Roxana Nicoleta Rațu, Marius Giorgi Usturoi, Răzvan Mihail Radu-Rusu, Ionuț Dumitru Veleșcu, Florin Daniel Lipșa, Vlad Nicolae Arsenoaia, Alina Narcisa Postolache, Ioana Cristina Crivei, Petru Marian Cârlescu

ABSTRACT. Large amounts of chemicals with useful properties can be found in by-products of the processing of grapes. Consumer interest in functional foods has increased recently, with dairy products dominating this market. Constituents from grape-based by-products that are naturally occurring in grapes have the potential to enhance the functional qualities of dairy products and lessen environmental damage. As a result, the goal of this research is to provide crucial information on the use of grape skin powder as a helpful ingredient in the manufacture of cheese. In this study, grape skin powder (GSP) was added to cheese to increase its bioactive compounds content and antioxidant activity. Total phenolic content (TPC) was significantly greater in the enriched cheese (5.483±0.443 mg C3G/100 g DW). Adding 2% grape skin powder to the cheese formulation gave an increase of 0.295 mg CE/g DW of TFC and 2.046 mg GAE/g DW of TPC. The GSP-supplemented cheese also showed greater antioxidant activity than the control. This study demonstrates that grape by-products can effectively transfer beneficial compounds to cheese.

Keywords: food; functional; grapes by-products; quality.

Cite

ALSE and ACS Style

Rațu, R.N.; Usturoi, M.G.; Radu-Rusu, R.M.; Veleșcu, I.D.; Lipșa, F.D.; Arsenoaia, V.N.; Postolache, A.N.; Crivei, I.C.; Cârlescu, P.M. Effect of grape skin powder addition on chemical, nutritional and technological properties of cheese. Journal of Applied Life Sciences and Environment 2023, 56 (1), 41-58.

https://doi.org/10.46909/alse-561084

AMA Style

Rațu RN, Usturoi MG, Radu-Rusu RM, Veleșcu ID, Lipșa FD, Arsenoaia VN, Postolache AN, Crivei IC, Cârlescu PM. Effect of grape skin powder addition on chemical, nutritional and technological properties of cheese. Journal of Applied Life Sciences and Environment. 2023; 56 (1): 41-58.

https://doi.org/10.46909/alse-561084

Chicago/Turabian Style

Rațu, Roxana Nicoleta, Marius Giorgi Usturoi, Răzvan Mihail Radu-Rusu, Ionuț Dumitru Veleșcu, Florin Daniel Lipșa, Vlad Nicolae Arsenoaia, Alina Narcisa Postolache, Ioana Cristina Crivei, and Petru Marian Cârlescu. 2023. “Effect of grape skin powder addition on chemical, nutritional and technological properties of cheese” Journal of Applied Life Sciences and Environment 56, no. 1: 41-58.

https://doi.org/10.46909/alse-561084

View full article (HTML)

Effect of Grape Skin Powder Addition on Chemical, Nutritional and Technological Properties of Cheese

Roxana Nicoleta RAȚU1, Marius Giorgi USTUROI2, Răzvan Mihail RADU-RUSU2, Ionuț Dumitru VELEȘCU1, Florin Daniel LIPȘA1, Vlad Nicolae ARSENOAIA3, Alina Narcisa POSTOLACHE4, Ioana Cristina CRIVEI5 and Petru Marian CÂRLESCU1*

1Institute of Chemistry of Moldova State University, Chisinau, Republic of Moldova; e-mail: ionbulhac@yahoo.com; verzub@mail.ru

2Institute of Genetics, Physiology and Plant Protection of Moldova State University, Chisinau, Republic of Moldova; e-mail: anastasia.stefirta@gmail.com

3Institute for Research, Innovation and Technology Transfer of “Ion Creangă” State Pedagogical University, Chișinău, Republic of Moldova; e-mail: liliabrinza@mail.ru

*Correspondence: maria.cocu@sti.usm.md; mariacocu@gmail.com

Received: Oct. 04, 2023. Revised: Dec. 07, 2023. Accepted: Dec. 14, 2023. Published online: Feb. 09, 2024

ABSTRACT. Large amounts of chemicals with useful properties can be found in by-products of the processing of grapes. Consumer interest in functional foods has increased recently, with dairy products dominating this market. Constituents from grape-based by-products that are naturally occurring in grapes have the potential to enhance the functional qualities of dairy products and lessen environmental damage. As a result, the goal of this research is to provide crucial information on the use of grape skin powder as a helpful ingredient in the manufacture of cheese. In this study, grape skin powder (GSP) was added to cheese to increase its bioactive compounds content and antioxidant activity. Total phenolic content (TPC) was significantly greater in the enriched cheese (5.483±0.443 mg C3G/100 g DW). Adding 2% grape skin powder to the cheese formulation gave an increase of 0.295 mg CE/g DW of TFC and 2.046 mg GAE/g DW of TPC. The GSP-supplemented cheese also showed greater antioxidant activity than the control. This study demonstrates that grape by-products can effectively transfer beneficial compounds to cheese.

Keywords: food; functional; grapes by-products; quality.

INTRODUCTION

The production of waste, which can be a source of many food by-products, is one of the main issues the food industry faces (Caldeira et al., 2019). It represents a wasteful use of natural resources and is regarded as a major global challenge from all perspectives. Given the high nutritional value and instability of these by-products when subjected to industrial and environmental processes, these chemicals are complex (Bedoic et al., 2019). Finding collaborative solutions to waste management and resource depletion is urgently needed. We need to encourage policies based on environmentally friendly and sustainable technologies to re-use waste appropriately as raw resources. We can lessen the environmental impact of these valuable resources by utilizing them to their full potential (Díaz-Vela et al., 2015).

Grapes are among the most widely produced crops in the world. In Europe, a remarkable 3.5 million hectares of land are set aside to grow this delicious fruit. An astounding 27 million tons of grapes are produced annually as a result of this enormous effort, demonstrating the scope and significance of grape farming in this area (FAO, 2019).

According to recent estimates, there are an astounding 14.5 million tons of grape by-products produced each year. The bulk of this enormous amount of waste is made up of grape pomace, which accounts for between 50 and 65 percent of the volume of all by-products. The fact that grape skin makes up the majority of this pomace emphasizes how important it is as a source of beneficial nutrients and bioactive chemicals (Coelho et al., 2023).

As sources of nutrients and different bioactive chemicals for nutrition and food, food industry by-products are highly significant from an environmental standpoint (Câmara et al., 2020).

The nutritional value of these by-products depends on several elements, such as the original nutrient makeup and the processing method used. In particular, grape pomace is understood to have high levels of crude protein, crude fat, crude fibre, ADF, and NDF (Sousa et al., 2014). Additionally, grape pomace has high levels of Ca, P, Mg, K, and Fe in terms of its mineral composition (Karnopp et al., 2017). Maximizing the use of these by-products is therefore essential, both for their nutritional value and for the favourable effects on the environment (Hassan et al., 2020).

The production of functional food products by the addition of grape by-products to various food items would surely result in the introduction of natural functional food elements like dietary fibre and polyphenols in frequently consumed foods (Dwyer et al., 2014). Such actions have a favourable effect on the environment as well as our health. The competitiveness of the food sector can be improved by revamping classic foods and developing modern products that are very well received by consumers. Additionally, this will direct younger customers toward making healthier and more sustainable food choices, so encouraging a healthier lifestyle (Yadav et al., 2018).

