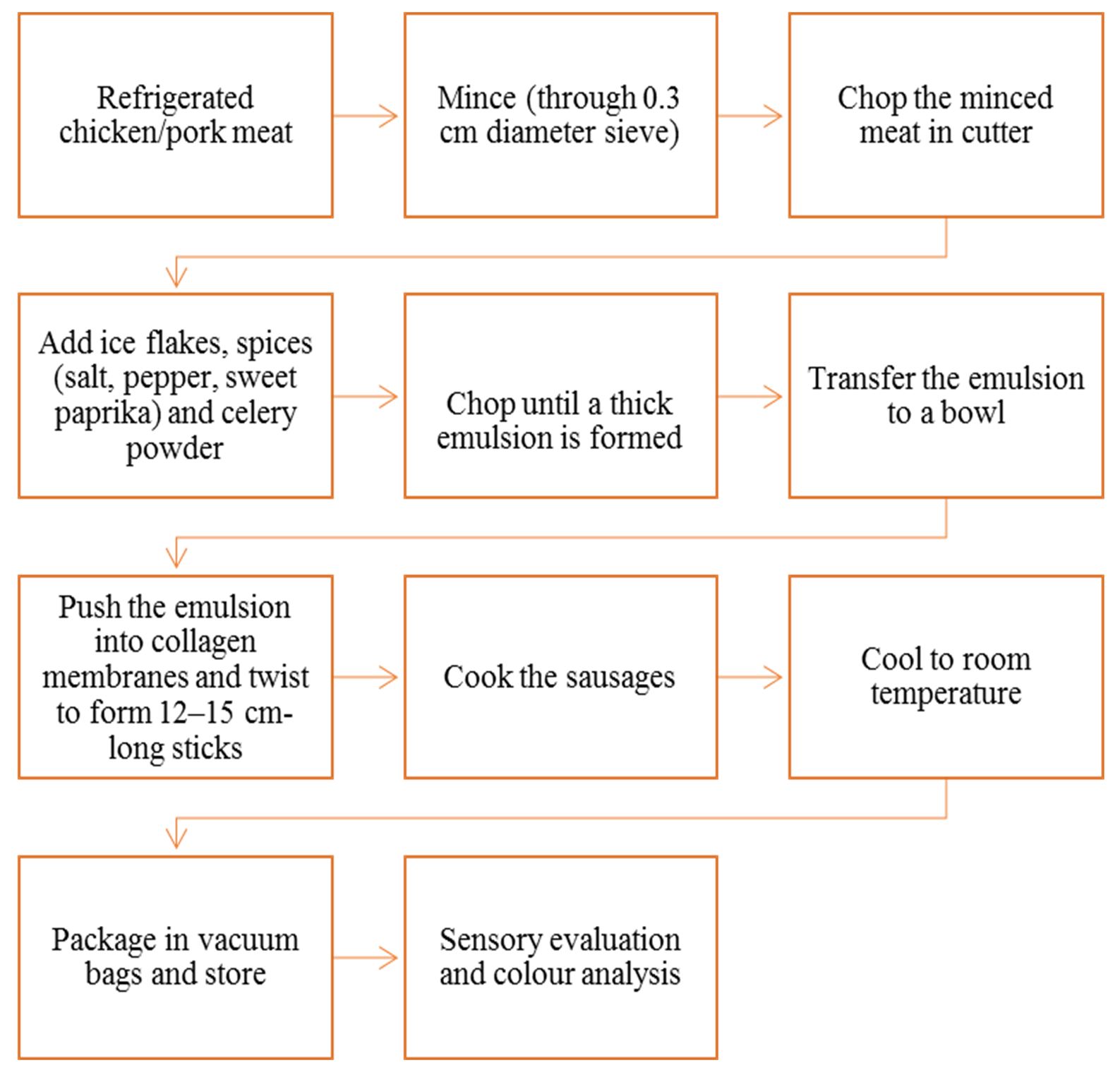

The manufacturing process involved specific steps for emulsified meat products, as shown in Figure 1. The meat emulsion was prepared using a GRINDER WP – 105 grinding machine and a TITANE V 45L cutter.