The use of grape by-products in various industries, including the beverage, baking, and dairy industries, has significantly advanced food production. With the help of this cutting-edge strategy, producers have fully utilized grapes-not just for their fruit or juice, but also for their by-products. As a result, grape by-products are now a crucial component in the food industry, adding a new flavour profile and nutritious advantages to various products (Ayar et al., 2017; Dwyer et al., 2014).

In conclusion, research has shown that grape and wine by-products are highly valuable as a rich source of beneficial chemicals that can be used in the manufacture of a variety of dairy products. These dairy products include ice cream, cheese, yogurt, and fermented milks (dos Santos et al., 2017). It is important to highlight that a variety of advantageous nutrients have been discovered to be present in these by-products, which can improve the nutritional content of the finished products. Therefore, adding these by-products to dairy formulas can be a sensible and healthful decision that can also help a food business to remain viable (Kaderides et al., 2020).

Additionally, it has been proposed that adding grape by-products to dairy products would be a practical way to lengthen their shelf life, as shown by earlier research (Tseng et al., 2013). This is because dairy products normally do not contain large levels of phenolic chemicals and antioxidants, while grape by-products do (Kandylis et al., 2021).

It is interesting to note that grape by-products can dramatically boost the total phenolic content and radical scavenging activity of cheese, which is a popular dairy product (Gaglio et al., 2021). Studies have also looked at how grape by-products affect the microbiological elements of dairy production, and in many cases, they found favourable outcomes (Difonzo et al., 2023). It seems that grape by-products have considerable potential as a useful component for improving the quality and longevity of dairy products.

Additionally, the addition of grape by-products can boost protein levels and secondary lipid oxidation while lowering the fat content of cheese. When making tofu, grape by-products can act as a coagulant and alter its textural characteristics and even colour (Zeppa et al., 2021).

In order to provide natural antioxidants and other lipophilic bioactive elements to the cheese composition, the primary goal of the current study was to examine the possible advantages of Merlot grape skin powder. Given that using natural, plant-based ingredients can improve the overall quality and nutritional content of cheeses, the findings of this study could have a significant impact on the cheese industry. Therefore, the purpose of this study is to offer important knowledge about the usage of grape skin powder as a useful component in the production of cheese.

MATERIALS AND METHODS

After being washed, dried, and separated by hand, 30 kg of Merlot grapes sourced from the farm USV-Iasi were processed. The powder was prepared by drying the skin in a laboratory at a temperature of 40°C for 24 hours. The flakes of dried grape skin were ground to a fine powder. When not used, the dried grape skin (GS) powder was maintained in sealed polyethylene bags and kept at -18°C (Pedroza et al., 2011).

The Rediu Iaşi Research Station, part of the University of Life Sciences, contributed 300 litres of cow’s milk from their herd of 55 cattle.

Characterization of grape skin powder

Extraction of bioactive compounds from grape skin powder (GSP). For the ultrasound-assisted extraction, 9 mL of the solvent (80% ethanol), 1 ml of 1% citric acid, and 1 g of dried skins grape powder were used. The extractions were conducted using a sonication water bath (MRC Scientific 193 Instruments, Holon, Israel) at 40°C for 45 minutes. The extraction procedure was carried out three times to obtain extracts full of anthocyanins. The supernatants were then gathered and centrifuged at 6000 rpm and 4°C for 10 minutes. A AVC 2-18, Christ, Shropshire, UK was used to concentrate the resulting supernatants to dryness at 40°C under reduced pressure. The resulting extract was then diluted in the extraction solvent for phytochemical evaluation.

Determination of the Total Anthocyanins Content (TAC) was assessed using a modified pH differential approach (Lee et al., 2005). The samples were diluted (1:10) with the extraction solvent before analysis. Using 200 L of vegetable extract and 800 L of two different buffer solutions (0.025 M potassium chloride buffer at pH 1.0 and 0.4 M sodium acetate buffer at pH 4.5), the absorbance of the diluted extracts was then measured at two different wavelengths, 520 nm and 700 nm (UV-VIS spectrophotometer Libra S22, Biochrom, UK). Results were expressed as milligrams of cyanidin-3-glucoside (mg C3G/g DW) for each gram of dry weight (DW).

Determination of the Total Phenolic Compounds (TPC). Using gallic acid as a reference, the Folin-Ciocalteau technique (Sant’Anna et al., 2012) was used to calculate the extract’s total phenolic compounds content (TPC). In brief, 200 mL of extract was combined with 1 mL of Folin-Ciocalteu reagent and 15.8 mL of distilled water to create a final volume of 17 mL. After 10 minutes, 3 mL of 20% Na2CO3 was added, and the mixture was then maintained at 25°C in a dark environment for 60 minutes. With the aid of data analysis software (Libra S22, Biochrom, UK), the absorbance of the reaction mixture was measured at a wavelength of 765 nm, and the results were reported as mg of gallic acid equivalents (GAE) per gram of dry weight (mg GAE/g DW).

Determination of the Total Flavonoids Compounds (TFC). The total flavonoids compounds were determined using the aluminium chloride colorimetric technique (Dewanto et al., 2002). For the TFC content analysis, 0.25 mL of the extracted sample was combined with 1.25 mL of distilled water and 0.075 mL of a 5% sodium nitrite solution. After the initial 5 min of reaction, 0.150 mL of 10% aluminium chloride solution was added and allowed to react for 6 min at room temperature. The mixture’s absorbance was then measured immediately at 510 nm by UV-VIS spectrophotometer with data analysis software (Libra S22, Biochrom, UK), along with 0.750 mL of distilled water and 0.5 mL of 1M sodium hydroxide. Based on the catechin standard curve, the TFC content was reported as mg catechin equivalents (CE) per g of dry weight (mg CE/g DW).

Determination of antioxidant activity (DPPH). The antioxidant activity was evaluated using the DPPH (2,2-diphenyl-1-picrylhydrazyl-hydrate) assay. When all of the free radicals are stopped by the antioxidants, the DPPH radical changes from purple to yellow, indicating that it is being inhibited. The approach of Turturică et al. (2015) was used to test the DPPH scavenging activity. In brief, 200 L of extract and 3.9 mL of 0.1 M DPPH solution were combined to create a combination. For 90 minutes, the combination was kept at 25°C in a dark environment. Using data analysis software (Libra S22, Biochrom, UK), a UV-VIS spectrophotometer measured the mixture absorbance at a 515 nm wavelength. Additionally, 3.9 mL of 0.1 M DPPH solution and 200 L of methanol were combined to provide a control. The mixture’s absorbance was then calculated.

The results obtained were expressed as mM Trolox/ g DW.

The DPPH Inhibition (%) was calculated using the following Eq. (1):

% Inhibition = (Ablank − Asample/Ablank) × 100 (1)

where: Ablank – absorbance of the control sample, Asample – absorbance of the sample.

Cheese processing

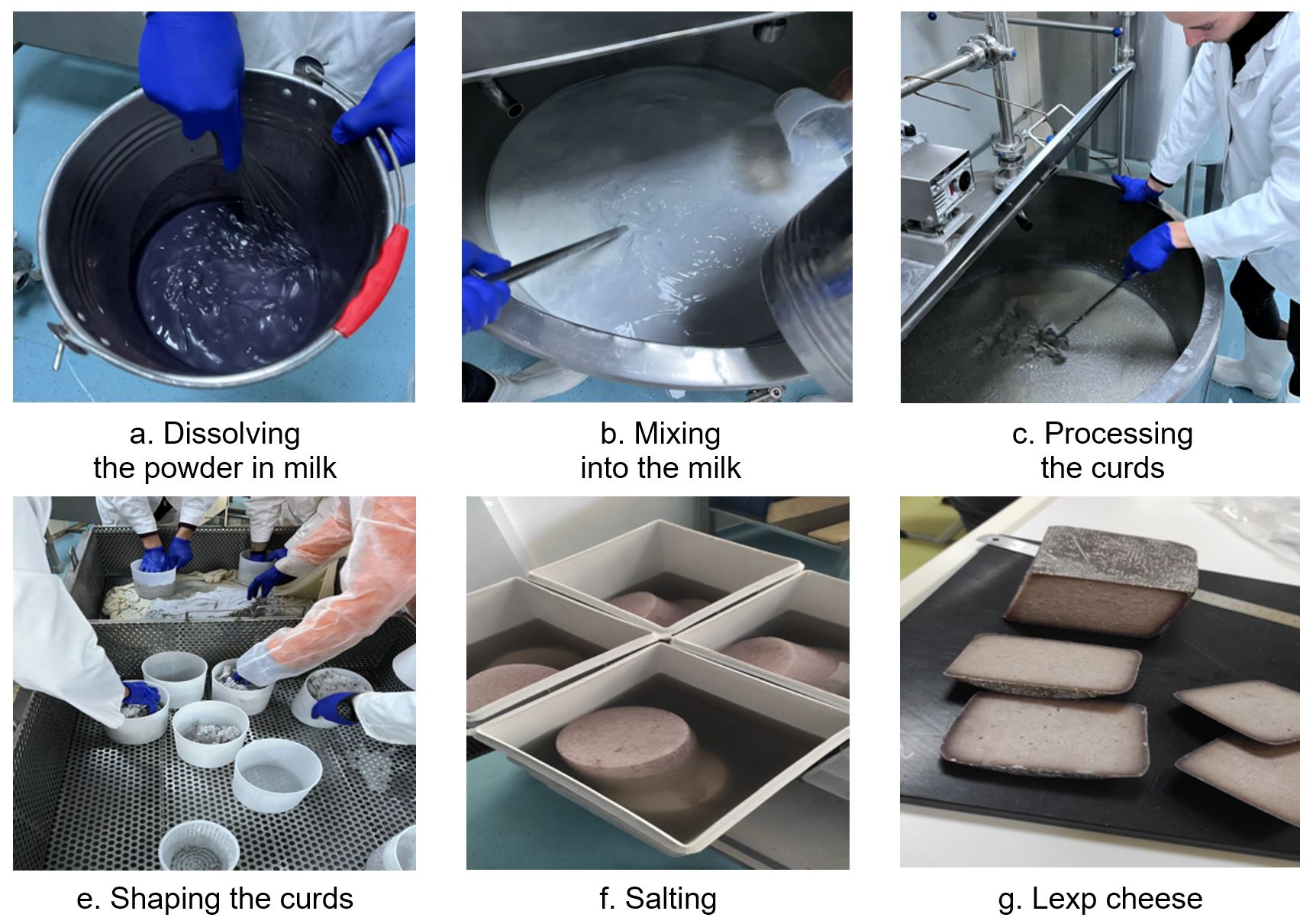

Three hundred litres of full-fat milk was used for the two varieties of Caciotta cheese. The technology for obtaining the cheese was that described by Rațu et al., 2022, with the addition that after adding the selected lactic cultures, the milk was divided into two batches as follows: 150 L of milk for the processing of Caciotta cheese (Lc); and 150 L of milk to which 2% Merlot grape skin powder has been added to obtain Caciotta cheese with added powder (Lexp) (Figure 1).

The processing steps to obtain cheese provided for the quantitative and qualitative reception of milk, followed by filtering. After filtering, the milk was pasteurized in a vat at a temperature of 60°C for 30 minutes. The milk was cooled to 36°C and the cultures were added (Mesophilic aromatic culture, type LD – FD-DVS FLORA DANICA by CHR HANSEN). The inoculation was carried out with a quantity of 50 U of culture for 500 L of milk (according to the production sheet). The milk was left to rest for 30 minutes. The next stage consisted of the formation of batches and the coagulation of the milk (35 – 36°C) where CHY – MAX M liquid was used (25 IMCU/l milk), which contains an enzyme that coagulates the milk with a very high specificity on the kappa-casein that it cleaves, obtaining a very good coagulum . The clotting process takes 35-40 minutes, followed by the first processing of the curds and the partial removal of the whey (30%). Next comes the second heating, which is done at a temperature of 42°C and involves processing the coagulum for 10-15 minutes (until the formed grain is dehydrated). It is left to rest in order to remove the whey (30%). The curds are placed in plastic mould (2 kg) and pressed (2 kg/kg) for 14 hours. During the first 8 hours, the cheese moulds are turned every 10 minutes. Next comes the salting stage (in 12% brine) and maturation (30 days at 12-14°C and RH 85-95%).

Evaluation of the cheese

Sensory, physical (pH, colour, and texture), and chemical (water, dry matter, F/DM [fat reported on dry matter content], protein, ash, and salt content) analyses were performed concerning the part of the qualitative analyses carried out to establish the qualitative parameters of both the product with the addition (cheese with grape skin powder – Lexp) and the control product (Lc).

Sensory evaluation of cheese

The Descriptive Sensory Analysis was conducted by a panel of 10 assessors, six of whom were men and four of whom were women. All participants in the University of Life Sciences, Iasi, formed a sensory panel. International standards were followed in the panel’s recruitment and screening processes (ISO 8586-1: 1993, ISO 8589:1998, ISO/DIS 13299:1998).

This well-trained, experienced panel made their measurements with a high degree of discrimination, sensitivity, and consistency (Land and Shepherd, 1988). All examiners underwent training in descriptive analysis and took part in creating the descriptive vocabulary for cheese.

A descriptive vocabulary was developed for two product categories, and the assessors evaluated the products for flavour, texture and mouth feel, appearance and odour (Stefanowicz et al., 2013). The lexicon was changed from the version created for the Cheese with GSP (in the colour).

Sixteen characteristics for the analyzed cheeses were chosen and carefully characterized for profiling using the QDA approach (Table 1). These characteristics include colour, odour (creamy, acid, buttery, fruity), taste (salty, acid, sweet, bitter, aftertaste), and texture (hardness, chewiness, rubbery, dryness, grainy). Continuous unstructured graphical scales were used to rate the attribute intensities. The scales were 10 cm long with verbal anchors at either end, with the left side representing the attribute’s lowest intensity (value 0) and the right side representing its highest intensity (value 10). The same type of scale as previously, which is anchored at both ends, was used to evaluate the overall quality of the cheeses: unlikeable (0) – significantly likeable (10).

Physical evaluation of cheese

pH was determined by potentiometric analysis, with the electrode being inserted directly into the cheese wheel (Model HI 99163).

The cheese colour was measured using a MINOLTA Chroma Meter model CR-410 using a CIE Lab scale following the International Commission on Illumination (CIE) recommendations.