The heat treatment involved four stages (drying, smoking, boiling and air drying) carried out at different parameters, taking into account the percentages of raw materials introduced, as shown in Table 2. Regarding the heat treatment performed on the emulsified products, the relative humidity, heating rate and ultimate temperature are considered of special interest due to their effects on the yield, texture, colour and microbiological properties of the products. The link between these factors and the chemical and physical changes happening in proteins and lipids may have varying impacts on the properties of meat products, depending on their composition and size. High temperatures reduce oxidation activation energy and, in particular, convert hydroperoxides into free radicals, which promote lipid peroxidation and the formation of off-flavours (Kanner, 1994; Colmenero, 1996).

Therefore, the temperatures for the heating treatment were correlated with the amount of fat that was present in each batch. In order to ensure the product’s microbiological safety, the minimum temperature in the product’s centre had to reach 69 °C in the boiling stage of the heat treatment.

The colour determination of the samples was carried out according to the methods described by Hossain et al. (2021), with a Konica Minolta Chroma Meter CR-410 portable chromameter. The colour of the samples was read using illuminator C at an observation angle of 2°. The mean values of 10 readings were recorded. Each batch was evaluated using one package of product, with each package including six separate samples.

Table 1

Proportions of the ingredients in the experimental batches of sausages

|

|

C1/P1 (%) |

C2/P2 (%) |

C3/P3 (%) |

|

Chicken breast/pork |

66 |

56 |

48 |

|

Pork backfat |

17 |

24 |

31 |

|

Celery powder |

1.8 |

3.5 |

4.5 |

|

Salt |

2.0 |

2.0 |

2.0 |

|

Pepper |

0.5 |

0.5 |

0.5 |

|

Sweet paprika |

0.5 |

0.5 |

0.5 |

|

Ice flakes |

12.2 |

13.5 |

13.5 |

|

Total |

100 |

100 |

100 |

C1, C2, C3 – experimental batches of poultry; P1, P2, P3 – experimental batches of pork.

Table 2

Heat treatment scheme

|

Experimental batch 1 |

Experimental batch 2 |

Experimental batch 3 |

|

|

|

|

|

t = 30 min; U = 20%; T = 70 °C (60 °C inside the product) |

t = 30 min; U = 20%; T = 60 – 62 °C (56–58 °C inside the product) |

t = 20 min; U = 20%; T = 60 °C (56 °C inside the product) |

|

|

Smoking |

|

|

t = 15 min; U = 20%; T = 70 °C (60 °C inside the product) |

t = 15 min; U = 20%; T = 60 – 62 °C (56–58 °C inside the product) |

t = 10 min; U = 20%; T = 60 °C (56 °C inside the product) |

|

|

Boiling |

|

|

U = 99%; T = 72 °C (69 °C inside the product) |

U = 99%; T = 72 °C (69 °C inside the product) |

U = 99%; T = 72 °C (69 °C inside the product) |

|

|

Air Drying |

|

|

t = 10 min; U = 20%; T = 72 °C (69 °C inside the product) |

t = 5 min; U = 20%; T = 72 °C (69 °C inside the product) |

t = 5 min; U = 20%; T = 72 °C (69 °C inside the product) |

t – time; U – humidity; T – temperature.

The sensory evaluation of the final products was performed in the Sensory Analysis Laboratory of USV Iași. In accordance with Jorge et al. (2016) and Massingue et al. (2018), CATA (check-all-that-apply) questions were utilised to define the sensory features of each product. To compose the CATA test, 22 descriptive terms were chosen (colour: uniform, pink, brightness, opacity; aroma: acid, characteristic, intense meaty, celery, strong celery, rancid; taste: salty, unsalty, tasteless, spicy (right amount of seasoning), bitter, sour, greasy mouthfeel; texture: smooth, brittle, hard, dry, oily/fatty).

A panel consisting of 45 untrained members performed an acceptability test using a 9-point hedonic scale with 1 point meaning disliked extremely and 9 meaning liked extremely (Meilgaard et al., 2016; Pires et al., 2019). The acceptability test tracked general attributes of appearance, texture, aroma, taste, quality and overall acceptability. All participants confirmed that they are consumers of frankfurter sausages.

The results obtained for the colour parameters and the acceptability test were subjected to the ANOVA statistical test, comparing the mean values by using Tukey’s test at a significance level of 5% (p < 0.05). The CATA test results were expressed as the frequency of citation for each sensory term of each sample, using XLStat software (Excel Addinsoft, version 2022).