Figure 1 – Processing steps to obtain Caciotta cheese with the addition of powder obtained from the skin of Merlot variety grapes

Table 1

Definitions of attributes for profiling the Caciotta cheese

|

Descriptor |

Characteristics |

|

Colour |

Visual intensity measurement |

|

Creamy odour |

Commercial-cream odour (30%) |

|

Acid odour |

A characteristic flavour of fermented milk products like yoghurt |

|

Buttery |

Flavour connected to butter |

|

Flowers/fruits |

The fragrant fusion of several fruity flavours, including red berries, juicy apples, and pineapple. It might also contain aromas connected to sweetened cultured dairy products such as fruit yoghurts. |

|

Salty |

Sodium chloride’s characteristic basic flavour when diluted in water (0.2%) |

|

Sweet |

Basic taste experience of sucrose |

|

Acid |

Fermented milk products’ flavour |

|

Bitter |

Flavour, basic caffeine taste in water (0.5%) |

|

Aftertaste |

Aftertaste that persisted after the sample was taken away |

|

Hardness* |

The amount of force required by the jaws to tear the sample in half |

|

Chewiness |

Length and duration of chewing the substance before swallowing |

|

Rubbery |

The sample’s capacity to reshape itself after pulling |

|

Dryness (moisture) |

Moisture in the sample, mouthfeel after four or five chews |

|

Grainy |

The sample’s capacity to splinter into parts |

|

Overall quality |

General impression based on what people like and dislike |

Anchoring points: non-intensive–very intensive; *low–high

Specific cheese moulds were divided into two halves, and colour assessments were made at various locations on the interior surface of the cheese. The samples were evaluated for lightness (L*) and yellow/blue chromaticity (b*), with the optical system’s aperture size set at 3 mm.

The Chroma parameters were read using A* (red (> 0) to green (< 0) colour), b* (yellow (> 0) to blue (<0) colour), and L* (black: L* = 0 and white: L* = 100). The results were expressed in triplicate, following equipment calibration against a white plate.

The colour was described by hue angle for quadrant I (+a*, +b*), where 0° or 360° indicated red colour, 90° indicated yellow colour, 180° indicated green colour, and 270° indicated blue colour (Eq. 2).

Hue angle = arctan(b*/a*) (2)

The purity or saturation of the colour, also known as chroma, was also determined using the formula described by Dag et al. (2017) (Eq. 3).

![]()

Chemical evaluation of cheese

Cheese samples were analyzed for moisture, dry matter, fat, FDM, and ash according to the methods described in AOAC (2000).

The protein content was analyzed according to the method describe by Simeanu et al. (2015). The concentration of sodium chloride (salt content) was measured by titration with AgNO3 (International Standard FIL-IDF 88/A:1988).

The phytochemical profile was determined according to the methods described in previous section.

The phytochemical content and the antioxidant activity of cheese

The methods used to determine the phytochemical profile of the two varieties of cheese as well as the antioxidant activity are described in previous section. In the case of the antioxidant activity of cheeses, the radical scavenging activity of the cheese samples was also expressed as an inhibition percentage and calculated using the formula described by Elgaml et al. (2018) (Eq. 4).

DPPH radical scavenging activity (%) = (1 – Asample / Ablank) x 100 (4)

where: Ablank-absorbance of the control sample, Asample– absorbance of the sample.

Statistical analysis

SPSS (Version 20.0) software was used for statistical analysis employing ANOVA, and significant means were compared using Duncan’s test at P < 0.05.

RESULTS

Extraction of GSP and its characterization

In this investigation, ethanol (at a concentration of 80%) and citric acid (at a concentration of 1%) were used as solvents in an ultrasonic-assisted extraction procedure. Table 2 displays the results of an analysis of the antioxidant activity and content of physiologically active components in an extract of GSP. Total anthocyanins content was 1.562±0.054 mg C3G/g DW, total flavonoid content was 10.936±0.195 mg CE/g DW, and total phenolic content was 22.944±0.303 mg GAE/g DW. Inhibition of the DPPH radical by the GSP extract was 79.082 ±0.035 %, and the extract’s radical-scavenging activity was 21.034±0.102 mM Trolox/g DW.

Sensory evaluation of cheese

Mean ratings of intensity for descriptive features are shown in Table 3. According to our analysis of variance, there were statistically significant differences (P < 0.05) in the levels of many characteristics. These included colour, flowers/fruits, sweet taste, acid taste, hardness, chewiness, rubbery and grainy.

Physical evaluation of cheese

As expected, changes also occurred in terms of pH value and colour (Table 4). Therefore, the differences that appeared in the pH value were significant (P < 0.05), the average value for Lc being 5.31±0.01, while that of Lexp was 5.20±0.01.

Table 2

Phytochemical content and antioxidant activity of the GSP extract

|

Sample |

TAC1 (mg C3G/g DW) |

TFC2 (mg CE/g DW) |

TPC3 (mg GAE/g DW) |

DPPH4 (mM Trolox /g DW) |

Inhibition % |

|

GSP5 |

1.562±0.054 |

10.936±0.195 |

22.944±0.303 |

21.034±0.102 |

79.082 ±0.035 |

1 – Total Anthocyanins Content; 2 – Total Flavonoids Compounds; 3 – Total Phenolic Compounds; 4 – Antioxidant Activity (DPPH);5 – Grape Skin Powder.

Table 3

Quantitative descriptive analysis of Lc and Lexp cheeses

|

Specification |

Type of cheese |

P-value |

|

|

Lc |

Lexp |

||

|

Colour |

4.2a |

5.5b |

0.0217 |

|

Flavour |

7.3a |

7.8a |

0.1824 |

|

Acid odour |

3.1a |

3.4a |

0.4762 |

|

Buttery |

5.6a |

4.9a |

0.1479 |

|

Creamy odour |

4.3a |

3.9a |

0.3954 |

|

Flowers/fruits |

4.8a |

6.2b |

0.0049 |

|

Salty taste |

3.2a |

2.8a |

0.2269 |

|

Sweet taste |

1.4a |

2.5b |

0.0025 |

|

Acid taste |

1.3a |

1.7a |

0.1448 |

|

Bitter taste |

1.9a |

2.4a |

0.1372 |

|

Hardness |

2.8a |

3.6b |

0.0274 |

|

Chewiness |

4.1a |

4.9b |

0.0403 |

|

Rubbery |

6.1a |

4.9b |

0.0197 |

|

Dryness |

5.1a |

4.4a |

0.0637 |

|

Grainy |

4.2a |

5.1b |

0.0498 |

|

Overall quality |

5.8a |

5.3a |

0.3220 |

Letters indicate a comparison between each variety of cheese; means marked with the same letters in each row do not show significant differences (ANOVA test, P < 0.05)

Table 4

pH and colour traits of Lc and Lexp cheeses stored for 30 days

|

Specification |

Type of cheese |

P-value |

|

|

Lc |

Lexp |

||

|

pH |

5.31±0.01a |

5.20±0.01b |

0.0014 |

|

L* |

68.32±0.04a |

53.57±0.03b |

1.2811E-09 |

|

a* |

-1.17±0.34a |

8.43±0.03b |

9.3067E-06 |

|

b* |

11.73±0,01a |

6.58±0.06b |

1.7423E-07 |

|

C* |

11.80±0.04a |

10.70±0.06b |

0.0001 |

|

h° |

-1.47±0.03a |

0.66±0.03b |

1.9664E-07 |

L* value is the lightness coefficient; b* value indicates the position on the blue (−) to yellow (+) axis; C* (chroma); h◦ (hue angle). a,b describes the comparison between each variety of cheese; means marked with the same letters in each row do not show significant differences (ANOVA test, P < 0.05)

The introduction of GSP, resulted in a significantly lower brightness (L*) value in the Lexp (53.57±0.03) sample (P < 0.05). In the case of the Lexp cheese, an increase in the parameter a* (8.43±0.0) was seen as expected (P < 0.05). The parameter b* in the Lexp (6.58±0.06) eventually reduced dramatically (P < 0.05) compared with Lc (11.73±0.01). The average for the Chroma findings was 10.70±0.06 for Lexp and 11.80±0.04 for Lc. The differences were similarly significant (P < 0.05). The Hue angle parameter in the case of Lc were -1.47±0.03 and 0.66±0.03 for Lexp, with a significant difference (P < 0.05).

Chemical evaluation of cheese

Table 5 shows the chemical composition of the two types of cheese analyzed. Regarding the dry matter level it can be seen that the differences were significant (P < 0.05).

The data regarding the fat content revealed no difference between the two groups analyzed (P > 0.05). For the protein level, an average of 24.92±0.08% was recorded at Lc and 25.16±0.12% for Lexp (P > 0.05). Significant differences were found in the case of ash content (P < 0.05). Regarding the salt content, no differences were noted (P > 0.05).

The phytochemical content and the antioxidant activity of cheese

Caciotta cheese with value-added was obtained using grape skin powder (derived from Merlot grapes) at a rate of 2%. The effects of GSP addition to cheese were evaluated by comparing the bioactive chemical content of the control (Lc) and experimental (Lexp) cheese samples. Table 6 displays the antioxidant activity and phytochemical content of the Caciotta cheese (Lc and Lexp).

Differences between cheeses were statistically significant (P < 0.05). Predictably, Lexp had more bioactive components than the control cheese (Lc). In the case of TAC, for Lexp the average value obtained was 5.483±0.443 mg C3G/100 g DW, while in Lc it was not identified. Significant differences (P < 0.05) were also noted in the case of TFC where for Lc the level was 0.422±0.063 mg CE/g DW compared to 0.717 ±0.042 mg CE/g DW as it was in Lexp. Significant differences can also be noted in the case of TPC where for Lexp the average value was 5.182 ±0.558 mg GAE/g DW compared to 3.136±0.507 mg GAE/g DW as it was in Lc.

Table 5

Chemical composition of Lc and Lexp processed cheese stored for 30 days

|

Parameters |

Type of cheese |

Interval |

Variance |

P-value |

|

|

Dry matter (%) (DM) |

Lc |

61.88±0.09a |

61.72 – 62.02 |

0.24 |

0.00024 |

|

Lexp |

64.69±0.21b |

64.30 – 65.02 |

0.56 |

||

|

Fat (%) |

Lc |

34.12±0.08a |

33.98 – 34.27 |

0.43 |

0.41237 |

|

Lexp |

33.98±0.21a |

33.89 – 34.17 |

0.69 |

||

|

Fat in dry matter (FDM) (%) |

Lc |

55.15±0.19a |

54.90 – 55.52 |

0.60 |

0.00109 |

|

Lexp |

52.52±0.40b |

51.58 – 52.91 |

1.36 |

||

|

Protein (%) |

Lc |

24.92±0.08a |

24.76 – 25.01 |

0.55 |

0.41233 |

|

Lexp |

25.16±0.12a |

25.12 – 25.38 |

0.78 |

||

|

Ash (%) |

Lc |

4.33±0.04a |

4.21 – 4.39 |

1.69 |

0.00324 |

|

Lexp |

5.92±0.08b |

5.77 – 6.01 |

2.21 |

||

|

Salt content (%) |

Lc |

1.92±0.04a |

1.86 – 2.01 |

4.04 |

0.53570 |

|

Lexp |

1.88±0.05a |

1.78 – 1.96 |

4.84 |

Values with different letters for the same parameter in the column are significantly different (P < 0.05).

Table 6

Phytochemical profile of Lc and Lexp processed cheese stored for 30 days

|

Parameters |

Type of cheese |

Interval |

Variance |

P-value |

|

|

TAC, mg C3G/100 g DW |

Lc |

– |

– |

– |

– |

|

Lexp |

5.483±0.443 |

4.661 – 6.132 |

13.69 |

||

|

TFC, mg CE/g DW |

Lc |

0.422±0.063a |

0.313 – 0.523 |

25.95 |

0.03269 |

|

Lexp |

0.717 ±0.042b |

0.634 – 0.722 |

10.18 |

||

|

TPC, mg GAE/g DW |

Lc |

3.136±0.507a |

2.265 – 4.021 |

28.00 |

0.04326 |

|

Lexp |

5.182 ±0.558b |

4.191 – 6.121 |

18.64 |

||

|

Antioxidant activity, mM Trolox/g DW |

Lc |

1.451±0.067a |

1.345 – 1.574 |

7.96 |

0.00018 |

|

Lexp |

2.676 ±0.063b |

2.566 – 2.785 |

4.09 |

||

|

Antioxidant activity (%) |

Lc |

2.45±0.051a |

2.38 – 2.55 |

3.63 |

5.5293E-06 |

|

Lexp |

5.85±0.092b |

5.67 – 5.98 |

2.73 |

Values with different letters for the same parameter in the column are significantly different (P < 0.05).

The differences were also maintained in the case of antioxidant activity, where for Lc the value was 2.45±0.051% versus 5.85±0.092% (Lexp).

DISCUSSION

Characterization of grape skin powder

Scientific research is still needed to optimize the procedure for extracting biologically active components from grape skin. Extraction strategies for bioactive compounds have been the subject of numerous investigations [9,25]. These methods include solid-liquid extractions, mechanical agitation, and solvent extraction (ethanol and methanol extraction). Extraction efficiency, time, quality, and solvent consumption can all be improved by carefully selecting the solvent. In the current investigation, ethanol (80%) and citric acid (1%), both of which served as solvents, were used in the ultrasound-assisted extraction procedure. However, our findings can be compared to those of Constantin et al. (2015), who used a conventional method (at 28°C for 2 hours) to extract the biologically active components from the skin of Vitis vinifera ”Fetească neagră ”grapes and reported anthocyanins at 18.54±0.34 mg C3G/g DW, flavonoids at 2.27±0.20 mg CE/g DW, polyphenols at 7.42±0.06 mg GAE/g DW and antioxidant activity of 4.89±0.02 µM Trolox/g DW using the ABTS method.

Ivanova et al. (2010) also reported similar results for grape skin extract flavonoids, with a value of 6.90±0.42 mg CE/g DW after extraction with 80% ethanol. Negro et al. (2003) reported a lower concentration of TPC in red grape skin, 33.3±0.3 mg GAE/100 g DW, after extracting the chemicals with 80% ethanol and acetic acid. In contrast to the present findings, Manconi et al. (2016) reported a larger amount of phenolic compounds from grape pomace of 126±30 mg GAE/g DW and a poorer radical scavenging activity by utilizing a DPPH assay of 0.91±0.17 mM Trolox/g DW. However, the origin of the raw materials, the cultivar (i.e., genetic and environmental factors), agronomic practices, various extraction conditions (type of solvent, pH, temperature), and procedures, as well as the measuring method used, can all affect the phytochemical content of GSP extracts.