RESULTS AND DISCUSSION

Colour parameters (L*, a*, b*) showed significant differences (p < 0.05) caused by the changes in composition of the six products (Table 3). A pronounced increase in lightness (L*) was observed in the two batches with a decreased percentage of raw meat added to the product. This finding is consistent with the results obtained by Guerra et al. (2011), who stated that when fat content is reduced, sausages become darker (lower L* values). Values for redness (a*) showed a steady decrease, samples with a higher percentage of meat having a more pronounced red colour. The b* values showed obvious differences between the poultry samples, while those of the pork samples were in a narrower range, 24.74 ± 0.378 (P1) to 25.49 ± 0.529 (P3).

Table 4 shows the mean scores (± standard deviation) received from the subjects for every sensory attribute evaluated. By comparing those mean scores it can be seen that the differences between the six samples were significant (p < 0.05) for all the attributes evaluated. However, C3 and P3 registered lower mean scores for sensory acceptance compared to samples 1 and 2 of the two batches. Also, the results show that increasing the percentages of fat and celery powder in the products lowered their acceptance by possible consumers. Even with the differences observed in the samples evaluated, all processed products showed scores in the range of 5 (neither like nor dislike) to 7 (like in moderation). According to the literature (Meilgaard et al., 2016), the limit for acceptance when using a 9-point hedonic scale is 6.3, products with means above this limit being considered accepted for consumption. In this case study, the products that received scores above 6.3 for all the sensory attributes were C1, C2 and P1; for C3, P2 and P3, the scores for texture, aroma, taste and general quality attributes were below 6.3, indicating that not all treatments would be acceptable to consumers.

Table 3

Mean (± standard deviation) of colour parameters (L*, a*, b*) for the samples of frankfurter-type sausages

|

|

Poultry samples |

Pork samples |

|

||||

|

C1 |

C2 |

C3 |

P1 |

P2 |

P3 |

p value |

|

|

L* |

63.31 ± 0.496d |

68.66 ± 0.490b |

70.24 ± 0.755ab |

54.69 ± 0.612e |

66.86 ± 0.338c |

71.86 ± 0.552a |

< 0.0001 |

|

a* |

9.17 ± 0.305a |

7.28 ± 0.188b |

5.32 ± 0.173c |

9.64 ± 0.446a |

6.85 ± 0.160b |

4.626 ± 0.195d |

0.035 |

|

b* |

31.38 ± 0.422a |

29.97 ± 0.246b |

25.91 ± 0.189c |

24.74 ± 0.378d |

25.29 ± 0.411cd |

25.49 ± 0.529c |

< 0.0001 |

L* = Lightness; a* = redness; b* = yellowness. Different letters next to the means in the same row indicate significant differences between samples by Tukey’s test (p < 0.05).

Table 4

Mean (± standard deviation) sensory acceptance scores of frankfurters

|

|

Poultry samples |

Pork samples |

||||

|

C1 |

C2 |

C3 |

P1 |

P2 |

P3 |

|

|

Appearance |

7.15 ± 1.22a |

7.02 ± 1.25b |

6.69 ± 1.16c |

6.87 ± 1.64bc |

6.55 ± 1.57d |

6.44 ± 0.84d |

|

Texture |

7.31 ± 1.18a |

6.91 ± 1.22b |

6.04 ± 1.58c |

6.82 ± 1.48b |

6.07 ± 1.19c |

5.78 ± 0.99d |

|

Aroma |

6.93 ± 1.03a |

6.75 ± 1.22ab |

5.98 ± 1.52cd |

6.73 ± 1.09ab |

6.11 ± 1.46c |

5.91 ± 1.18cd |

|

Taste |

7.07 ± 1.14a |

6.80 ± 1.41b |

6.00 ± 1.62c |

6.82 ± 1.37b |

6.29 ± 1.47d |

6.04 ± 1.15c |

|

Acceptability |

7.09 ± 1.12a |

6.95 ± 1.29a |

6.24 ± 1.64b |

7.04 ± 1.41a |

6.13 ± 1.03bc |

5.84 ± 1.04c |

The same letter next to the mean scores presented with the same row indicates no significant difference between samples (p < 0.05) in the Tukey test.