Sensory evaluation of cheese

The addition of GSP to milk in making cheese has been shown to have a significant impact on sensory characteristics. One index that underwent significant changes was colour. Components released in the cheese caused a distinctive purple and brown marbled effect that was absent from the reference sample due to the phenolic concentration of the powder made from the skin of Merlot grapes. Also, the addition of GSP in cheese positively impacted the aroma and taste, this also being due to the phenolic compounds. In the case of Lexp, improvements were also observed in terms of bitter taste, hardness, chewiness, and graininess, due to the fact that the addition of GSP increased the content of dry matter, which led to a reduction in the water level.

However, numerous studies have shown that adding phenolic compounds to dairy products changes their organoleptic characteristics. In some instances, phenols were also responsible for distinct off-flavours caused by protein interaction via Maillard reactions (Luck et al., 1994); oxidation from the heating of milk (Dumont et al., 1974); or even when they were added as flavouring agents (Maga, 1988).

On the other hand, numerous studies attest that the bioactive compounds present in vegetable by-products significantly improve sensory properties. In this regard, Costa et al. (2018) reported that spreadable and Primosale cheese could be identified as having a marbled appearance along with the flavours of astringency, fibrousness, friability, acidity, saltiness, and adhesiveness when red and white grape pomace were added. The pomace increased the product’s aromatic complexity. Additionally, improved dispersion in the cheese may have lowered the intensity of some sensations, such as earthy, vinous, and taste sensations associated with the inclusion of the powder.

Additionally, Khalid et al. (2021) assessed whether adding cereal by-products like wheat germ and oat bran improved the sensory appearance of soft cow’s milk cheese. Zayan et al. (2021) added tomato skin powder to an assortment of cheeses and observed an improvement in sensory characteristics increasing acceptability. On the other hand, El-Messery et al. (2019) added mandarin peel extract to processed cow’s milk cheese, resulting in a decrease in the degree of acceptability. However, the acceptance of the product by consumers must be considered. The consumer may be more appreciative of the product because of its health-promoting qualities if they are informed about the by-product’s addition and how it may affect the sensory score assigned to it.

Physical evaluation of cheese

From a physical point of view, the products were analyzed to establish the pH value, the colour, and the parameters that define the texture. The addition of GSP led to a decrease in pH in Lexp compared to the value identified in Lc. However, Costa et al. (2018) also noted a decrease in pH value in the case of cheeses fortified with white and red wine grape pomace. The pH level likely gradually decreased due to the emulsifying salts’ decomposition and/or their interactions with protein while stored.

According to Da Silva et al. (2017), adding the grape extract to yogurt in amounts of 1.5 and 3.0 g/L did not affect the titratable acidity (%) or pH. Contrarily, according to Brahmi et al. (2021), adding grape seed extract to yoghurt caused a modest drop in the pH levels of the yoghurt samples. Because of the presence of anthocyanins, adding the powder to milk entirely altered the product’s hue. The brightness (L*) value in the Lexp sample dramatically decreased with the addition of GSP. As anticipated, an increase in parameter a* was observed in the case of the Lexp product. This results from anthocyanins, responsible for giving GSP its red colour. The parameter b* in the GSP-enriched product eventually declined considerably. Similar to our research on colour in a study on yoghurt, Demirkol et al. (2018) found that while the a* value increased, the L and b* values declined. According to Hayta et al. (2014) and Nakov et al. (2020), adding grape pomace powder to samples of breads and cakes significantly reduced their brightness (L*).

Chemical evaluation of cheese

Fortification with GSP generated changes in the chemical composition. Lexp cheese had a significantly higher moisture content compared to Lc. In a study by Gabr et al. (2016) on soft cheese mixed with black rice powder at 5%, 10%, or 15% there were no statistically significant variations in the moisture content. Although each flour had a unique ability to retain water (Robertson et al., 2000), literature data also supported the finding that, in general, adding vegetable flours to fresh cheese resulted in a reduction in moisture content (Dibazar et al., 2016). Han et al. (2011) noted an improvement in the chemical composition of dairy products when adding powder made from grape skin or grape pomace. They found that dairy products containing grapes and their derivatives significantly increase the amount of phenolic compounds in their matrix, which can bind to proteins and carbohydrates. However, in all these studies it is highlighted that no significant changes occur regarding the gross chemical composition. In our study, in the case of ash content, a higher level was identified in Lexp compared to that of Lc. This can be because grape skins are a rich source of minerals such as potassium, calcium, and magnesium (Galanakis, 2017).

In terms of phytochemical profile, the Lc sample lacked anthocyanins and had a low flavonoid concentration. Adding GSP (2%) to the cheese was observed to boost the levels of bioactive chemicals. The resulting sample also displayed functional characteristics (total phenolic content and antioxidant activity) at much greater levels of bioactive chemicals than the control sample (Lc). TPC was higher in Lexp after 2% (w/w) GSP was added, compared to Lc. The higher amounts of bioactive chemicals in the Lexp also contributed to its superior antioxidant activity compared to that of the Lc.

Han et al. (2011), who observed that dairy products with grapes and their derivatives introduced to their matrix a large number of phenolic compounds, which can associate with proteins and carbohydrates, also noted an improvement in the chemical composition of dairy products to which powder obtained from the skin of grapes or grape pomace powder was added. The addition of red and white Chardonnay and Barbera grape pomaces, both before and after distillation, to Cheddar and Toma-like cheeses was studied by Marchiani et al. (2016). They observed variations in moisture in the manufactured cheeses and between grape pomaces. To change the characteristics and raise the total phenolic content, antioxidant activity, and nutritional value of the produced cheeses, including Petit Suisse, Primosale, Chihuahua, and spreadable cheeses, Marchiani et al. (2016) added grape derivatives, either to the cheese milk or the curd. A minimum inclusion of 1.6% grape pomace is typically needed to boost the antioxidant activity in cheeses significantly. However, the amount used, the grape type, the grape derivative (seed, pomace, or juice), and its physical condition (powder or extract) all impacted the cheeses’ overall phenolic content and antioxidant activity. The number of polyphenolic chemicals and antioxidant activity in grape seeds is typically higher. According to research by Da Silva et al. (2015), grape seed extract has a concentration of polyphenolic chemicals twice as high as grape skin.

CONCLUSIONS

The results of this study could have a significant effect on the cheese industry since they show that utilizing natural, plant-based components can enhance the general quality and nutritional value of cheeses. As a result, this research aims to provide crucial information on using grape skin powder as a beneficial ingredient in cheese manufacture. Although there are many advantages to using grapes and their derivatives in dairy products, paying particular attention to how they affect acidity and sensory qualities is vital. This will guarantee that the finished product matches consumers’ expectations for flavour, texture and utilitarian qualities. However, the dairy industry can take advantage of this exciting new potential to produce both nutritious and delicious products by carefully balancing these elements.