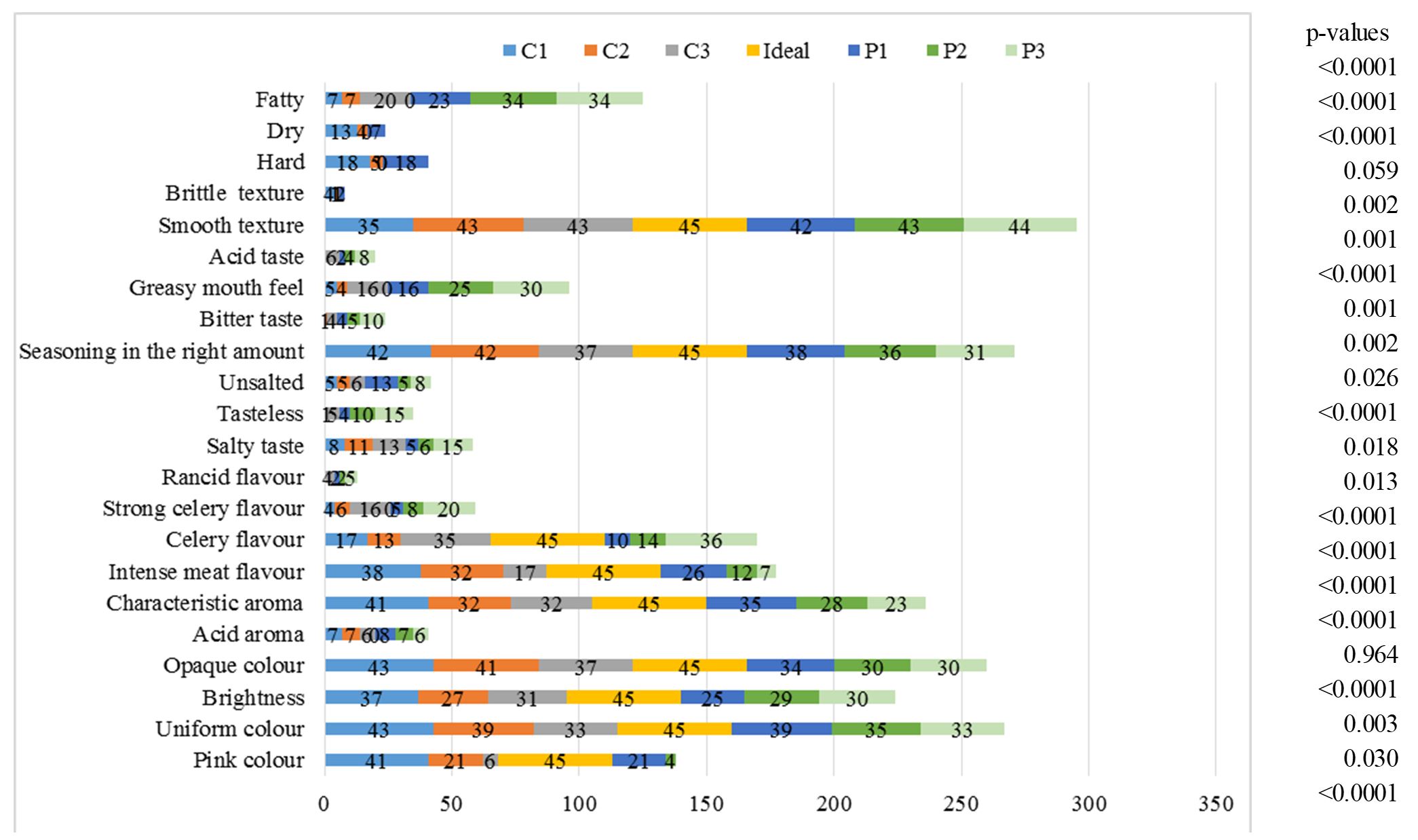

The results of the CATA sensory assessment are shown in Figure 2, which represents the frequency of responses from the evaluators for each descriptive term and each sample. CATA statistical analysis displays significant differences between samples C3 and P3 and the rest, due to the sensory attribute: pink colour, brightness, intense meaty aroma and celery flavour. For the attributes of oily/fatty texture and greasy mouthfeel, samples C1 and C2 differed from the others, receiving a lower number of responses.

For the ideal product, a panel of 12 participants, aged 20–27 (a group recruited from members of a scientific circle organised within the sensory analysis discipline), were asked to describe the sensory features of the products and to indicate their ideal sensory attributes. On the CATA questionnaire, sensory attributes deemed ideal received a value of 1, whereas undesirable or negative sensory attributes received a score of 0.