Author Contributions: Conceptualization, R.N.R., P.M.C and I.D.V.; methodology, P.M.C., M.G.U., R.M.R.R., R.N.R., V.N.A., I.C.C.; software, V.N.A., A.N.P., R.M.R.R.,; validation, R.N.R., P.M.C., I.D.V.; formal analysis, R.N.R., V.N.A., P.M.C.; investigation, R.N.R., I.V., M.G.U; data curation, R.N.R., F.L., I.C.C; writing – original draft preparation, R.N.R., M.G.U., A.N.P., R.M.R.R.; writing – review and editing, R.N.R.., F.L., P.M.C; visualization, R.N.R., F.L., A.N.P.; supervision, R.N.R. All authors declare that they have read and approved the publication of the manuscript in this present form.

Funding: There was no external funding for this study.

Conflicts of Interest: There was no conflicts of interest.

REFERENCES

Ayar, A.; Siçramaz, H.; Öztürk, S.; Öztürk Yilmaz, S. Probiotic properties of ice creams produced with dietary fibres from by- products of the food industry. Journal of Dairy Technology. 2017, 71, 174-182. https://doi.org/10.1111/1471-0307.12387.

Bedoic, R.; Cosic, B.; Duic, N. Technical potential and geographic distribution of agricultural residues, co-products and by-products in the European Union. The Science of the Total Environment. 2019, 686, 568-579. https://doi.org/10.1016/j.scitotenv.2019.05.219.

Brahmi, F.; Merchiche, F.; Mokhtari, S.; Smail, L.; Ghemghar, H.; Yalaoui‐Guellal, D.; Achat, S.; Elsebai, M.F.; Madani, K.; Boulekbache, L. Optimization of some extraction parameters of phenolic content from apple peels and grape seeds and enrichment of yogurt by their powders: a comparative study. Journal of Food Processing and Preservation. 2021, 45, 15126. https://doi.org/10.1111/jfpp.15126.

Caldeira, C.; De Laurentiis, V.; Corrado, S.; van Holsteijn, F.; Sala, S. Quantification of Food Waste per Product Group along the Food Supply Chain in the European Union: A Mass Flow Analysis. Resources, Conservation and Recycling. 2019, 149, 479-488. https://doi.org/10.1016/j.resconrec.2019.06.011.

Câmara, J.S.; Lourenço, S.; Silva, C.; Lopes, A.; Andrade, C.; Perestrelo, R. Exploring the potential of wine industry by-products as source of additives to improve the quality of aquafeed. Microchemical Journal, Devoted to the Application of Microtechniques in All Branches of Science. 2020, 155, 104758. https://doi.org/10.1016/j.microc.2020.104758.

Coelho, M.C.; Ghalamara, S.; Pereira, R.; Rodrigues, A.S.; Teixeira, J.A.; Pintado, M.E. Innovation and Winemaking By-Product Valorization: An Ohmic Heating Approach. Processes. 2023, 11, 495. https://doi.org/10.3390/pr11020495.

Costa, C.; Lucera, A.; Marinelli, V.; Del Nobile, M.A.; Conte, A. Influence of different by-products addition on sensory and physicochemical aspects of Primosale cheese. Journal of Food Science Technology. 2018, 55, 4174-4183. https://doi.org/10.1007%2Fs13197-018-3347-z.

Da Silva, D.F.; Matumoto-Pintro, P.T.; Bazinet, L.; Couillard, C.; Britten, M. Effect of commercial grape extracts on the cheese-making properties of milk. Journal of Dairy Science. 2015, 98, 1552-1562. https://doi.org/10.3168/jds.2014-8796.

Da Silva, D.F.; Junior, N.N.T.; Gomes, R.G.; Pozza, M.S.S.; Britten, M.; Matumoto-Pintro, P.T. Physical, microbiological and rheological properties of probiotic yogurt supplemented with grape extract. Journal Food Science and Technology. 2017, 54, 1608-1615. https://doi.org/10.1007/s13197-017-2592-x.

Díaz-Vela, J.; Totosaus, A.; Pérez-Chabela, M.L. Integration of agroindustrial Co-products as functional food ingredients: Cactus pear (O puntia ficus indica) flour and pineapple (Ananas comosus) peel flour as fiber source in cooked sausages inoculated with lactic acid bacteria. Journal of Food Processing and Preservation. 2015, 39, 2630-2638. https://doi.org/10.1111/jfpp.12513.

Dibazar, P.; Khosrowshahi, A.A.; Zomorodi, S. Optimization grape fiber and chitosan amounts in fruit yoghurt using response surface methodology (RSM). Journal of food science and technology. 2016, 13, 75-88.

Difonzo, G.; Antonino, C.; Squeo, G.; Caponio, F.; Faccia, M. Application of Agri-Food by-Products in Cheesemaking. Antioxidants. 2023, 12. https://doi.org/10.3390/antiox12030660.

Dumont, J.P.; Roger, S.; Cerf, P.; Adda, J. Study of volatile neutral compounds present in Camembert (in French). Le Lait. 1974, 54, 501-516.

Dos Santos, K.M.; de Oliveira, I.C.; Lopes, M.A.; Cruz, A.P.G.; Buriti, F.C.; Cabral, L.M. Addition of grape pomace extract to probiotic fermented goat milk: the effect on phenolic content, probiotic viability and sensory acceptability: Grape pomace extract effect on fermented goat milk. Journal of the Science of Food and Agriculture. 2017, 97, 1108-1115. https://doi.org/10.1002/jsfa.7836.

Dwyer, K.; Hosseinian, F.; Rod, M. The Market Potential of Grape Waste Alternatives. Journal of Food Resources. 2014, 3, 91. https://doi.org/10.5539/jfr.v3n2p91.

El-Messery, T.M.; El-Said, M.M.; Farahat, E.S.A. Production of functional processed cheese supplemented with nanoliposomes of mandarin peel extract. Pakistan Journal of Biological Sciences. 2019, 22, 247-256. https://doi.org/10.3923/pjbs.2019.247.256.

FAO. The State of Food and Agriculture 2019. Moving forward on food loss and waste reduction. Rome. 2019. Licence: CC BY-NC-SA 3.0 IGO.

Gabr, A.S.M.; Mahgoub, S.A.; Satar, A.S.A.; Shehata, W.M. Evaluation of healthy soft cheese produced by buffalo’s milk fortified with black rice powder. International Journal of Dairy Science. 2016, 11, 11-19. https://doi.org/10.3923/ijds.2016.11.19.

Gaglio, R.; Barbaccia, P.; Barbera, M.; Restivo, I.; Attanzio, A.; Maniaci, G.; Di Grigoli, A.; Francesca, N.; Tesoriere, L.; Bonanno, A.; Moschetti, G.; Settanni, L. The Use of Winery By-Products to Enhance the Functional Aspects of the Fresh Ovine “Primosale” Cheese. Foods. 2021, 10, 461. https://doi.org/10.3390/foods10020461.

Galanakis, C.M. Handbook of grape processing by-products: Sustainable solutions. Academic Press. 2017

Han, J.; Britten, M.; St-Gelais, D.; Champagne, C.P.; Fustier, P.; Salmieri, S.; Lacroix, M. Polyphenolic compounds as functional ingredients in cheese. Food Chemistry. 2011, 124, 1589-1594. http://dx.doi.org/10.1016/j.foodchem.2010.08.021.