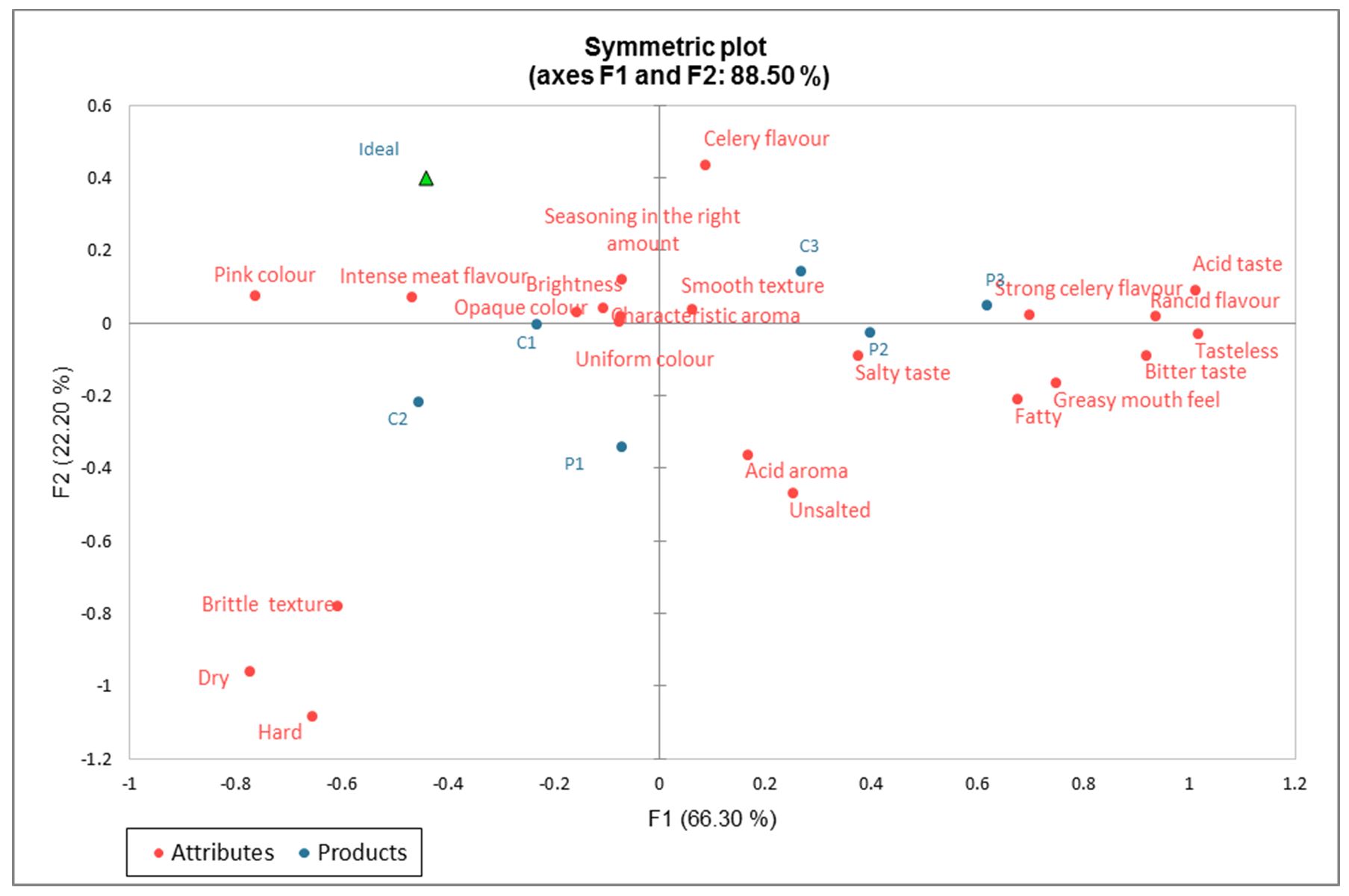

CATA results were also assessed by multiple factor analysis (MFA; Figure 3). Factors 1 and 2 explained the variation between samples. The similarity plot shows which attributes should (or should not) be displayed by the ideal product and which samples were closest to it. Hence, the ideal product should have a pink, uniform colour, characteristic, intense meaty flavour, ideally spicy. It can be seen that sample C1 is the closest to the ideal, and therefore has the sensory characteristics most desired by consumers. Samples C2 and P1 are also located in the left quadrant, being closer to the desired sensory attributes, while samples C3, P2 and P3 are the furthest from the ideal, being described as having a more pronounced celery flavour, a more salty and acidic taste, a fatty texture and greasy mouthfeel.

Figure 2 – Number of citations of each sensory attribute in the CATA test for the six frankfurter samples. Values of p < 0.05 indicate attribute which showed significant differences between treatments according to the Cochran test

CONCLUSION

Increasing the percentage of fat and the amount of celery powder, as well as changing the meaty raw material, resulted in significant differences between the sausage samples in terms of colour parameters and sensory acceptability characteristics. Sensory acceptability decreased with an increasing fat percentage and was also higher for poultry products. Thus, C1 and P1 samples, but also C2, were well accepted by the evaluators, with an average score of around 7.0. The results show that a maximum of 3.5% celery powder can be used in the production of these products because for samples 1 and 2 of the two batches no negative celery flavour was evident. However, as the amount of celery powder increased, the number of evaluators perceiving an intense celery flavour increased.

Author Contributions: conceptualization, P.C.B., M.M.C.; methodology, M.M.C., G.F.; analysis, D.R.M., M.C.C.; investigation, D.R.M., M.C.C.; resources, P.C.B., M.M.C., F.D.L.; data curation, P.C.B., M.M.C.; writing, D.R.M., M.C.C.; review, P.C.B., M.M.C., F.D.L.; supervision, P.C.B.

All authors declare that they have read and approved the publication of the manuscript in this present form.

Funding: There was no external funding for this study.

REFERENCES

Alfaia, C.M.; Costa, M.M.; Lopes, P.A.; Pestana, J.M.; Prates, J.A.M. Use of Grape By-Products to Enhance Meat Quality and Nutritional Value in Monogastrics. Foods. 2022, 11, 2754. https://doi.org/10.3390/foods11182754.

Alkazzaz, S.R.M.A.; Abdelrahman, H.A.; Ahmed, A.M.; Dora, E.-D.H.I.; Helal, I.M.; Ahmed, N.I.H. Effect of Replacing Sodium Nitrite with Celery on Sensory and Chemical Quality of Popular Dry Sausage. Journal of Advanced Veterinary Research. 2022, 12, 404-408. https://advetresearch.com/index. php/AVR/article/view/1026 .

Colmenero, F.J. Technologies for developing low-fat meat products. Trends in Food Science & Technology. 1996, 7, 41-48. https://doi.org/10.10 16/0924-2244(96)81327-6 .

Guerra, I.C.D.; Félex, S.S.S.; Meireles, B.R.L.M.; Dalmás, P.S.; Moreira, R.T.; Honório, V.G.; Morgano, M.A.; Milani, R.F.; Benevides, S.D.; Queiroga, R.C.R.E.; Madruga, M.S. Evaluation of goat mortadella prepared with different levels of fat and goat meat from discarded animals. Small Ruminant Research. 2011, 98, 59-63. https://doi. org/10.1016/j.smallrumres.2011.03.019

Horsch, A.M.; Sebranek, J.G.; Dickson, J.S.; Neibuhr, S.E.; Larson, E.M.; Lavieri, N.A.; Ruther, B.L.; Wilson, L.A. The effect of pH and nitrite concentration of the antimicrobial impact of celery juice concentrate compared with conventional sodium nitrite on Listeria monocytogenes. Meat Science. 2014, 96, 400-407. https://doi. org/10.1016/j.meatsci.2013.07.036.

Hossain, M.S.; Rokib, M., Habib, M., Kabir, M.H., Hashem, M.A., Azad, M.A.K., Rahman, M.M., Ali, M.S. Quality of spent hen sausages incorporated with fresh ginger extract. Journal of Bangladesh Agricultural University 2021, 1 (01):1-6.

Islam, A., Sadakuzzaman, M.; Hossain, M.A.; Hossain, M.M.; Hashem, M.A. Effect of gamma irradiation on shelf life and quality of indigenous chicken meat. Journal of Bangladesh Agricultural University. 2019, 17, 560-566. https://www.banglajol.info/index.php/JBAU/article/view/44626.