Hassan, Y.I.; Kosir, V.; Yin, X.; Ross, K.; Diarra, M.S. Correction to Grape Pomace as a Promising Antimicrobial Alternative in Feed: A Critical Review. Journal of Agricultural and Food Chemistry. 2020, 68, 12174. https://doi.org/10.1021/acs.jafc.0c06361

Hayta, M; Özugur, G.; Hakiye E.; Ibrahim S ̧ T. Effect of grape (Vitis Vinifera L.) pomace on the quality, Total phenolic content and anti-radical activity of bread. Journal of Food Processing and Preservation. 2014, 38, 980-986. http://doi.org/10.1111/jfpp.12054.

Kaderides, K.; Mourtzinos, I.; Goula, A.M. Stability of Pomegranate Peel Polyphenols Encapsulated in Orange Juice Industry By-Product and Their Incorporation in Cookies. Food Chemistry. 2020, 310, 125849. https://doi.org/10.1016/j.foodchem.2019.125849.

Kandylis, P.; Dimitrellou, D.; Moschakis, T. Recent Applications of Grapes and Their Derivatives in Dairy Products. Trends in Food Science & Technology. 2021, 114, 696-711. https://doi.org/10.1016/j.tifs.2021.05.029.

Karnopp, A.R.; Margraf, T.; Maciel, L.G.; Santos, J.S.; Granato, D. Chemical Composition, Nutritional and in Vitro Functional Properties of by-Products from the Brazilian Organic Grape Juice Industry. International Food Research Journal. 2017, 24, 207-214.

Khalid, N.T.; Shaymaa, R.K.; Luma Khairy, H. Effect of incorporated soft cheese with wheat germ extracts quality and on shelf life. Indian Journal of Ecology. 2021, 48, 244-248.

Land, D.G.; Shepherd, R. Scaling and ranking methods. In: Piggott J.R. (ed): Sensory Analysis of Foods. 2nd Ed. Elsevier Science Publishers, London, 1988, 155-185.

Lee, J.; Durst, R.W.; Wrolstad, R.E. Determination of total monomeric anthocyanin pigment content of fruit juices, beverages, natural colorants, and wines by the pH differential method: collaborative study. Journal of AOAC International. 2005, 88, 1269-1278.

Luck, G.; Liao, H.; Murray, N.J.; Grimmer, H.R.; Warminski, E.E.; Williamson, M.P.; Lilley, T.H.; Haslam, E. Polyphenols, astringency and proline-rich proteins. Phytochemistry. 1994, 37, 357-371.

Maga, J.A. Food utilization of cereal‐based fermentation fiber/protein by‐products. Food Reviews International. 1988, 4, 331-349. https://doi.org/10.1080/87559128809540836.

Marchiani, R.; Bertolino, M.; Belviso, S.; Giordano, M.; Ghirardello, D.; Torri, L.; Zeppa, G. Yogurt enrichment with grape pomace: effect of grape cultivar on physicochemical, microbiological and sensory properties. Journal of Food Quality. 2016, 39, 77-89.

Nakov, G.; Brandolini, A.; Hidalgo, A.; Ivanova, N.; Stamatovska, V.; Dimov, I. Effect of grape pomace powder addition on chemical, nutritional and technological properties of cakes. Lebensmittel-Wissenschaft Und Technologie. 2020, 134, 109950. https://doi.org/10.1016/j.lwt.2020.109950.

Pedroza, M.A.; Carmona, M.; Salinas, M.R.; Zalacain, A. Use of Dehydrated Waste Grape Skins as a Natural Additive for Producing Rosé Wines: Study of Extraction Conditions and Evolution. Journal of Agricultural and Food Chemistry. 2011, 59, 10976-10986. https://doi.org/10.1021/jf202626v.

Rațu, R.N.; Lipșa, F.D.; Postolache, A.N.; Veleșcu, I.D.; Usturoi, A.; Usturoi, M.G. Quality conditions of an assortment of semi-hard cheese – Caciotta. Animal and Food Sciences Journal. 2022, 77, 131-136.

Robertson, J.A.; de Monredon, F.D.; Dysseler, P.; Guillon, F.; Amado, R.; Thibault, J.F. Hydration properties of dietary fibre and resistant starch: a European collaborative study. LWT. 2020, 33, 72-79.

Simeanu, D.; Creangă, Ş.; Simeanu, C. Research on the meat quality produced by Polyodon Spathula sturgeons’ species related to human nutritional requirements. Research Journal of Biotechnology. 2015, 10, 36-43.

Stefanowicz, P. Sensory Evaluation of Food Principles and Practices. Journal of Wine Research. 2013, 24, 80-90. https://doi.org/10.1080/09571264.2013.764662.

Sousa, E.C.; Duarte Alexandrino, C.; Carioca, J.O.B.; Rodrigues, S.P.; Uchôa-Thomaz, A.M.A.; Rodrigues, L.L.; Lima, A.; Ferreira, P.A.T.; Morais, S.M.; Rodrigues, A.L.M. Chemical Composition and Bioactive Compounds of Grape Pomace (Vitis vinifera L.), Benitaka Variety, Grown in the Semiarid Region of Northeast Brazil. Food Science Technology. 2014, 34, 135-142.

Tseng, A.; Zhao, Y. Wine Grape Pomace as Antioxidant Dietary Fibre for Enhancing Nutritional Value and Improving Storability of Yogurt and Salad Dressing. Food Chemistry. 2013, 138, 356-365. https://doi.org/10.1016/j.foodchem.2012.09.148.

Yadav, K.; Bajaj, R.K.; Mandal, S.; Saha, P.; Mann, B. Evaluation of total phenol content and antioxidant properties of encapsulated grape seed extractin yoghurt. International Journal of Dairy Technology. 2018, 71, 96-104. https://doi.org/10.1111/1471-0307.12464.

Zayan, A.F.; Bakry, A.M.; AbdulAlim, T.S.; Radwan, H.M.; Abouelnaga, M.; Safdar, W.; Campelo, H.; Rashed, M.A.; Rahman, R.T.; Muhammad, Z. Novel processed cheese production using lycopene oil obtained by green-extraction technique of tomato peels waste. Nutrition and Food Processing. 2021, 4, 35. https://doi.org/10.31579/2637-8914/035.

Zeppa, G.; Tedesco, M.; Bertolino, M.; Çilek Tatar, B. Grape Pomace as a New Coagulant for Tofu Production: Physicochemical and Sensory Effects. Foods. 2021, 10, 1857. https://doi.org/10.3390/foods10081857.

ISO 8586-1: 1993. Sensory analysis – General guidance for the selection, training and monitoring of assessors – Part 1: Selected Assessors. International Organization for Standardization, Geneva.

ISO 8589:1998. Sensory analysis – General guidance for the design of test rooms. International Organization for Standardization, Geneva.

ISO/DIS 13299:1998. Sensory analysis – Methodology – General guidance for establishing a sensory profile. International Organization for Standardization, Geneva.

Academic Editor: Prof. Dr. Daniel Simeanu

Publisher Note: Regarding jurisdictional assertions in published maps and institutional affiliations ALSE maintain neutrality.

Arsenoaia Vlad Nicolae, Cârlescu Petru Marian, Crivei Ioana Cristina, Lipșa Florin Daniel, Postolache Alina Narcisa, Radu-Rusu Răzvan Mihail, Rațu Roxana Nicoleta, Usturoi Marius Giorgi, Veleșcu Ionuț Dumitru