Jorge, E.C.; Mendez, A.C.G.; Auriema, B.E.; Cazedey, H.P.; Fontes, P.R.; Ramos, A.L.S.; Ramos, E.M. Application of a check-all-that-apply question for evaluating and characterizing meat products. Meat Science. 2015, 100, 124-133. https:// doi.org/10.1016/j.meatsci.2014.10.002

Kanner, J. Oxidative processes in meat and meat products: quality implications. Meat science. 1994, 36, 169-189. https://doi.org/10.1016/0309-1740(94)90040-X.

Kooti, W.; Daraei, N. A Review of the Antioxidant Activity of Celery (Apium graveolens L). Journal of Evidence-Based Complementary & Alternative Medicine. 2017, 22, 1029-1034. https://doi.org/10.1177/2156587217717415.

Massingue, A.A.; de Almeida Torres Filho, R.; Fontes, P.R.; de Lemos Souza Ramos, A.; Fontes, E.A.F.; Perez, J.R.O.; Ramos, E.M. Effect of mechanically deboned poultry meat content on technological properties and sensory characteristics of lamb and mutton sausages. Asian-Australasian Journal of Animal Sciences. 2018, 31, 576-584. https://doi.org/10.5713/ajas. 17.0471.

Meilgaard, M.C.; Civille, G.V.; Carr, B.T. Sensory Evaluation Techniques, Fifth Edition. Boca Raton: CRC Press, Florida, USA, 2016, p. 325-330.

OECD – FAO, 2022. Agricultural Outlook 2022-2031; OECD: Paris, France. Available online at: https://doi.org/10.1787/19991142 (accessed on 12 September 2022).

Oliveira, W.A.; Rodrigues, A.R.P.; Oliveira, F.A.; Oliveira, V.S.; Laureano-Melo, R.; Stutz, E.T.G.; Lemos Junior, W.J.F.; Paula, B.P.; Esmerino, E.A.; Corich, V.; Giacomini, A.; Rodrigues, P.; Luchese, R.H.; Guerra, A.F. Potentially probiotic or postbiotic pre-converted nitrite from celery produced by an axenic culture system with probiotic lacticaseibacilli strain. Meat Science. 2021, 174, 108408. https://doi. org/10.1016/j.meatsci.2020.108408.

Pires, M.A.; Rodrigues dos Santos, I.; Carvalho Barros, J.; Trindade, M.A. Kelly’s repertory grid method applied to develop sensory terms for consumer characterization (check-all-that-apply) of omega‑3 enriched bologna sausages with reduced sodium content. European Food Research and Technology. 2021, 247, 285-293. https://doi.org/10.1007/s00217-020-03 598-6.

Pires, M.A.; Rodrigues dos Santos, I.; Carvalho Barros, J.; Trindade, M.A. Effect of replacing pork backfat with Echium oil on technological and sensory characteristics of bologna sausages with reduced sodium content. LWT – Food Science and Technology. 2019, 109, 47-54. https://doi.org/10. 1016/j.lwt.2019.04.009.

Schuh, V.; Allard, K.; Herrmann, K.; Gibis, M.; Kohlus, R.; Weiss, J. Impact of carboxymethyl cellulose (CMC) and microcrystalline cellulose (MCC) on functional characteristics of emulsified sausages. Meat Science. 2013, 93, 240-247. https://doi.org/10.1016/j.meat sci.2012.08.025.

Sharma, H.; Mendiratta, S.K.; Agarwal, R.; Goswami, M. Optimization of Various Essential Oils and Their Effect on the Microbial and Sensory Attributes of Chicken Sausages. Agricultural Research. 2019, 8, 374-382. https://doi. org/10.1007/s40003-018-0367-x.

Sharma, H.; Mendiratta, S.K.; Agrawal, R.K.; Talukder, S.; Kumar, S. Studies on the potential application of various blends of essential oils as antioxidant and antimicrobial preservatives in emulsion based chicken sausages. British Food Journal. 2018, 120, 1398-1411. https://doi.org/10.1108/BFJ-03-2018-0185.

United Nations, 2022 – Department of Economic and Social Affairs, Population Division. Available online at: http://creativecommons.org/licenses/by/3.0/igo (accessed on 5 September 2022).

Academic Editor: Prof. Dr. Daniel Simeanu

Publisher Note: Regarding jurisdictional assertions in published maps and institutional affiliations ALSE maintain neutrality.

Boișteanu Paul Corneliu, Ciobanu Marius Mihai, Ciobotaru Mihai Cătălin, Frunză Gabriela, Lipșa Florin Daniel, Manoliu Diana Remina